Novel non-hydrogenated vegetable cream and preparation method thereof

A vegetable butter, non-hydrogenated technology, applied in the production/processing of edible oil/fat components, edible oil/fat, etc., can solve the problems of harming human health, existing health risks, changing the composition of oil and fat, etc., and achieves high safety. , fine texture, pure flavor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

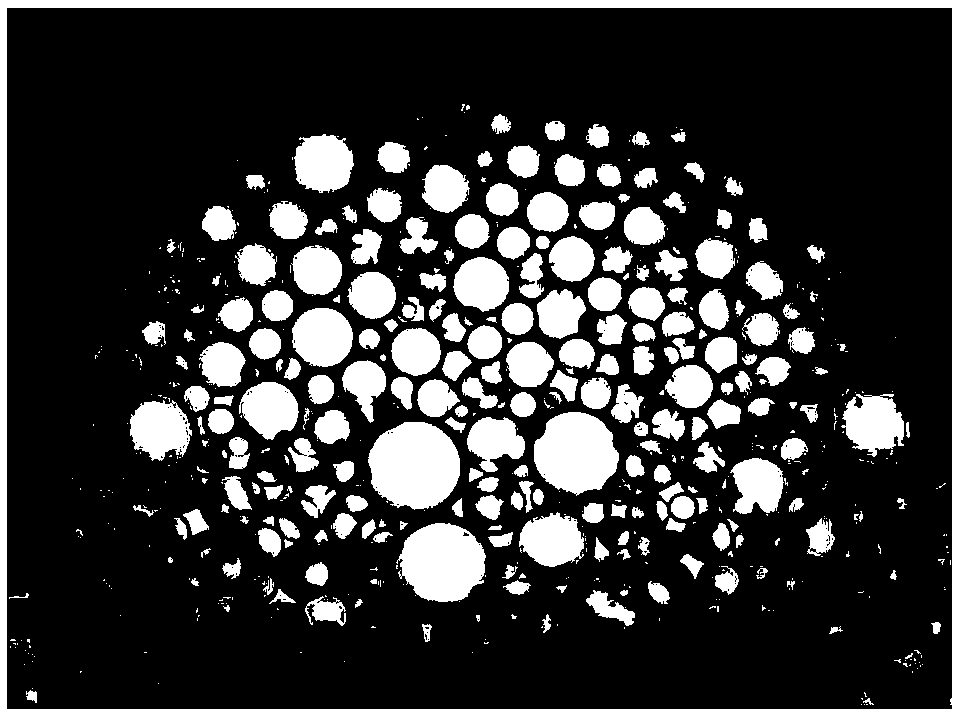

Image

Examples

Embodiment 1

[0025] Embodiment 1 A kind of preparation method of novel non-hydrogenated vegetable butter, comprises the following steps:

[0026] Weigh 20g of β-cyclodextrin and 20g of γ-cyclodextrin, add them into 300mL of water, and heat in a water bath at 60°C for 10 minutes to obtain a cyclodextrin solution; add 50g of white sugar and 10g of salt to the cyclodextrin solution, heat to dissolve evenly, Obtain cyclodextrin mixed solution; weigh 10g xanthan gum, add 100mL water to swell for 1h, then heat and dissolve under stirring to make xanthan gum solution; mix cyclodextrin mixed solution and xanthan gum solution, then add purple Perilla seed oil 1.6L, tea polyphenols 0.3g, V E 0.3g, cool to 20°C, use a homogenizer to carry out 30Mpa / 10Mpa two-stage homogenization treatment until it becomes creamy, and finally put it in a boiling water bath to stir and sterilize for 10min, cool to room temperature, and store at 4°C.

[0027] The obtained product perilla seed oil has a content of abou...

Embodiment 2

[0029] Embodiment 2 A kind of preparation method of novel non-hydrogenated vegetable butter, comprises the following steps:

[0030] Weigh 40g of β-cyclodextrin and 20g of γ-cyclodextrin, add them into 400mL of water, heat and dissolve to obtain a cyclodextrin solution; weigh 12g of xanthan gum, add them to the cyclodextrin solution, and then add the cyclodextrin solution with a weight of 6 % salt, 0.3% monosodium glutamate, high-pressure homogenization under 15MPa to obtain a uniform cyclodextrin mixture, adjust the pH to 9.0 with sodium bicarbonate; add 0.2% V of perilla seed oil weight to 1.8L perilla seed oil E , then add the cyclodextrin mixture, cool to 4°C, and immediately carry out colloid mill treatment twice until it becomes creamy, and finally place it in a water bath at 90°C for 10 minutes, cool to room temperature, and then store it at -18°C.

[0031] The obtained product has a perilla seed oil content of about 77% (mass fraction), an appearance of light milky yel...

Embodiment 3

[0033] Embodiment 3 A kind of preparation method of novel non-hydrogenated vegetable butter, comprises the following steps:

[0034] Weigh 50g of β-cyclodextrin, add it to 500mL of water, heat and dissolve to obtain a cyclodextrin solution; weigh 15g of xanthan gum, add it to the cyclodextrin solution, heat and stir evenly, and then add 10% of the weight of the cyclodextrin solution Sugar and 4% salt were homogenized under high pressure to obtain a homogeneous cyclodextrin mixture, and the pH was adjusted to 8.0 with sodium bicarbonate; in 1.5L perilla seed oil, 0.1% TBHQ of perilla seed oil weight was added (tertidine base hydroquinone), then add the above cyclodextrin mixture, cool to 10°C, 25MPa high-pressure homogenization treatment once, 10Mpa high-pressure homogenization treatment once again, until creamy, and centrifuge the obtained homogenate at 5000rpm After 10 minutes, the lower part of the water was discarded, and finally placed in a 90°C water bath to heat for 10 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com