Machining device for proportional pressure control valve special for injection machine

A pressure control and processing device technology, applied in the direction of manufacturing tools, metal processing equipment, turning equipment, etc., can solve the problems of increased labor intensity, lengthened control valve processing time, scattered processing technology, etc., to reduce production input costs and shorten Good consistency of overall processing time and overall accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

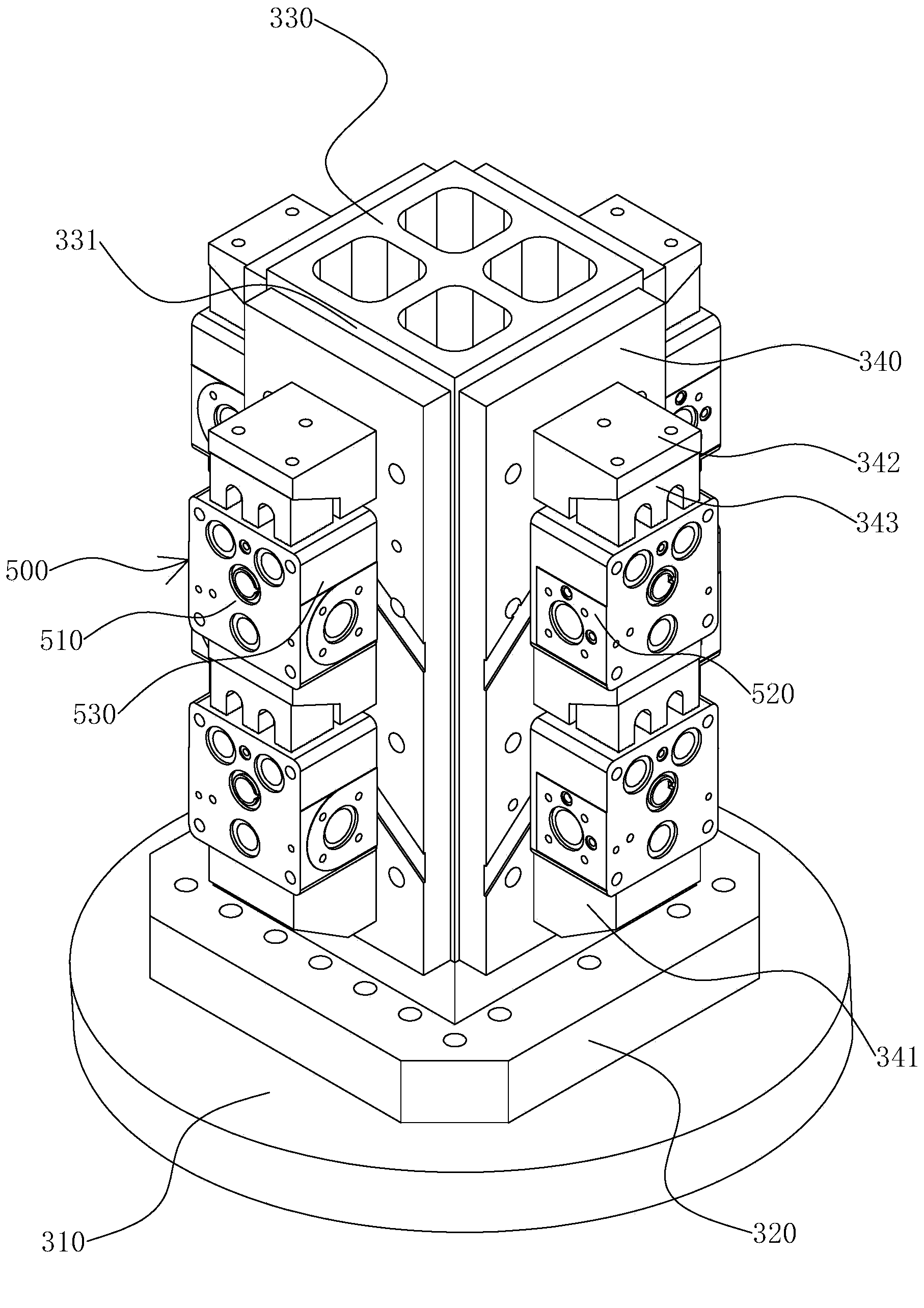

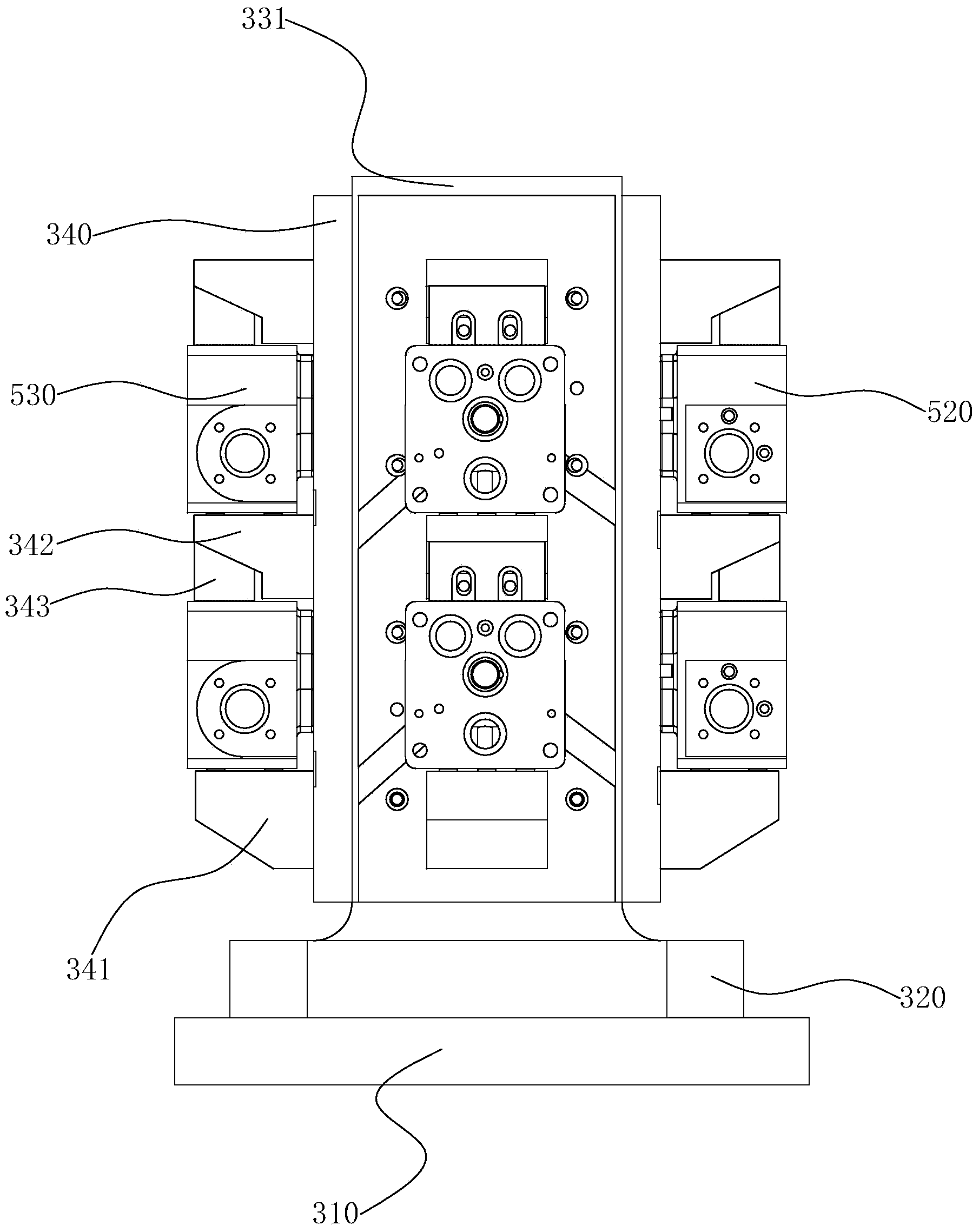

[0026] The control valve processed by this device is in the shape of a square block, which has six faces, of which face 1 and face 4 are two opposite end faces, face 2 and face 3 are opposite left and right faces, face 5 and face 3 are opposite Surface 6 is the opposite top surface and bottom surface, surface 1, surface 2 and surface 3 constitute the first group of processing surfaces, and surface 4, surface 5 and surface 6 constitute the second group of processing surfaces.

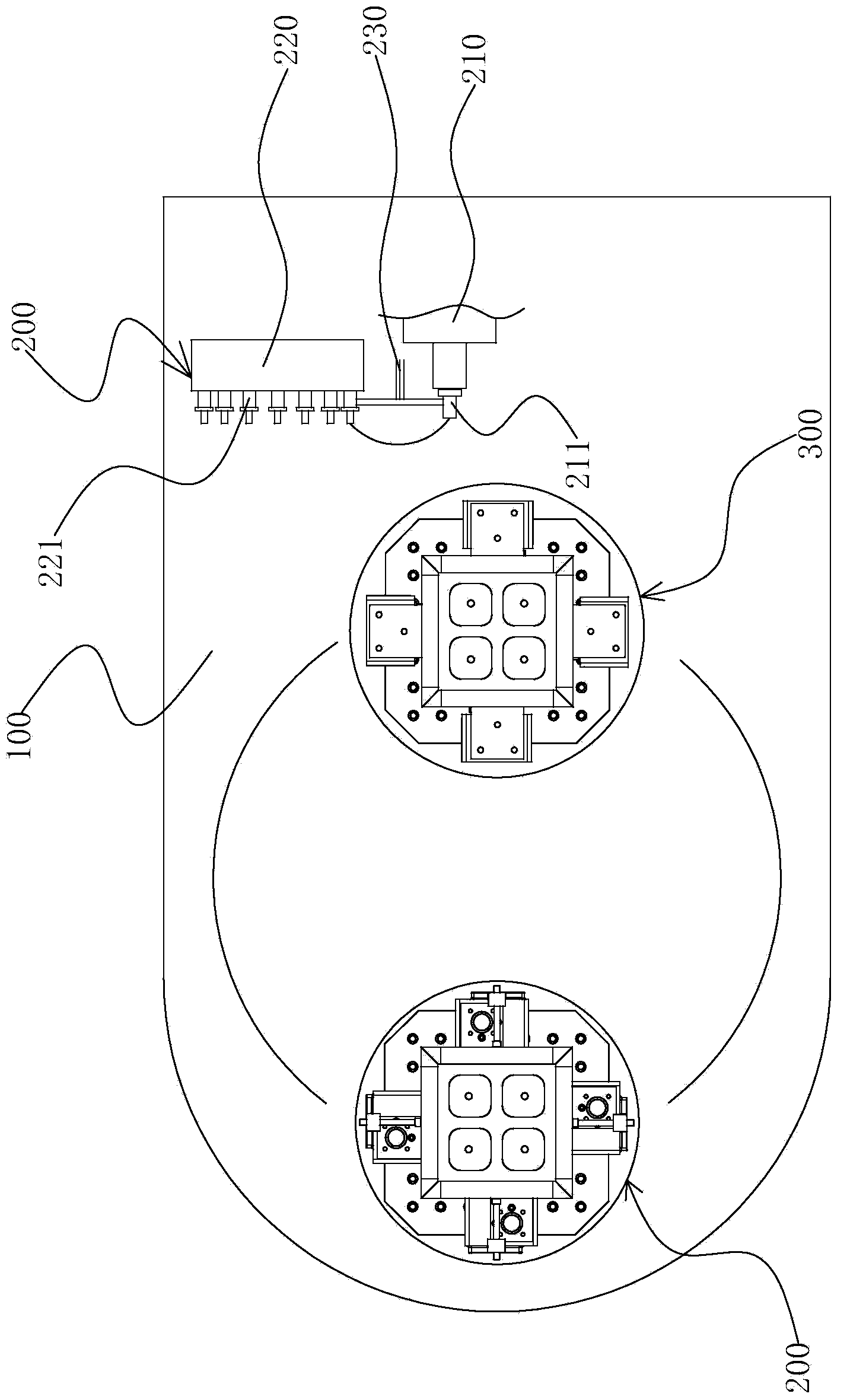

[0027] Such as figure 1 As shown, the present invention is a special proportional pressure control valve processing device for injection machines, which includes a fixed platform, a processing unit is arranged on the right side of the fixed platform,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com