Meso-porous silicon mudpack, preparation method and application method thereof

A technology of mesoporous silicon and mud film, applied in the field of skin care products, can solve the problems of dry skin and increased wrinkles, and achieve the effects of fine texture, reduced wrinkles and good moisturizing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

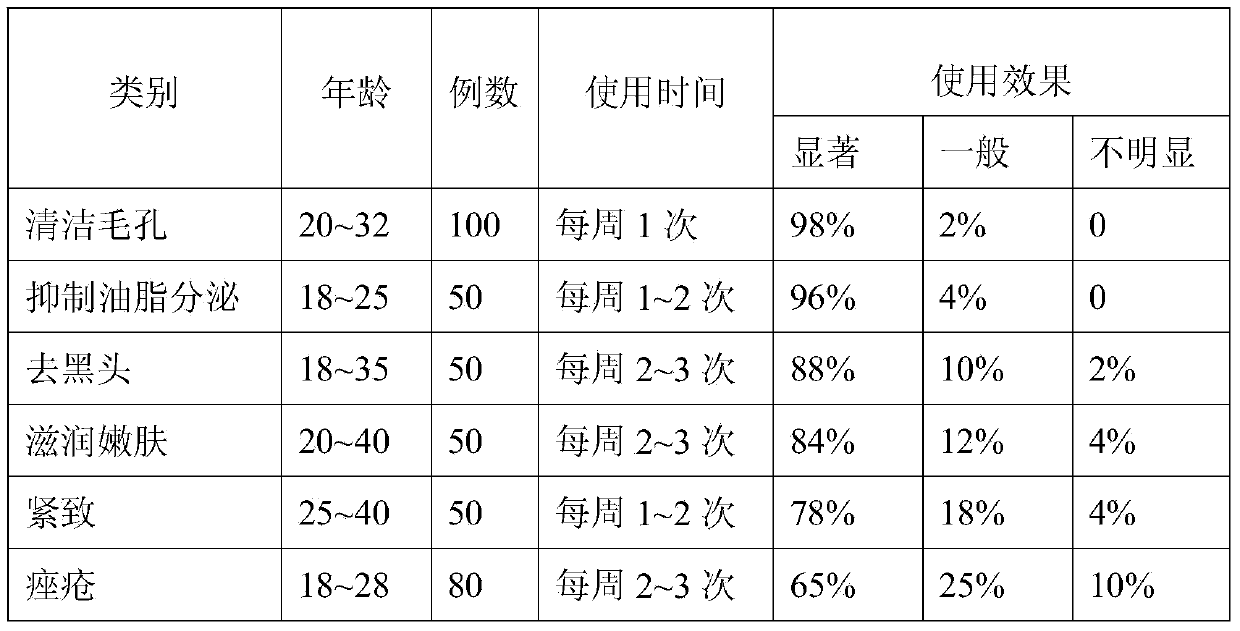

Image

Examples

Embodiment example 1

[0022] (1) 16g of kaolin, 6g of talc, 1.3g of titanium dioxide, and 25g of mesoporous silica were weighed and mixed according to mass percentage, sterilized at 115±5°C for 50 minutes, and cooled to room temperature. Add 10 g of squalane and 5 g of deionized water to magnetically stir at a speed of 200 rpm, mix them uniformly, and prepare a powdery raw material mixture for use.

[0023] (2) Mix 8 g of jojoba oil, 4 g of avocado oil, and 6 g of sweet almond oil in a mass ratio, heat to 75°C, and perform magnetic stirring and dissolution at a speed of 200 rpm to obtain an oil phase.

[0024] (3) Heat 16 g of deionized water and 2 g of aloe extract to 75°C, and perform magnetic stirring and dissolution at a speed of 200 rpm to obtain an aqueous phase;

[0025] (4) Mix the heated oil phase with the water phase, keep the temperature at 75°C, and emulsify it with magnetic stirring at a rotating speed of 300 rpm for 10 minutes to drive away all bubbles.

[0026] (5) After cooling to 40°C, add...

Embodiment example 2

[0029] (1) 10g of kaolin, 4g of talc, 0.2g of titanium dioxide, and 20g of mesoporous silica are respectively weighed and mixed by mass percentage, sterilized at 115±5°C for 50 minutes, and cooled to room temperature. Add 8 g of squalane and 8 g of deionized water to magnetically stir at 250 rpm and mix them uniformly to prepare a powdery raw material mixture for use.

[0030] (2) Mix 12 g of jojoba oil, 6 g of avocado oil, and 9 g of sweet almond oil in a mass ratio, heat to 80°C, and perform magnetic stirring and dissolution at a speed of 250 rpm to obtain an oil phase.

[0031] (3) Heat 18.5 deionized water and 4g aloe extract to 80°C, magnetically stir and dissolve at 250rpm to obtain the water phase;

[0032] (4) Mix the heated oil phase and water phase, keep the temperature at 80°C, and perform emulsification at 400 rpm magnetic stirring for 15 minutes to drive away all bubbles.

[0033] (5) After cooling to 45°C, add the powdery raw material mixture prepared in (1), 0.2g flavor...

Embodiment example 3

[0036] (1) 13g of kaolin, 5g of talc, 1g of titanium dioxide, and 22.5g of mesoporous silica were weighed and mixed according to mass percentages, sterilized at 115±5°C for 50 minutes, and cooled to room temperature. Add 9 g of squalane and 6.5 g of deionized water and magnetically stir at a rotation speed of 300 rpm to mix them uniformly to prepare a powdery raw material mixture for use.

[0037] (2) Mix 10 g of jojoba oil, 5 g of avocado oil, and 7.5 g of sweet almond oil in a mass ratio, heat to 85°C, and perform magnetic stirring and dissolution at 300 rpm to obtain an oil phase.

[0038] (3) Heating 17 g of deionized water and 3 g of aloe extract to 85°C, magnetic stirring and dissolving at a speed of 300 rpm to obtain the water phase;

[0039] (4) Mix the heated oil phase and water phase, maintain a temperature of 85°C, and emulsify the mixture with magnetic stirring at a speed of 500 rpm for 20 minutes to drive away all bubbles.

[0040] (5) After cooling to 50°C, add the powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com