TFT, TFT array substrate, manufacturing method of TFT array substrate and display device

A technology of thin film transistors and array substrates, applied in the field of display devices, can solve problems such as breakdown of gate insulating layers, and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

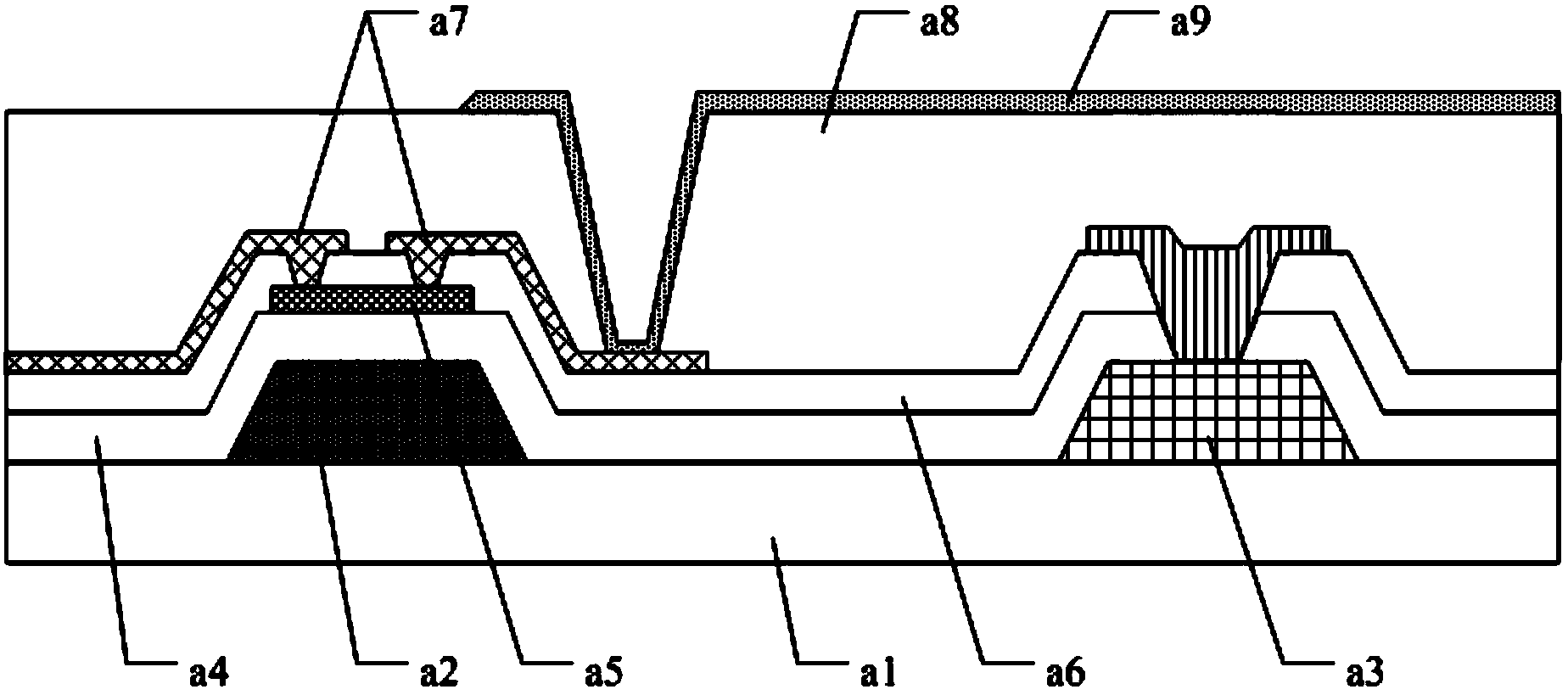

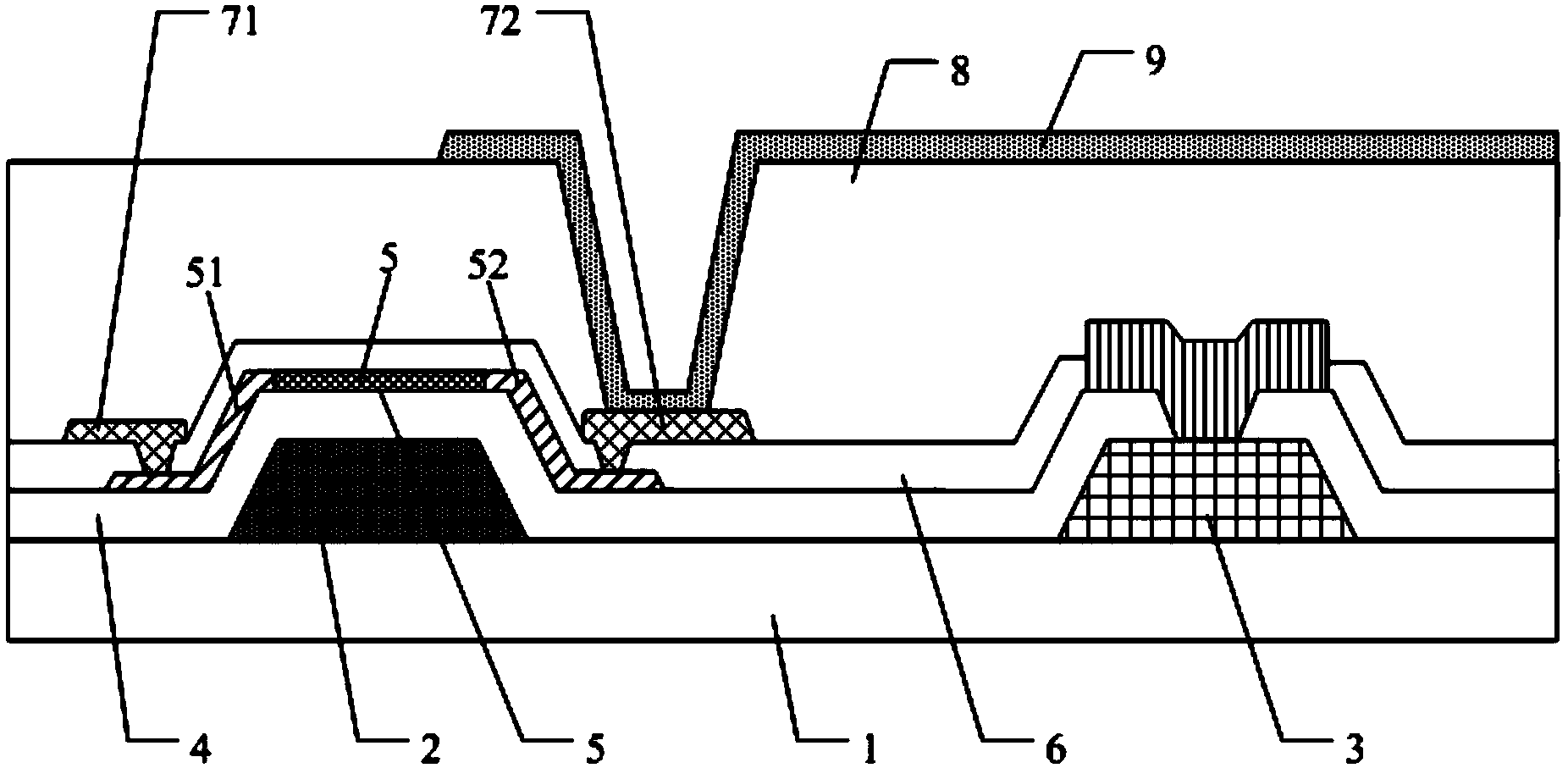

[0142] Embodiment 1. The manufacturing method of the TFT array substrate provided in this embodiment includes the following steps:

[0143] 1) Using a standard method to clean the transparent substrate substrate 1;

[0144] 2) Preparation of the gate electrode 2 and the lower electrode 3 of the storage capacitor, that is, using sputtering (sputter) or evaporation method to deposit a metal film with a thickness of 50 nm to 400 nm on the substrate, and perform patterning treatment to form a gate electrode 2 and the graph of the lower electrode 3 of the storage capacitor;

[0145] 3) Using plasma enhanced chemical vapor deposition (Plasma Enhanced Chemical Vapor Deposition, PECVD), deposit a SiOx film with a thickness of 100 nm to 500 nm on the substrate after the above steps to form the gate insulating layer 4;

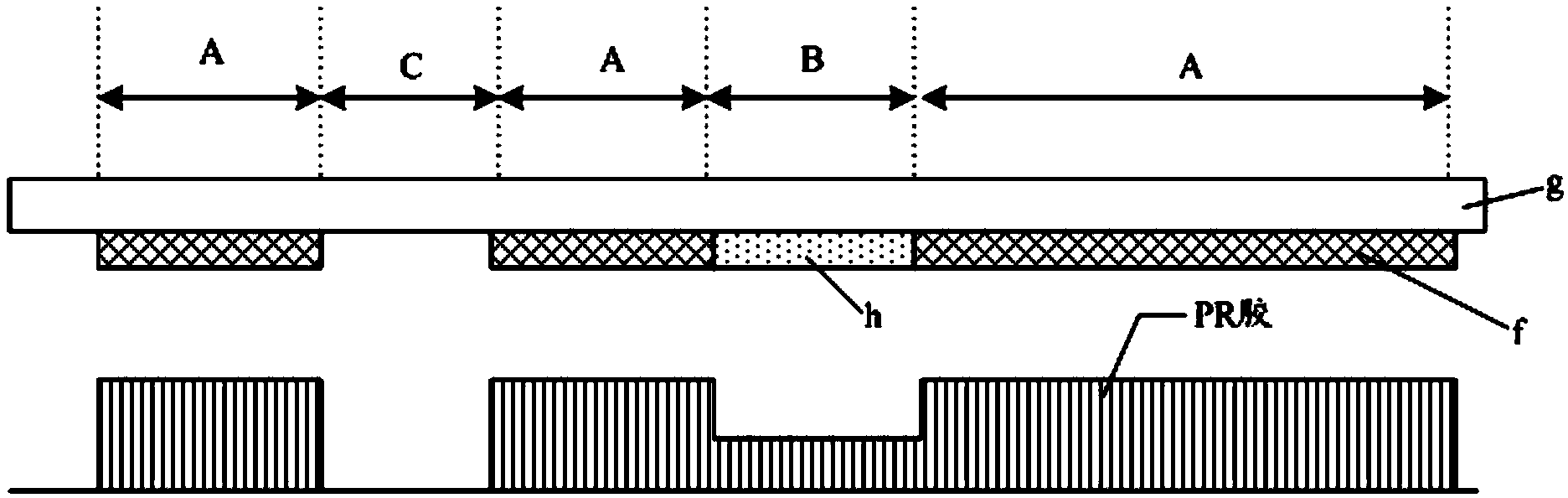

[0146] 4) Deposit an IGZO thin film with a thickness of 10 nm to 80 nm on the base substrate that has completed the above steps by using the sputter method, and perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com