Method for preparing maotai-flavor liquor by employing primary and secondary pits in fermentation manner

The technology of Maotai-flavor liquor and mother cellar is applied in the field of liquor production, which can solve the problems of increasing production cost and large material loss, and achieves the effects of reducing material loss, improving output and quality, and ensuring flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

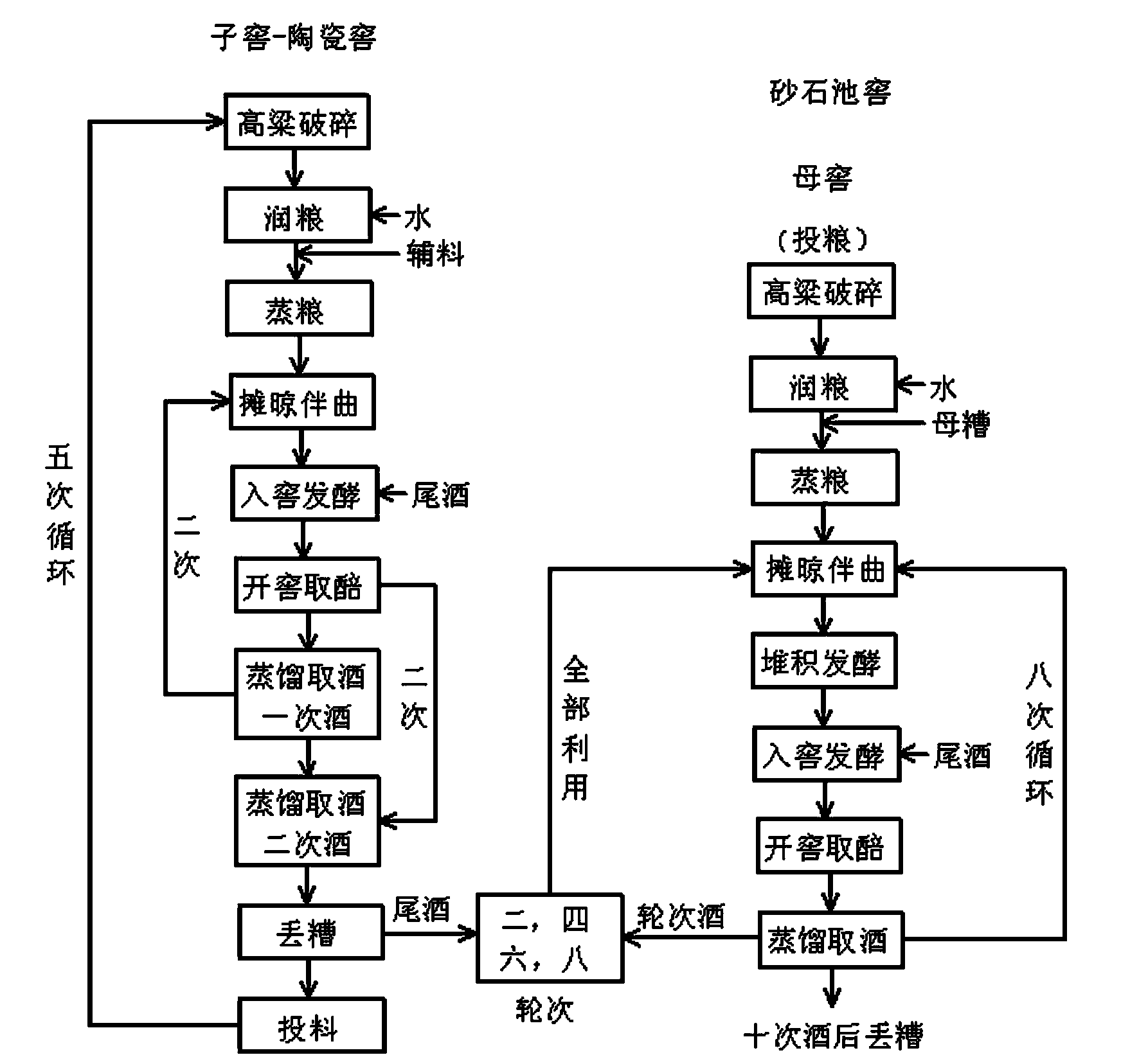

[0017] A method for fermenting Maotai-flavor liquor in a mother-child cellar according to the present invention, the specific implementation mode will be explained as follows: it has changed the traditional single sandstone mud cellar, and used ceramic containers as a supporting cellar. It is called the sub-pit, and the gravel mud pit is called the mother cellar. The volume of the sub-cellar is 1 / 10 of the volume of the mother cellar, and the volume of the mother cellar is 10 times larger than that of the child cellar. This volume ratio is used for supporting fermentation. Multiple sub-cellars are arranged in a row, and the mother cellars are also arranged in a row. The distance between the rows of sub-cellars and mother cellars is set to 1.8-2.0 meters, and the mouths of the sub-cellars and mother cellars are flush with the ground; And there is an open space in the factory building as a drying hall, and its area is 5-10 times that of the mother cellar.

[0018] The method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com