Preparation method of tobacco extract and application of tobacco extract in cigarettes

A technology of tobacco extract and tobacco, which is applied in the fields of tobacco, application, and treatment of tobacco, can solve the problems of large solvent consumption, average quality of tobacco paste, and residue, and achieve high repeatability, high application value, and method simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Weigh 200g of pieces of tobacco leaf (C2F) into a container, add 2000g of 70% ethanol, then add 1g of phosphoric acid, heat with an electric heating mantle and extract at 90°C for 2 hours. The obtained product was filtered and cooled to 20° C., left to stand for 1 hour, and the supernatant was concentrated under reduced pressure to a paste. The relative density of the paste was 1.258, and 110 g of tobacco extract was obtained.

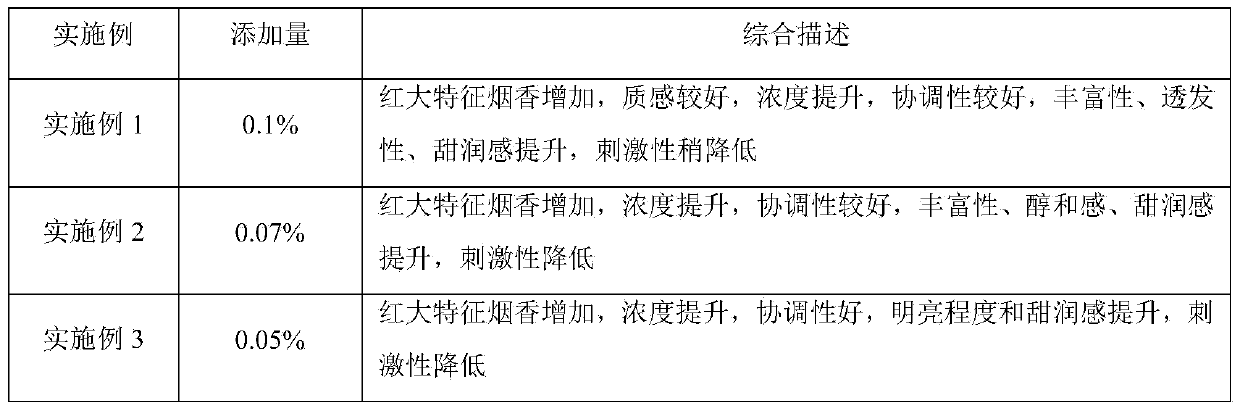

[0014] Tobacco extract was added to tobacco leaves (X3F) at a mass ratio of 0.1%, and the sensory evaluation results are shown in Table 1.

Embodiment 2

[0016] Weigh 1000g of pieces of tobacco leaf (C2F) into a round bottom flask, add 7000g of 90% ethanol, then add 15g of sulfuric acid, heat with an electric heating mantle and extract at 80°C for 1 hour. The obtained product was filtered and then cooled to 25°C, left to stand for 1.5 hours, and the supernatant was concentrated under reduced pressure to a paste with a relative density of 1.245 to obtain 548 g of tobacco extract.

[0017] Tobacco extract was added to tobacco leaves (X3F) at a mass ratio of 0.07%, and the sensory evaluation results are shown in Table 1.

Embodiment 3

[0019] Weigh 2000g of pieces of tobacco leaf (C2F) into a container, add 10000g of 95% ethanol, and then add 60g of phosphoric acid, heat with an electric heating mantle and extract at 60°C for 3 hours. The obtained product was filtered and cooled to 28°C, and left to stand for 2 hours. The supernatant was concentrated under reduced pressure to a paste. The relative density of the paste was 1.255, and 1162 g of tobacco extract was obtained.

[0020] Tobacco extract was added to tobacco leaves (X3F) at a mass ratio of 0.05%, and the sensory evaluation results are shown in Table 1.

[0021] Table 1 The sensory evaluation results of tobacco extracts with different treatment methods and addition amounts on the red tabaco leaves (X3F)

[0022] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com