Preparation method of rare earth Nd containing Fe-6.9%Si strip

A thin strip and rare earth technology is applied in the field of steel rolling to achieve the effects of low production cost, improved texture strength and reduced high frequency iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

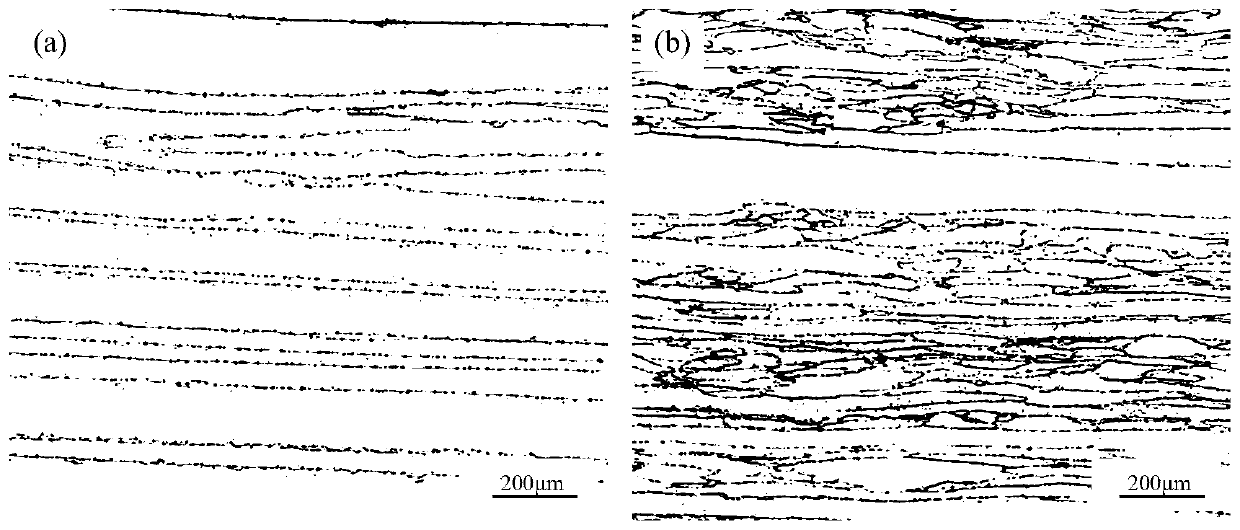

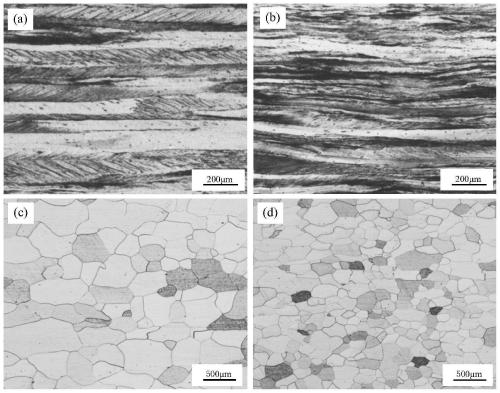

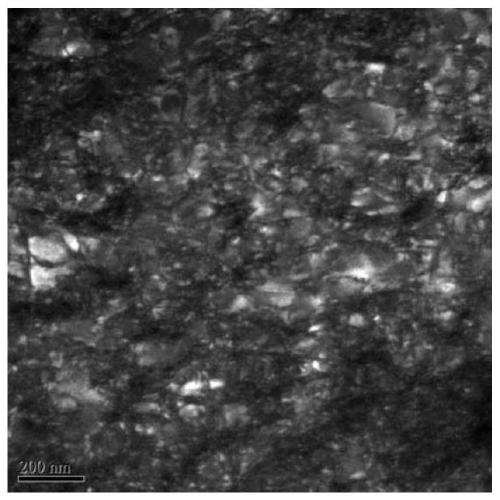

[0033] Vacuum induction furnace is used to cast high-silicon steel ingots, and its chemical composition is as follows: Si 6.95%, Nd 0.032%, C 0.008%, Mn 0.009%, P 0.005%, S 0.004%, N 0.002%, O 0.002% , the balance Fe. At a temperature of 1250°C, after holding for 220 minutes, the billet was free-forged into a 50mm thick billet by air. The heating temperature of the slab hot rolling is 1170°C, the holding time is 110min, and then asynchronous hot rolling is carried out on a reversible asynchronous hot rolling mill with a different speed ratio of 1.2, the lower roll speed is 0.6m / s, and the upper roll speed is 0.78m / s. The final rolling temperature is 880°C, after 10 passes of hot rolling to 3mm, water cooling.

[0034] Pickling with 5% concentration of hydrochloric acid solution and then warm rolling. In the first stage of the warm rolling process, the rolling plate is heated to 650°C, warm rolled to 2mm, the pass reduction rate is 14%, and the rolling force is 230kN. In the...

Embodiment 2

[0038] Vacuum induction furnace is used to cast high-silicon steel ingots, and its chemical composition is as follows: Si 6.91%, Nd 0.038%, C 0.009%, Mn 0.008%, P 0.004%, S 0.003%, N 0.001%, O 0.002% , the balance Fe. At a temperature of 1220°C, after 220 minutes of heat preservation, air free forging was used to form a 50mm thick billet. The heating temperature of the slab hot rolling is 1150°C, the holding time is 100min, and then asynchronous hot rolling is carried out on a reversible asynchronous hot rolling mill with a different speed ratio of 1.2, the lower roll speed is 0.5m / s, and the upper roll speed is 0.6m / s. The final rolling temperature is 890°C, after 10 passes of hot rolling to 2.7mm, it is water-cooled.

[0039] Pickling with 7% concentration of hydrochloric acid solution and then warm rolling. In the first stage of the warm rolling process, the rolling plate is heated to 680°C, warm rolled to 1.7mm, the pass reduction rate is 13%, and the rolling force is 22...

Embodiment 3

[0043] Vacuum induction furnace is used to cast high-silicon steel ingots, and its chemical composition is as follows: Si 6.96%, Nd 0.043%, C 0.008%, Mn 0.009%, P 0.004%, S 0.004%, N 0.002%, O 0.002% , the balance Fe. At a temperature of 1200°C, after holding for 210 minutes, it is free-forged into a 50mm-thick billet by air. The heating temperature of the slab hot rolling is 1170°C, the holding time is 90min, and then asynchronously hot rolling, the speed ratio is 1.3, the roll speed of the lower roll is 0.4m / s, and the roll speed of the upper roll is 0.52m / s. The final rolling temperature is 900°C, after 11 passes of hot rolling to 2.3mm, it is water-cooled.

[0044] Pickling with 7% concentration of hydrochloric acid solution and then warm rolling. In the first stage of the warm rolling process, the rolling plate is heated to 700°C, warm rolled to 1.5mm, the pass reduction rate is 12%, and the rolling force is 210kN. In the second stage, the rolled plate is heated to 580°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com