Method for recovering methanol gas generated in Vc-Na methanol solution centrifuging process realized by using siphonic centrifuge

A siphon centrifuge, methanol solution technology, applied in organic chemistry, separation/purification of hydroxyl compounds, etc., can solve problems such as affecting air quality, methanol waste, confusion, etc., to reduce production costs, create economic benefits, and improve working environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

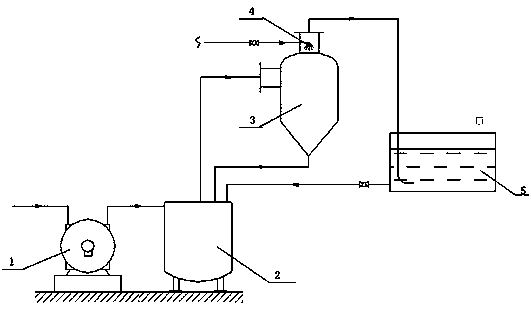

[0019] Such as figure 1 Shown, a kind of method that reclaims the methanol gas that siphon centrifuge produces when centrifugal Vc-Na methanol solution comprises the following steps:

[0020] Step 1: Block the part of the siphon centrifuge 1 that can leak methanol gas during the centrifugation process, and the methanol gas produced when centrifuging the Vc-Na methanol solution enters the mother liquor storage tank 2 together with the mother liquor, because part of the methanol gas in the centrifugation process It will be volatilized, and there will be a certain air pressure in the siphon centrifuge 1, so that methanol gas enters the gas-liquid separator 3 from the mother liquor storage tank 2, and a part of the methanol gas will become methanol droplets. Due to the different gas-liquid density and speed Methanol droplets in different dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com