A kind of sugarcane fiber feed prepared with sugarcane as raw material

A sugarcane fiber and sugarcane technology, applied in the field of animal feed, can solve the problems of high sugarcane cost, undiscovered, low feeding value, etc., and achieve the effects of low drying energy consumption, preventing feed mildew, and saving transportation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

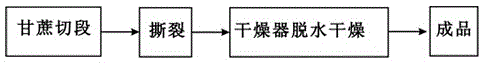

[0086] Embodiment one: the whole plant fresh sugarcane with natural moisture content after harvesting is about 60-70% is cut into 8-10cm long sugarcane segments, weighed, according to the processing requirements of the dryer to determine the amount of sugarcane processed in each batch, the The weighed sugarcane segments are torn into sugarcane fibers, and then the sugarcane fibers are transported to the drum dryer, and the sugarcane fibers are dehydrated and dried with hot flue gas at 450-500°C to obtain high-energy sugarcane fiber feed with a moisture content of 10-12%. , that is, the finished product, after being compressed, bundled, packaged and packaged, it is stored for dispatch.

Embodiment 2

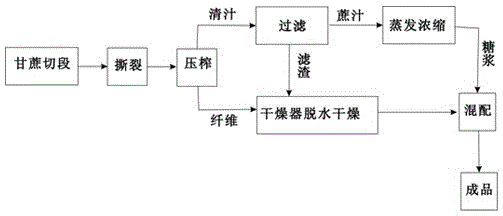

[0087] Embodiment two: the whole plant fresh sugarcane with natural water content after harvesting is about 60-70% is cut into 6-8cm long sugarcane section, weighs, according to the processing requirement of drier to determine the sugarcane amount of each batch of processing, will The weighed sugarcane segments are torn into sugarcane fibers and pressed to obtain clear juice with a water content of 47-55% sugarcane fibers and a sugar content of 18-20%. The hot flue gas dehydrates and dries the sugarcane fiber to obtain sugarcane fiber with a water content of 3-5%; the clear juice with a sugar content of 18-20% is filtered, and the filter residue is returned to the dryer for drying, and the filtered sugarcane juice is evaporated and concentrated , to obtain a syrup with a concentration of 80%; the syrup is evenly sprayed into the dried sugarcane fiber material, fully stirred and mixed to obtain a high-energy sugarcane fiber feed with a water content of 10-12%, that is, the finis...

Embodiment 3

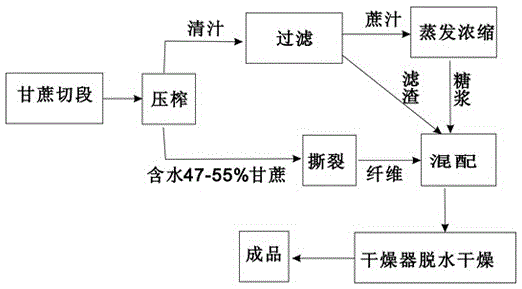

[0088] Embodiment 3: cut the whole plant fresh sugarcane after harvesting into 8-12cm long sugarcane segments, weigh them, determine the amount of sugarcane processed in each batch according to the processing requirements of the drier, squeeze the weighed sugarcane segments, Sugarcane and clear juice with a water content of 47-55% are obtained, the clear juice is filtered, the filter residue is returned to the dryer for drying, and the filtered cane juice is evaporated and concentrated to obtain a syrup with a concentration of 80%; the sugarcane with a water content of 47-55% is torn Crack it into sugarcane fiber, mix it fully with 80% syrup, send it to the dryer, dehydrate and dry it with hot flue gas at 450-500°C, and obtain high-energy sugarcane fiber feed with a moisture content of 10-12%, that is, the finished product.

[0089] The harvesting of the sugarcane in the present invention can be more than 5-10cm away from the root, and such residual amount can reduce the pollutan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com