Method for recovering useful ingredient from methane end gas containing iodine

A tail gas and methane technology, applied in separation methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of increasing methanol, increasing raw material consumption, environmental pollution, etc., to reduce emissions, save raw materials and energy, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

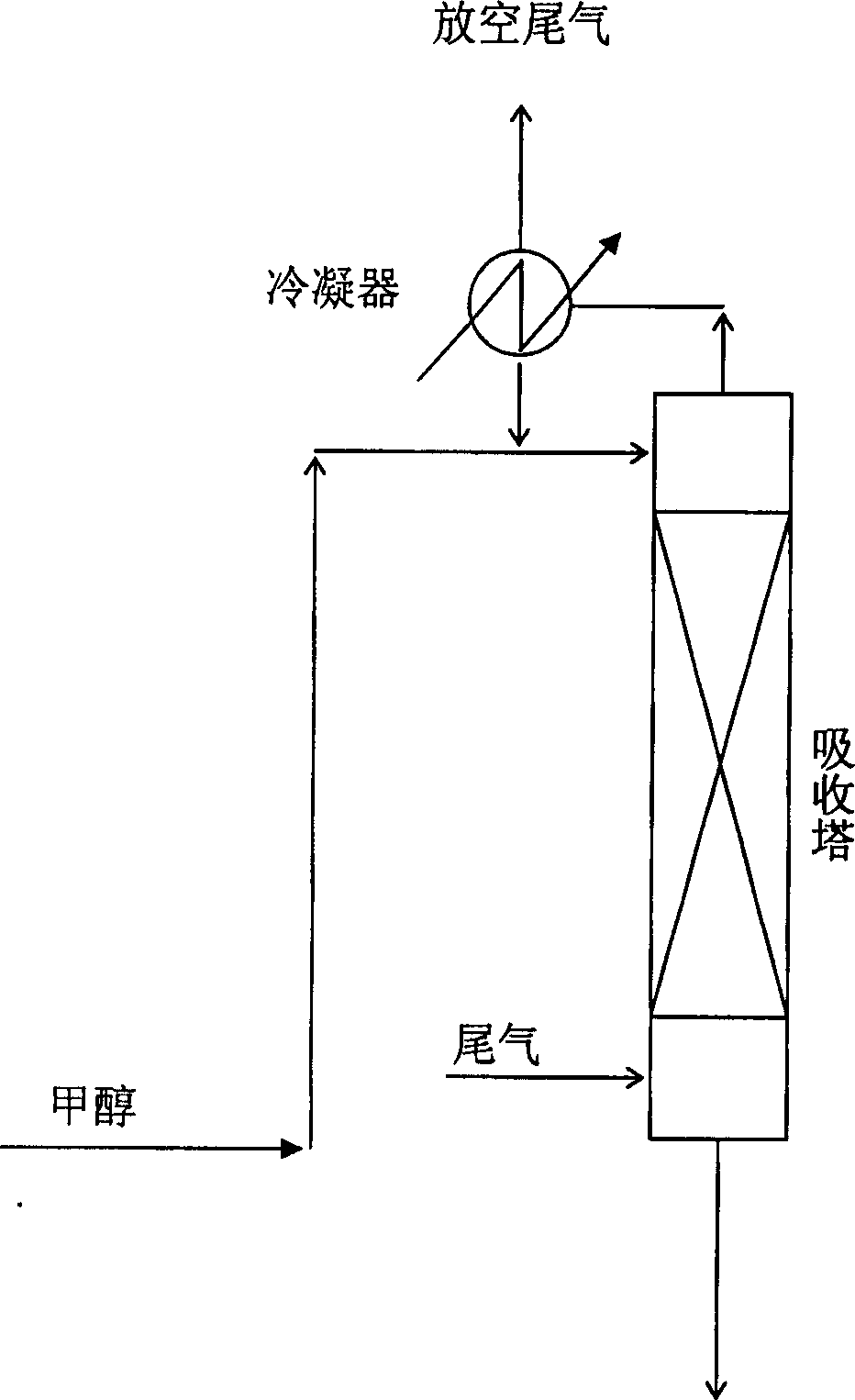

Method used

Image

Examples

Embodiment 1

[0011] Example 1 Low-pressure carbonylation of methanol to synthesize acetic acid Medium and high-pressure absorption tower absorbs with methanol at normal temperature

[0012] The tail gas entering the tower with a flow rate of 83kmol / h and a temperature of 50°C has a composition (V%, the same below) of CO 74.9%, CO 2 4.0%, H 2 11.6%, N 2 2.8%, CH 4 1.3%, CH 3 I 5.1% and trace amounts of methyl acetate, methanol, water, and acetic acid are absorbed by methanol with a flow rate of 85kmol / h and a temperature of 35°C. The pressure of the absorption tower is 2.85MPa, and the temperature of the tail gas exiting the tower is 35.7°C. Condensation to 15°C consumes energy 11.3kw, its composition is CO 80.0%, CO 2 3.0%, H 2 12.5%, N 2 3.0%, CH 4 1.4%, CH 3 I 0%, CH 3 OH<0.5%.

[0013] Comparative example 1 Chinese patent application CN15209204 medium and high pressure absorption tower absorbs with condensed methanol

[0014] The tail gas entering the tower with a flow...

Embodiment 2

[0018] Embodiment 2 Methanol low-pressure carbonylation synthesis acetic acid medium-low pressure absorption tower absorbs with methanol at normal temperature

[0019] The tail gas entering the tower with a flow rate of 30kmol / h and a temperature of 15°C is composed of CO 41.6%, CO 2 24.9%, H 2 6.1%, N 2 5.5%, CH 4 0.7%, CH 3 I 20.1%, methyl acetate 0.8%, and trace amounts of methanol, water, and acetic acid are absorbed by methanol with a flow rate of 120kmol / h and a temperature of 25°C. The pressure of the absorption tower is 0.25MPa, and the temperature of the tail gas exiting the tower is 26.0°C. Condensate to -15°C , energy consumption 27.71kw, its composition is CO 53.8%, CO 2 29.6%, H 2 7.9%, N 2 7.2%, CH 4 0.9%, CH 3 I 0%, CH 3 OH 0.7%.

Embodiment 3

[0022] Example 3 In the process of carbonylation to synthesize acetic anhydride, the tail gas purification tower is absorbed by methanol at normal temperature

[0023] The tail gas entering the tower with a flow rate of 120kmol / h and a temperature of 15°C is composed of CO 52.7%, CO 2 31.6%, H 2 7.8%, N 2 7.0%, CH 4 0.9%, and a small amount of methyl iodide and methyl acetate, absorbed by methanol with a flow rate of 120kmol / h and a temperature of 25°C, the pressure of the absorption tower is 0.25MPa, the temperature of the exhaust gas exiting the tower is 19.1°C, condensed to -15°C, and the energy consumption is 100.57kw , its composition is CO 52.9%, CO 2 30.7%, H 2 7.8%, N 2 7.0%, CH 4 0.9%, CH 3 I 0%, CH 3 OH 0.7%.

[0024] No condensation process in the process of comparative example 4 embodiment 3

[0025] The tail gas entering the tower with a flow rate of 120kmol / h and a temperature of 15°C is composed of CO 52.7%, CO 2 31.6%, H 27.8%, N 2 7.0%, C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com