Preparing method of high silicon electrical steel strip with gradient-distributed silicon content

A high-silicon electrical steel, gradient distribution technology, applied in the field of metallurgy, can solve problems such as low production efficiency and serious environmental pollution, and achieve the effects of high production efficiency, low environmental pollution, and reduction of high-frequency iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

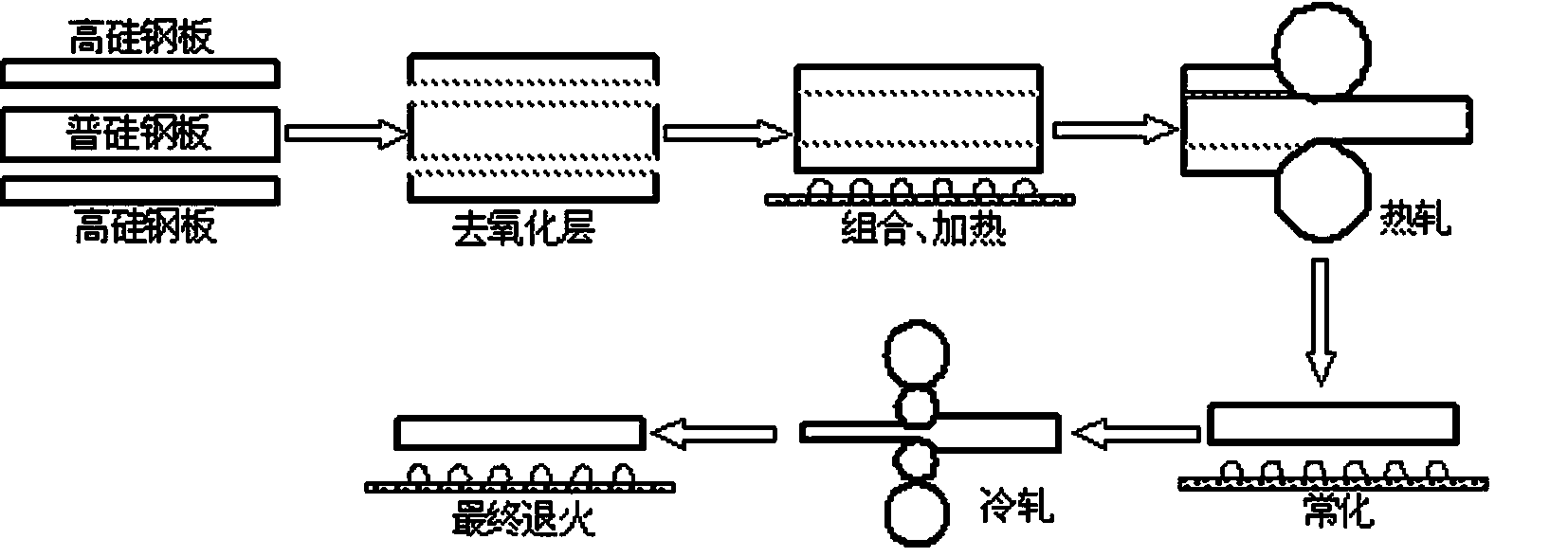

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the hot-rolled high-silicon steel plate in the embodiment of the present invention is as follows: the slab is made by melting and casting, and then hot-rolled. The starting temperature of the hot rolling is 1000-1200°C, and the finishing temperature is 700-1000°C. , The reduction rate is 50~99%.

[0030]The preparation method of the warm-cold-rolled high-silicon steel plate in the embodiment of the present invention is as follows: first, the slab is made by melting and casting, and then hot-rolled to make a hot-rolled high-silicon steel plate. The final rolling temperature is 700~1000°C, and the reduction rate is 50~99%; then the hot-rolled high silicon steel plate is subjected to warm and cold rolling, the temperature of warm and cold rolling is room temperature~690°C, and the reduction rate is 10~95%, Made into warm and cold rolled high silicon steel plate.

[0031] The ordinary silicon steel plate in the embodiment of the present invention ...

Embodiment 1

[0039] Prepare a high-silicon steel plate, its composition contains Si 7.0%, S 0.05%, P 0.05%, C 0.05% by weight percentage, and the balance is Fe and unavoidable impurities; the high-silicon steel plate is a hot-rolled high-silicon steel plate;

[0040] Prepare common silicon steel plate, its composition contains Si 3.5%, Al 1.0%, P 0.05%, S 0.05%, C 0.05% by weight percentage, the balance is Fe and unavoidable impurity; Common silicon steel plate is hot-rolled common silicon steel plate;

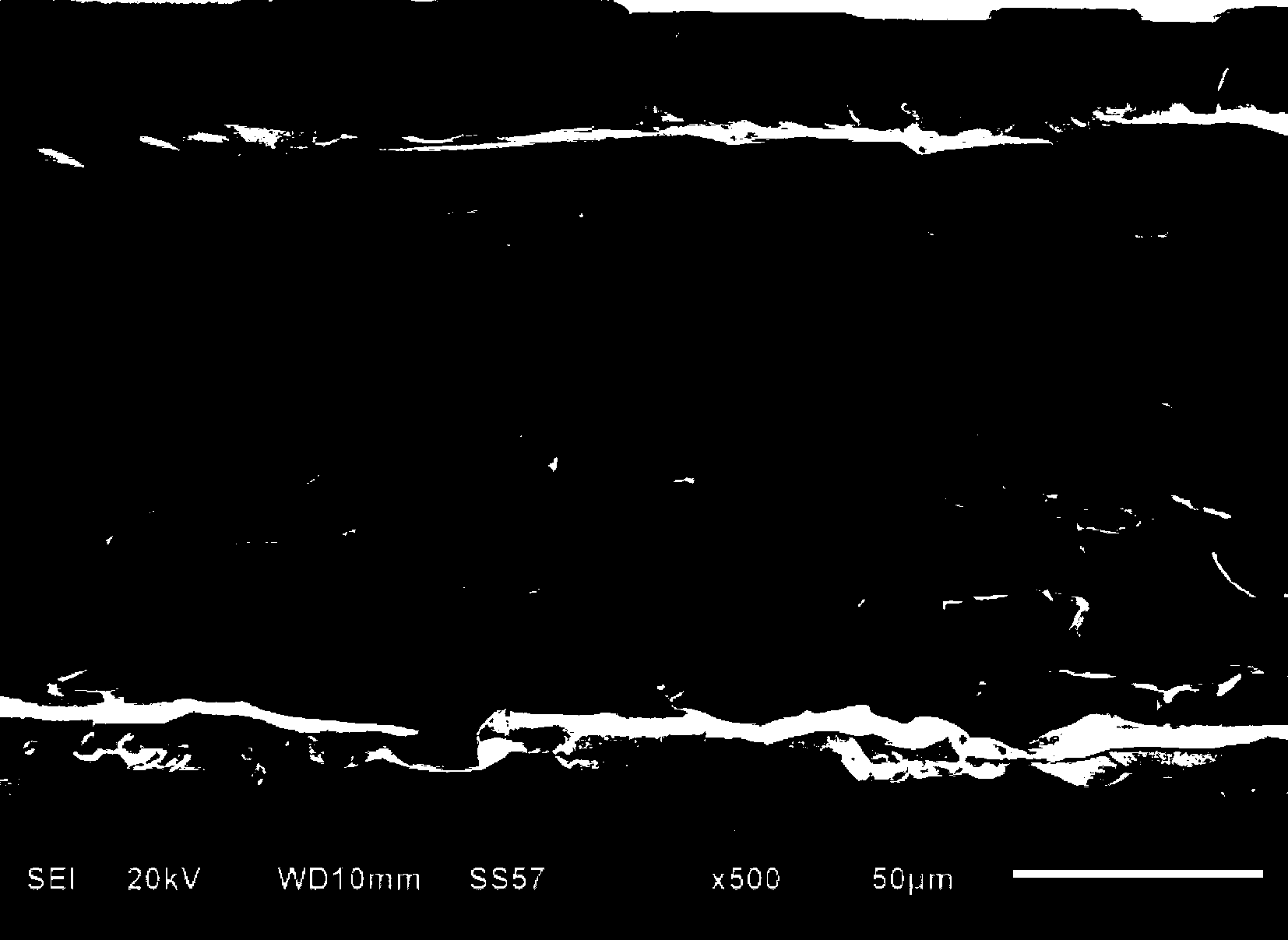

[0041] Select two high-silicon steel plates and one ordinary silicon steel plate with the same length and width; the thicknesses of the two high-silicon steel plates are 1mm and 3mm respectively, and the thickness of the ordinary silicon steel plate is 16mm; Each high-silicon steel plate removes the oxide layer on one surface; then the ordinary silicon steel plate is placed between two high-silicon steel plates, so that the surfaces of the high-silicon steel plate and the common silicon ste...

Embodiment 2

[0046] Prepare high-silicon steel plate, its composition contains Si 6.55%, Al 0.006%, Mn 0.01%, S 0.006%, P 0.008%, C 0.005% by weight percentage, the balance is Fe and unavoidable impurities; high-silicon steel plate is hot-rolled High silicon steel plate;

[0047] Prepare ordinary silicon steel plate, its composition contains Mn 0.002%, P 0.002%, S 0.003%, C 0.006% by weight percentage, the balance is Fe and unavoidable impurities; ordinary silicon steel plate is the slab made by melting and casting;

[0048] Select two high-silicon steel plates and one ordinary silicon steel plate with the same length and width; the thickness of the two high-silicon steel plates is 20mm, and the thickness of the ordinary silicon steel plate is 300mm; Remove the oxide layer on one surface of each plate; then place the ordinary silicon steel plate between two high silicon steel plates, so that the surfaces of the high silicon steel plate and the ordinary silicon steel plate with the oxide la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic sense | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Magnetic sense | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com