Ceramic material and spraying method for preventing corona discharge and pollution flashover on the surface of high-voltage lines

A technology of corona discharge and ceramic materials, which is applied in the direction of metal material coating process, ceramics, coatings, etc., can solve problems such as corona discharge, achieve high insulation, good surface wettability, prevent corona discharge and The effect of pollution flashover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1, weighing according to mass percentage: rutile phase TiO with a particle size of 30-50 μm 2 28%, anatase phase TiO with a particle size of 30-50 μm 2 71%, auxiliary material Y 2 o 3 1%, the sum of the mass percentages of the above components is 100%, use a mechanical powder mixer to mix the above-mentioned weighed components evenly to obtain ceramic material powder;

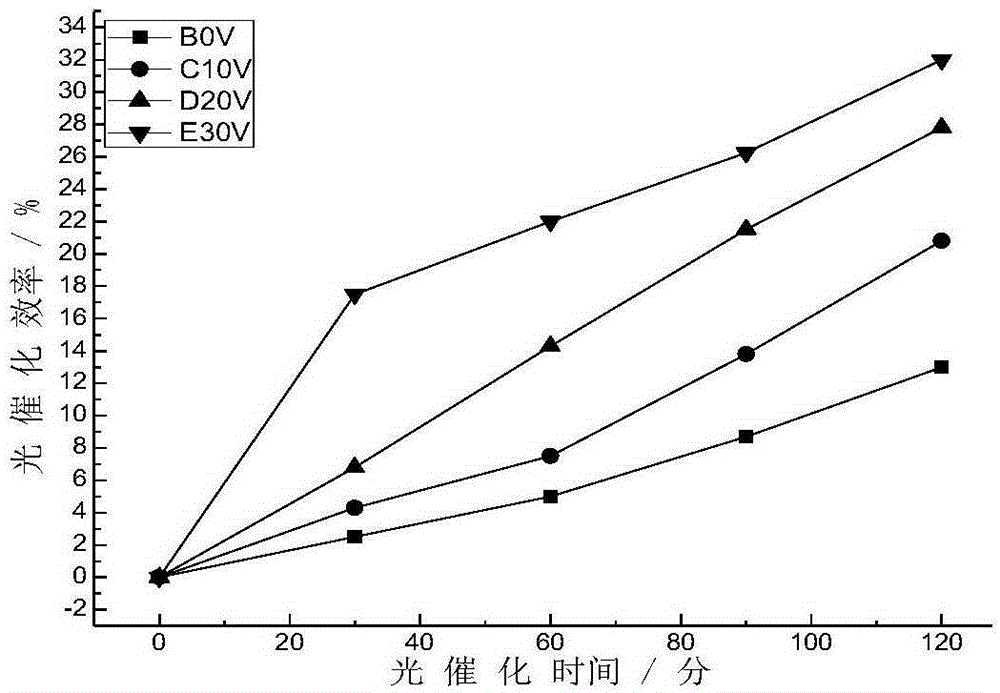

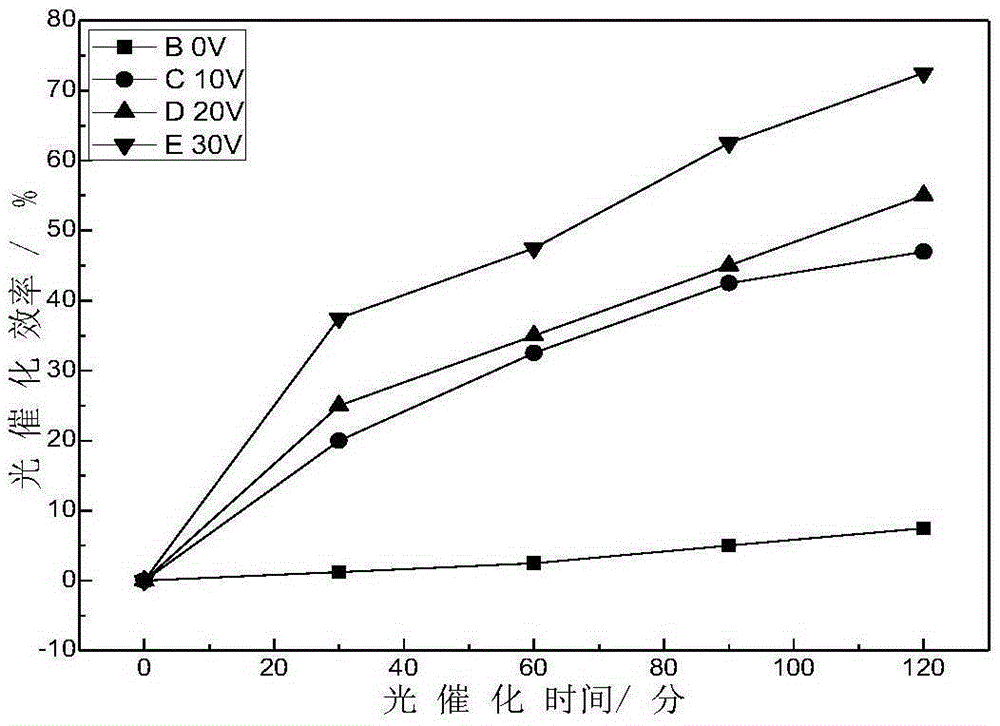

[0032] Step 2, use diamond sand with a particle size of 35 μm to sandblast the surface of the aluminum transmission line LGJ150 / 20, the pressure of the sandblasting is 0.4MPa, and then use the atmospheric plasma spraying method to pass the ceramic material powder prepared in step 1 through powder feeding Before the device is delivered to the gun nozzle of the plasma spraying equipment, the process parameters of the plasma spraying equipment are controlled: hydrogen pressure 0.20Mpa, argon pressure 0.6Mpa, voltage 55V, current 500A, spraying distance 200mm; After the surface-treated wire surface i...

Embodiment 2

[0034] Step 1, weighing according to mass percentage: rutile phase TiO with a particle size of 30-50 μm 2 48%, anatase phase TiO with a particle size of 30-50 μm 2 51%, auxiliary material Y 2 o 3 1%, the sum of the mass percentages of the above components is 100%, use a mechanical powder mixer to mix the above-mentioned weighed components evenly to obtain ceramic material powder;

[0035]Step 2, use diamond sand with a particle size of 45 μm to sandblast the surface of the aluminum transmission line, the pressure of the sandblasting is 0.45MPa, and then use the atmospheric plasma spraying method to transport the ceramic material powder prepared in step 1 to the In front of the gun nozzle of the plasma spraying equipment, control the process parameters of the plasma spraying equipment: hydrogen pressure 0.25Mpa, argon pressure 0.70Mpa, voltage 60V, current 550A, spraying distance 220mm; the plasma spraying equipment is instantly heated and atomized and sprayed to the surface ...

Embodiment 3

[0037] Step 1, weighing according to mass percentage: rutile phase TiO with a particle size of 30-50 μm 2 71%, anatase phase TiO with a particle size of 30-50 μm 2 28%, auxiliary material Y 2 o 3 1%, the sum of the mass percentages of the above components is 100%, use a mechanical powder mixer to mix the above-mentioned weighed components evenly to obtain ceramic material powder;

[0038] Step 2, use diamond sand with a particle size of 55 μm to sandblast the surface of the aluminum transmission line, the pressure of the sandblasting is 0.5MPa, and then use the atmospheric plasma spraying method to transport the ceramic material powder prepared in step 1 to the In front of the nozzle of the plasma spraying equipment, control the process parameters of the plasma spraying equipment: hydrogen pressure 0.30Mpa, argon pressure 0.75Mpa, voltage 70V, current 600A, spraying distance 250mm; the plasma spraying equipment is instantly heated and atomized and sprayed to the surface trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com