Continuous polymerization preparation method of flame-retardant anti-static PTT (polytrimethylene terephthalate) polyester and polyester prepared by using same

A flame retardant, antistatic, PTT technology, applied in the field of polyester, can solve the problems of complex masterbatch preparation process, etc., and achieve the effects of easy large-scale industrial production, easy continuous operation, and strong market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

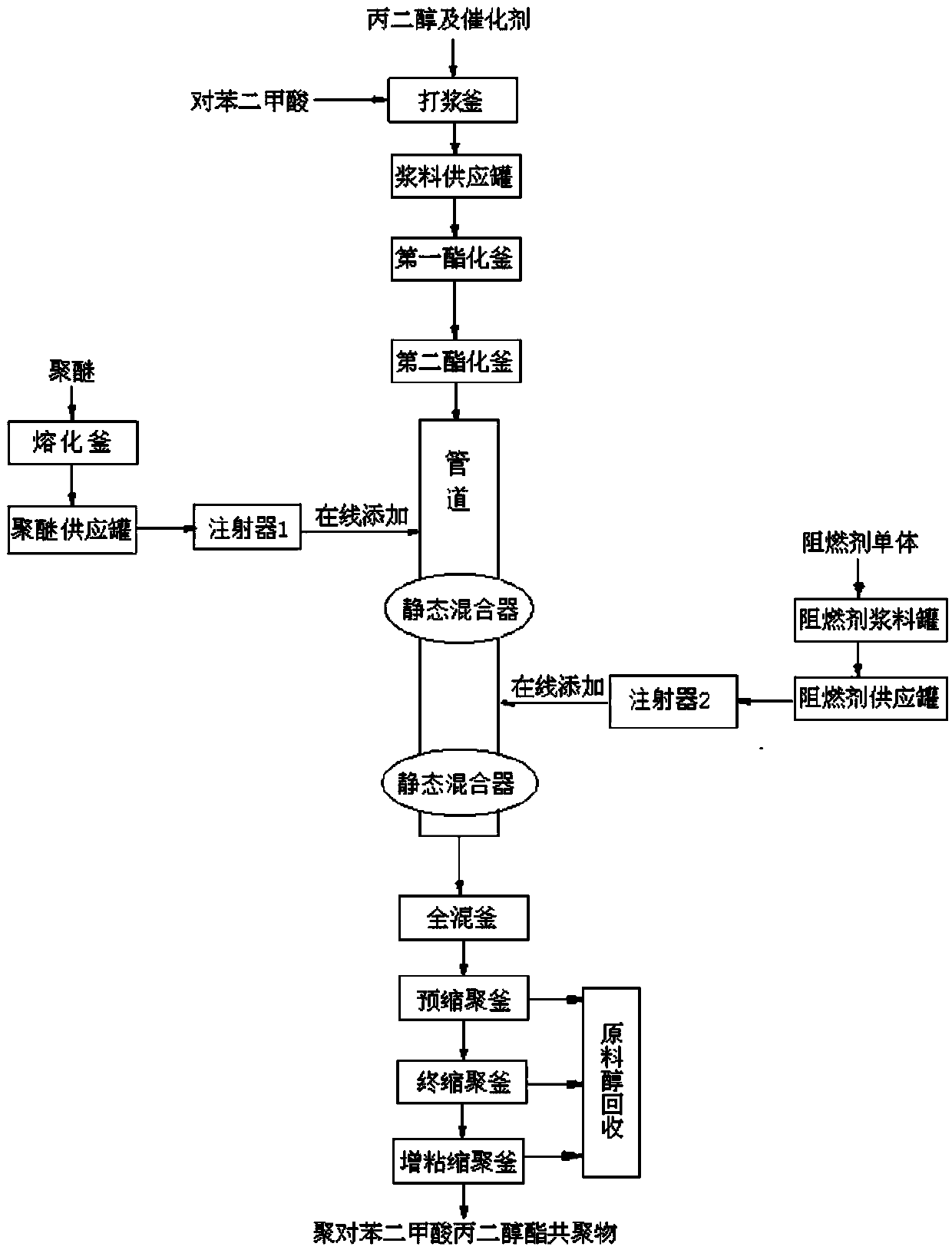

[0064] 1. Put terephthalic acid (PTA) and propylene glycol (PDO) into the beating kettle, add tetrabutyl titanate for beating, beat for 40 minutes, and put it into the slurry supply tank; the molar ratio of terephthalic acid and propylene glycol is 1:1.5, the amount of tetrabutyl titanate added is 0.04% of the total reactant mass;

[0065] 2. Pump the slurry obtained in step 1 into the first esterification tank to carry out the esterification reaction. The esterification temperature is 250-255°C, and the flow rate is controlled so that after passing through the first esterification tank, the esterification rate is 85-255°C. 90%; then enter the second esterification kettle, the esterification temperature is 257-260°C, and the esterification rate is controlled at 97-98%; the obtained esterified product is pumped into the pipeline, and the pipeline passes through the injector 1 and the injector 2 in turn;

[0066] 3. Melt polyethylene glycol ether with a molecular weight of 1000 ...

Embodiment 2

[0072] 1. Put terephthalic acid (PTA) and propylene glycol (PDO) into the beating kettle, add tetraethyl propyl titanate for beating, beat for 30 minutes, and put it into the slurry supply tank; the molar ratio of terephthalic acid to propylene glycol The ratio is 1:1.5; the amount of tetraethylpropyl titanate added is 0.05% of the weight of PTT polyester;

[0073] 2. Pump the slurry obtained in step 1 into the first esterification tank to carry out the esterification reaction. The esterification temperature is 245-255°C, and the flow rate is controlled so that after passing through the first esterification tank, the esterification rate is 80-255°C. 90%; then enter the second esterification reaction kettle, the esterification temperature is 255-260°C, and the esterification rate is controlled at 97-98%; the obtained esterified product is pumped into the pipeline, and the pipeline passes through the injector 1 and the injector 2 in turn;

[0074] 3. Melt PTMG in the melting tan...

Embodiment 3

[0080] 1. Put terephthalic acid (PTA) and propylene glycol (PDO) into the beating kettle, add tetrabutyl titanate for beating, after beating for 50 minutes, put them into the slurry supply tank; the molar ratio of terephthalic acid to propylene glycol 1:1.5; the amount of esterification catalyst added is 0.03% of the weight of PTT polyester;

[0081] 2. Pump the slurry obtained in step 1 into the first esterification tank to carry out the esterification reaction. The esterification temperature is 245-255°C, and the flow rate is controlled so that after passing through the first esterification tank, the esterification rate is 85-255°C. 90%; then enter the second esterification reaction kettle, the esterification temperature is 255-260°C, and the esterification rate is controlled at 96-98%; the obtained esterified product is pumped into the pipeline, and then passes through the injector 1 and the injector 2 in turn;

[0082] 3. Mix 2-hydroxyethylphenylphosphinic acid with a cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com