Novel multifunctional mesoporous glass bracket with biological activity as well as preparation method and purpose thereof

A bioactive glass, multifunctional technology, applied in bone implants, medical science, prostheses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] Preparation and Characterization of Copper-Containing Mesoporous Glass Scaffolds

[0082] In a first aspect of the present invention, a multifunctional mesoporous bioactive glass scaffold is provided,

[0083] The bioactive glass support is an amorphous glass structure, and 90% to 99.999% of the macropores are interconnected;

[0084] The bioactive glass scaffold also contains 1 to 15 mol% copper, based on the CuO-CaO-P in the amorphous glass structure 2 o 5 -SiO 2 Calculate the amount of the total substance.

[0085] In a specific embodiment, the porosity of the bioactive glass scaffold is not lower than 85%.

[0086] In a specific embodiment, the mesoporous distribution of the bioactive glass scaffold is 2-9 nm, preferably 5±1 nm.

[0087] In a specific embodiment, the drug release of the bioactive glass stent can be maintained for 3-10 days, preferably 7±1 days.

[0088] In a specific embodiment, the antibacterial efficiency of the bioactive glass scaffold can ...

specific Embodiment approach

[0121] Mix and dissolve P123 and ethanol at a mass ratio of 1: (10-20), mix analytically pure ethyl orthosilicate and ethanol at a ratio of 1: (7-15), and adjust the pH value to 2-4 with hydrochloric acid. Stir well at room temperature for 60±10 minutes, then add calcium nitrate tetrahydrate, triethyl phosphate and copper chloride with different contents (Cu content: 1-15%). After stirring for 3-5 hours, it is used to coat the polyurethane sponge 3-5 times, dried at room temperature for 24 hours, and calcined at 600-750° C. for 3-8 hours.

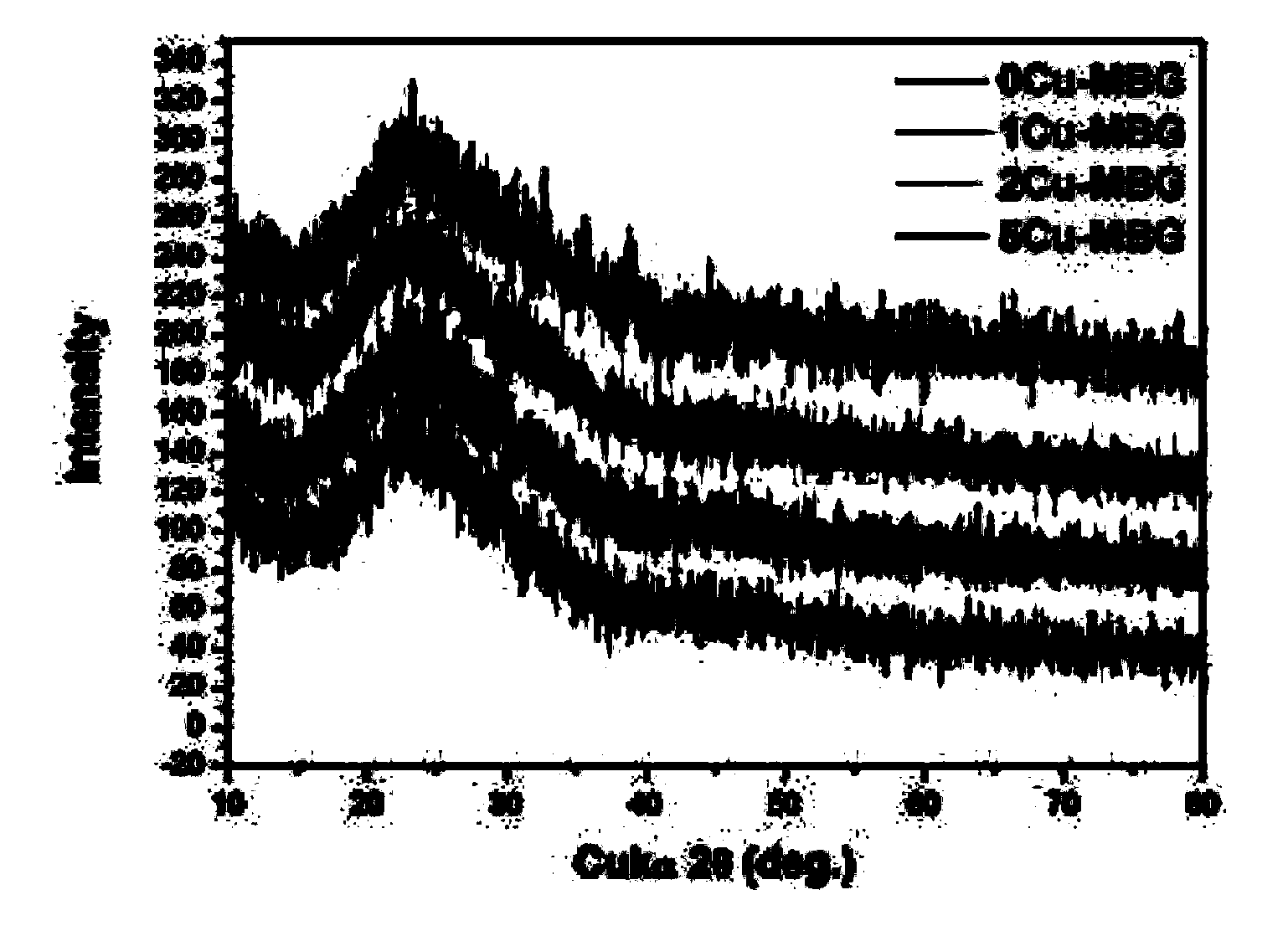

[0122] By XRD, TEM, SEM and N 2 The phase, mesoporous structure, macroporous structure, specific surface area and mesoporous pore volume of mesoporous glass scaffolds with different copper contents were systematically characterized by means of adsorption-desorption.

[0123] The impregnation, coating, drying, calcination, and usually cooling steps of the present invention can be carried out using equipment and methods conventional in the a...

example 1

[0148] Mix and dissolve P123 and ethanol at a mass ratio of 1:15, mix analytically pure ethyl orthosilicate and ethanol at a ratio of 1:8.7, adjust the pH value to 2 with hydrochloric acid, fully stir at room temperature for 60 minutes, and then add four Calcium nitrate hydrate, and triethyl phosphate and different content of copper chloride (Cu molar content: 0, 1, 2, 5%). After stirring for 5 hours, it was used to coat polyurethane sponge 3 times, dried at room temperature for 24 hours, and calcined at 650° C. for 5 hours.

[0149] Material characterization, vascularization, osteogenesis, drug delivery, and antimicrobial performance studies are then performed, such as Figure 1-13 shown.

[0150] The multifunctionality study of the copper-containing mesoporous glass support has the following conclusions:

[0151] (1) Angiogenesis potential of copper-containing mesoporous glass scaffolds

[0152] The mesoporous glass scaffolds with different copper contents were cultured w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com