Tobacco flavor and preparation method thereof

A tobacco flavoring and enzymatic hydrolysis technology, applied in the field of tobacco, to achieve the effects of good flavor, high efficiency, rich sugar components and amino acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

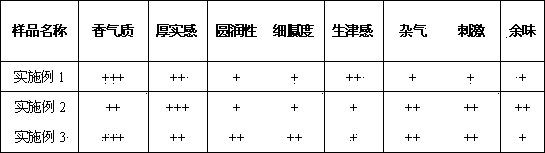

Examples

Embodiment 1

[0041] (1) First, carry out enzymatic hydrolysis and secondary extraction of the compound Chinese herbal medicine powder: mix 40 grams of Asparagus asparagus, 40 grams of Ophiopogon japonicus, 15 grams of Poria cocos and 5 grams of Maodongqing Chinese herbal medicine powder (particle size <100 mesh) and mix them with 500 grams of water Add it into the extraction container, and put it in an ultrasonic environment for 10 minutes at room temperature. Then carry out the first step of enzymatic hydrolysis, the enzyme used is a compound enzyme combined with cellulase and pectinase, the weight ratio of cellulase and pectinase is 8:1, the enzymolysis temperature is 50°C, and the pH of the solution is adjusted with citric acid value to 3.5, the enzymolysis time is 5 hours, and the enzyme dosage is 2‰ of the weight of the compound Chinese herbal medicine powder; the enzyme used in the second step of enzymolysis is α-amylase, the enzymolysis temperature is 65°C, and the pH value of the so...

Embodiment 2

[0047] (1) First, carry out enzymatic hydrolysis and secondary extraction of the compound Chinese herbal medicine powder: mix 50 grams of Asparagus asparagus, 25 grams of Ophiopogon japonicus, 18 grams of Poria cocos and 7 grams of Maodongqing Chinese herbal medicine powder (particle size <100 mesh) and mix them with 1000 grams of water Add it into the extraction container, and put it in an ultrasonic environment for 20 minutes at room temperature. Then carry out the first step of enzymatic hydrolysis, the enzyme used is a compound enzyme combining cellulase and pectinase, the weight ratio of cellulase and pectinase is 6:1, the enzymolysis temperature is 55°C, and the pH of the solution is adjusted with citric acid value to 4, the enzymolysis time is 1 hour, and the enzyme dosage is 5‰ of the weight of the compound Chinese herbal medicine powder; the enzyme used in the second step of enzymolysis is α-amylase, the enzymolysis temperature is 80°C, and the pH value of the solution...

Embodiment 3

[0053] (1) First, carry out enzymatic hydrolysis and secondary extraction of the compound Chinese herbal medicine powder: mix 60 grams of Asparagus asparagus, 20 grams of Ophiopogon japonicus, 20 grams of Poria cocos and 10 grams of Maodongqing Chinese herbal medicine powder (particle size <100 mesh) and mix them with 800 grams of water Add it to the extraction container, and put it in an ultrasonic environment for 15 minutes at room temperature. Then carry out the first step of enzymatic hydrolysis, the enzyme used is a compound enzyme combining cellulase and pectinase, the weight ratio of cellulase and pectinase is 10:1, the enzymolysis temperature is 53°C, and the pH of the solution is adjusted with citric acid value to 4, the enzymolysis time is 3 hours, and the enzyme dosage is 1.5‰ of the weight of the compound Chinese herbal medicine powder; the enzyme used in the second step of enzymolysis is α-amylase, the enzymolysis temperature is 70°C, and the pH value of the soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com