Measurement system and measurement method for secondary electron emission coefficient of medium film

A technology of secondary electron emission and dielectric thin film, applied in the field of electronic science, can solve the problems of complex measurement method, high cost, complex measurement device, etc., and achieve the effect of simple measurement method, low cost, and elimination of positive charges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

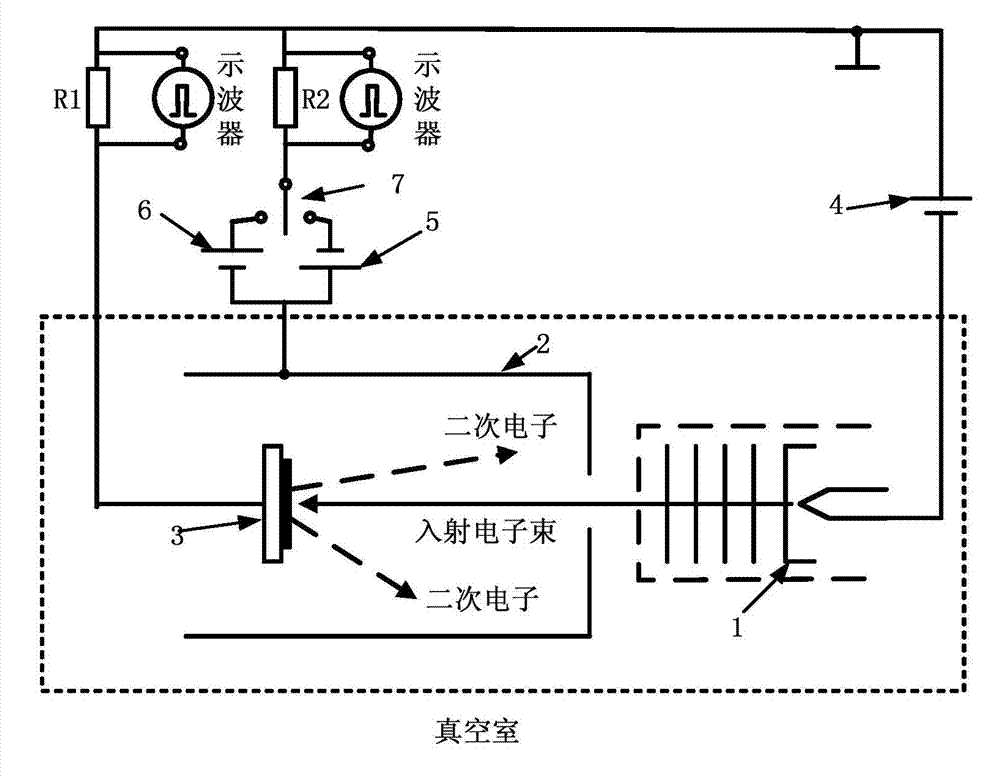

[0030] like figure 1 As shown, the present invention provides a measurement system for the secondary electron emission coefficient of a dielectric thin film, comprising: an electron gun 1, a barrel-shaped collector 2, a sample holder 3, and a total power supply 4, wherein the electron gun 1, the barrel-shaped collector 2. The sample holder 3 is set in a vacuum chamber, the vacuum degree of the vacuum chamber is high vacuum, and the vacuum pressure of the vacuum chamber is less than 3×10-3Pa; the total power supply 4 is a DC high voltage stabilized power supply. The top of the barrel-shaped collector 2 in the vacuum chamber is provided with a round hole, the sample holder 3 is arranged in the barrel-shaped collector 2, the electron gun 1 is arranged outside the barrel-shaped collector 2, the sample holder 3, the round hole, and the emitting end of the electron gun 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com