Specimen size design method for ultrasonic and tension-compression fatigue test of iron-based powder metallurgical material

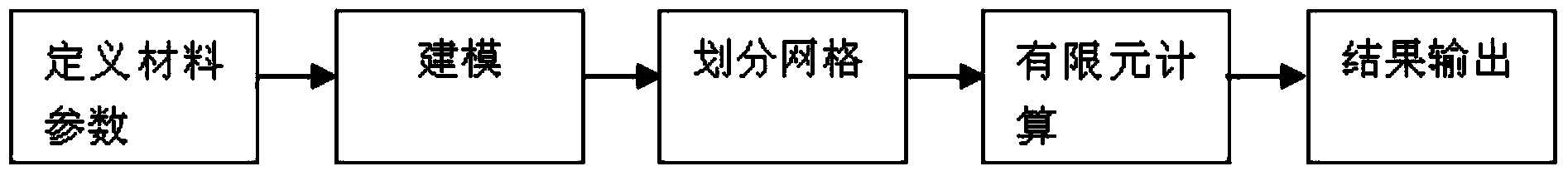

An iron-based powder metallurgy and fatigue experiment technology, applied in calculation, special data processing applications, instruments, etc., can solve the lack of methods for testing ultra-high cycle tension and compression fatigue performance, lack of rapid design methods for ultrasonic tension and compression fatigue dimensions, and materials Tension and compression fatigue simulation test and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

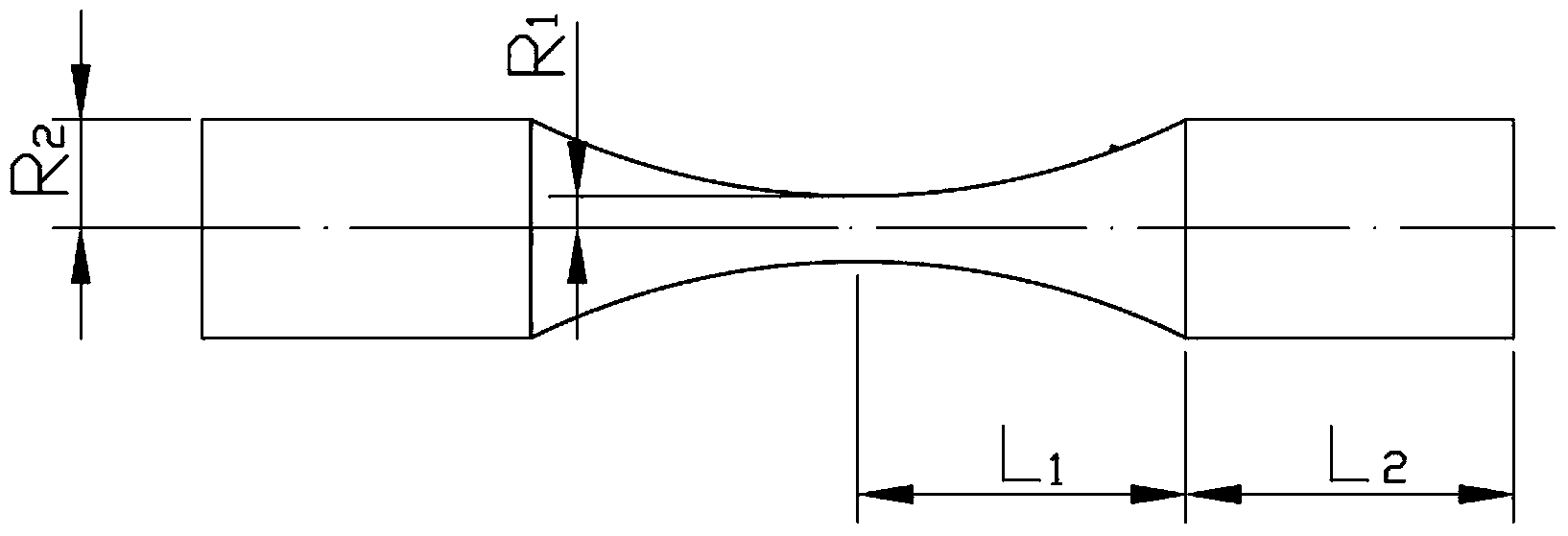

[0050] Mix Fe, Cu, Ni and Mo powders evenly, carry out partial pre-diffusion treatment at 830°C, mix in 1% graphite and 0.1% lubricant, carry out mold wall lubrication and pressing at 120°C, and the pressing pressure is 650MPa. Afterwards, mesh belt sintering was carried out at 1120°C for 1 hour to obtain an iron-based warm-pressed Fe-Cu-Ni-Mo-C powder metallurgy material, and the measured material density was 7.31g / cm 3 , the tensile strength is 776MPa, and the modulus of elasticity is 156GPa. Then the sample size is calculated, and the shape of the axial tension and compression sample is preset as a dumbbell, such as figure 1 shown. Among them, the calculation of the dumbbell-shaped axial tension-compression specimen is carried out, and the specific process is as follows:

[0051] 1) Draw up R first 1 , R 2 , L 1 data, R 1 is the radius of the thinnest point in the middle of the sample, R 2 is the radius of the cylinder at both ends of the sample, L 1 is half the len...

Embodiment 2

[0084] Mix Fe, Cu, and Mn powders evenly, first perform pre-diffusion treatment at 830°C, then mix in 1% graphite and 0.1% lubricant, and carry out mold wall lubrication and pressing at 120°C with a pressing pressure of 700MPa. Afterwards, mesh belt sintering at 1120°C for 1 hour was carried out to obtain an iron-based warm-pressed Fe-Cu-Mn-C powder metallurgy material. In this example, the measured material density was 7.32g / cm 3 , the tensile strength is 709MPa, and the modulus of elasticity is 146GPa.

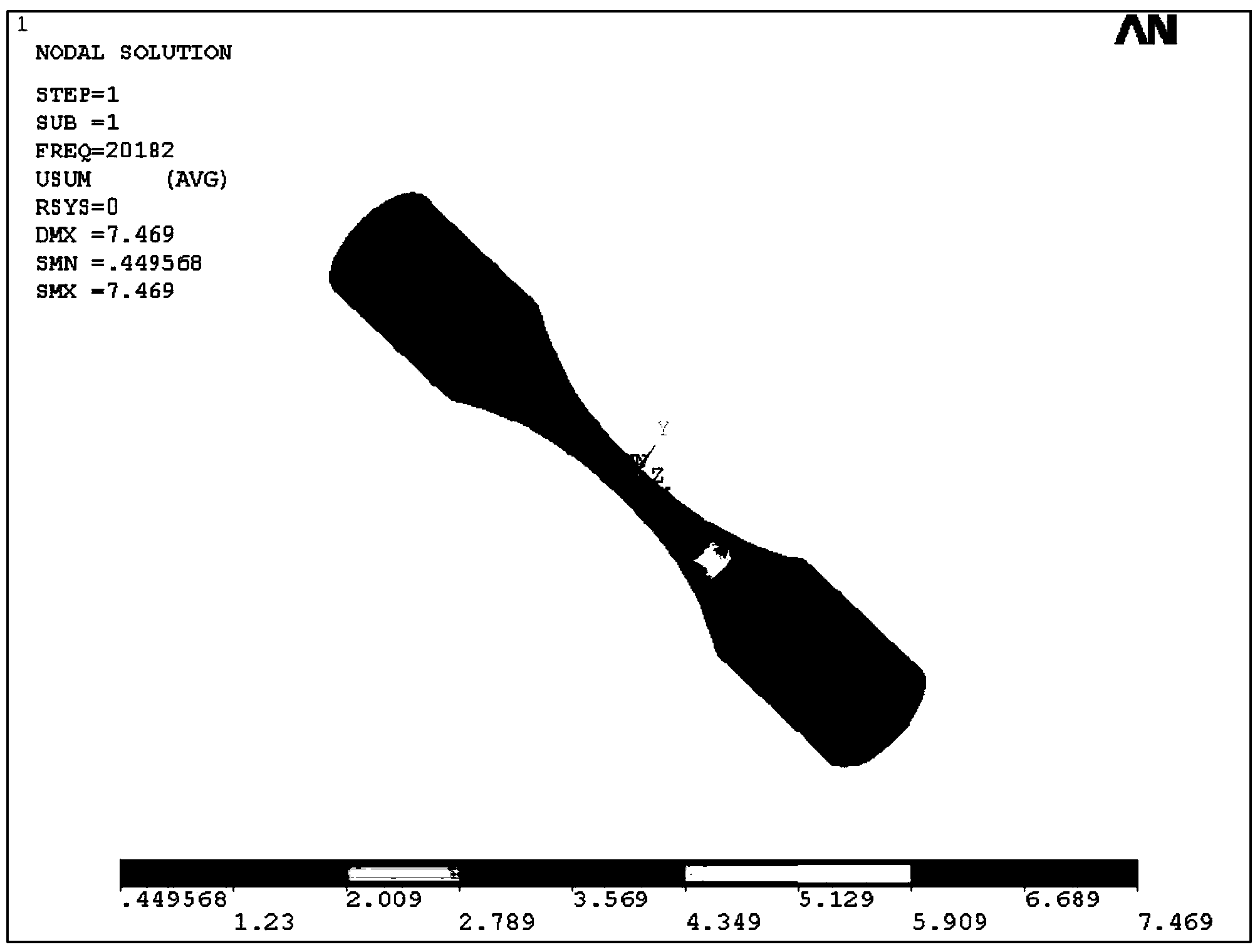

[0085] The shape of the pre-set axial tension and compression specimen is dumbbell-shaped, similarly, first set R 1 =1.5mm, R 2 =5mm, L 1 =14mm, then calculate the size of the sample (the calculation process of this embodiment is the same as that of embodiment 1), and obtain the resonance length L 2 =12.2mm. Similarly, after getting R 1 , R 2 , L 1 and L 2After obtaining the data, the size of the axial tension-compression sample is used as the boundary condition to m...

Embodiment 3

[0088] Mix Fe, Cu, Ni and Mo powders evenly, perform partial pre-diffusion treatment at 830°C, mix in 1% graphite and 0.1% lubricant, and press at room temperature with a pressing pressure of 500MPa. Afterwards, mesh belt sintering at 1120°C for 1 hour was carried out to obtain an iron-based warm-pressed Fe-Cu-Mn-C powder metallurgy material. In this example, the measured material density was 6.91g / cm 3 , the tensile strength is 510MPa, and the modulus of elasticity is 120GPa.

[0089] The shape of the preset axial tension and compression specimen is dumbbell-shaped, and R 1 =1.75mm, R 2 =5mm, L 1 =16mm, then calculate the size of the sample (the calculation process of this embodiment is the same as that of embodiment 1), and obtain the resonance length L 2 =11mm. Similarly, after getting R 1 , R 2 , L 1 and L 2 After obtaining the data, the size of the axial tension and compression sample was used as the boundary condition to model, and the Ansys finite element modal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com