Interior wall putty powder

A technology of interior wall putty powder and ash calcium powder is applied in the field of interior wall putty powder, which can solve the problems of poor versatility of interior wall putty powder, and achieve the effects of low cost, strong versatility and good water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

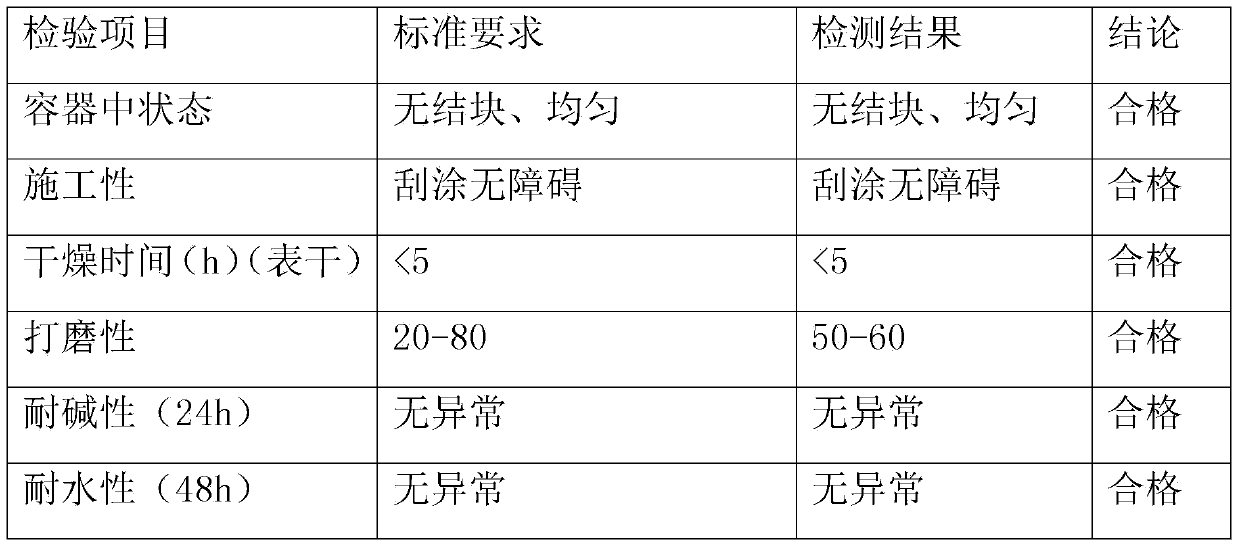

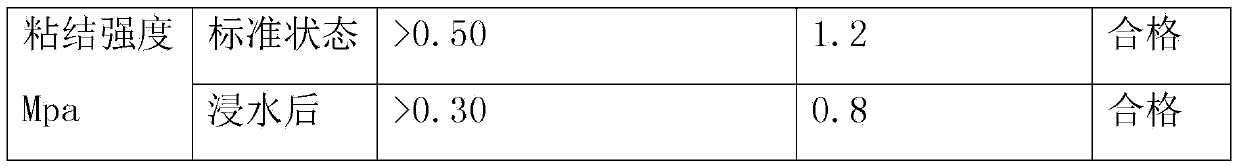

[0016] Embodiment one standard interior wall putty powder

[0017] It consists of the following raw materials: 800kg of heavy calcium carbonate powder; 150kg of gray calcium powder; 50kg of white cement; 4.5kg of HPMC; Using heavy calcium carbonate powder as the main filler of putty powder can enhance the strength of putty powder, improve surface gloss and surface smoothness, and because the whiteness of calcium carbonate is above 90, it can also replace expensive white pigments and reduce the production of putty powder Cost; preferably, the gray calcium powder used is 800 mesh, the whiteness is greater than 95%, the cost of the gray calcium powder is low, and the leveling of the gray calcium powder and the feel of the coating are good; the white cement is white silicate The abbreviation of cement is a hydraulic cementitious material made by adding gypsum to white portland cement clinker and grinding it. Its typical characteristics are high whiteness and bright color. Preferab...

Embodiment 2

[0018] Embodiment 2 sleeping health care type interior wall putty powder

[0019] It consists of the following raw materials: heavy calcium carbonate powder 850kg, gray calcium powder 180kg, white cement 60kg, HPMC 5.5kg, ultramarine 0.8kg, turmeric powder 5kg; preferably, the heavy calcium carbonate powder used is 800 mesh, whiteness greater than 95%; preferably, the gray calcium powder used is 800 mesh, and the whiteness is greater than 95%; preferably, the fineness particle size of white cement in the interior wall putty powder of the present invention is 600 mesh, and the whiteness is greater than 90%; preferably Yes, the viscosity of the HPMC is 80,000 to 100,000 mPa·s; the volatile oil of turmeric has a significant analgesic effect, and the turmeric diketone contained in the volatile oil has a stronger central inhibitory effect and plays a stronger Hypnosis and calming the nerves health care effect, so the putty powder containing turmeric composition of the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fine particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com