Filter material for air purification and preparation method thereof

A filter material and air purification technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of submicron particle effects are not very obvious, and achieve simple preparation process, small air resistance, and easy disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation method of the above-mentioned filter material for air purification of the present invention comprises the following steps: firstly prepare the central layer of nano-polyacrylonitrile fiber non-woven fabric, dissolve the polyacrylonitrile particles in N-N dimethylformamide (DMF), and prepare A polyacrylonitrile solution with a mass percentage of 12-16%, and then inject the prepared polyacrylonitrile solution into the multi-nozzle electrospinning equipment, adjust the voltage value to 22kV, and continuously spin for 4-6 hours to prepare a uniform White nano-polyacrylonitrile fiber non-woven fabric, polyacrylonitrile fiber diameter 150-200nm. The nano-polyacrylonitrile fiber non-woven fabric can be prepared in large quantities for standby use. The thickness of one layer of polyacrylonitrile fiber nonwoven fabric is 3-5mm; Then the prepared nanofiber nonwoven fabric is cut into sheets; Nano activated carbon particles are dispersed in polyvinyl alcohol aqueou...

Embodiment 1

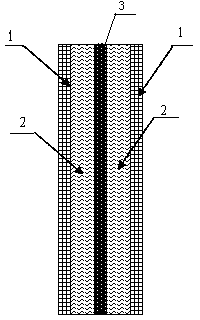

[0023] A filter material for air purification, which is a multi-layer composite structure, consisting of a central layer, a symmetrically arranged polyester fiber felt middle layer, and a stainless steel protective net outer layer. The thickness of the central layer is 15mm, and it is made of nano activated carbon particles The coated nano-polyacrylonitrile (PAN) fiber non-woven fabric layer is superimposed, in which the diameter of the nano-PAN fiber is 150-200 nanometers, the diameter of the nano-activated carbon particle is 30nm, the thickness of the middle layer of polyester fiber felt is 10mm, and the outer layer of stainless steel mesh For the protective layer, five layers of material are compressed and fixed by bolts. The thickness of the single-layer nano-polyacrylonitrile fiber non-woven fabric is 3mm, and the single-layer nano-polyacrylonitrile fiber non-woven fabric per square meter is coated with 35-45g activated carbon, and the nano-polyacrylonitrile fiber non-wove...

Embodiment 2

[0029] A filter material for air purification, which is a multi-layer composite structure, consisting of a central layer, a symmetrically arranged polyester fiber felt middle layer, and a stainless steel protective net outer layer. The thickness of the central layer is 32mm, and it is made of nano activated carbon particles The coated nano-polyacrylonitrile (PAN) fiber non-woven fabric layer is superimposed. The diameter of the nano-PAN fiber is 150-200 nanometers, the diameter of the nano-activated carbon particle is 40nm, the thickness of the middle layer of polyester fiber felt is 15mm, and the outer layer of stainless steel mesh For the protective layer, five layers of material are compressed and fixed by bolts. The thickness of the single-layer nano-polyacrylonitrile fiber non-woven fabric is 4mm, and the single-layer nano-polyacrylonitrile fiber non-woven fabric per square meter is coated with 35-45g activated carbon, and the nano-polyacrylonitrile fiber non-woven fabric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com