Low-carbon multi-element high-resistance electrothermal alloy and preparation method thereof

An electrothermal alloy, high-resistance technology, applied in the field of alloy materials, can solve the problems of urgent need to improve strength and oxidation resistance, shorten service life, limit the scope of use, etc., so as to improve high-temperature mechanical properties and oxidation resistance, improve alloy strength, The effect of improving the morphology of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is further illustrated and understood by the following examples.

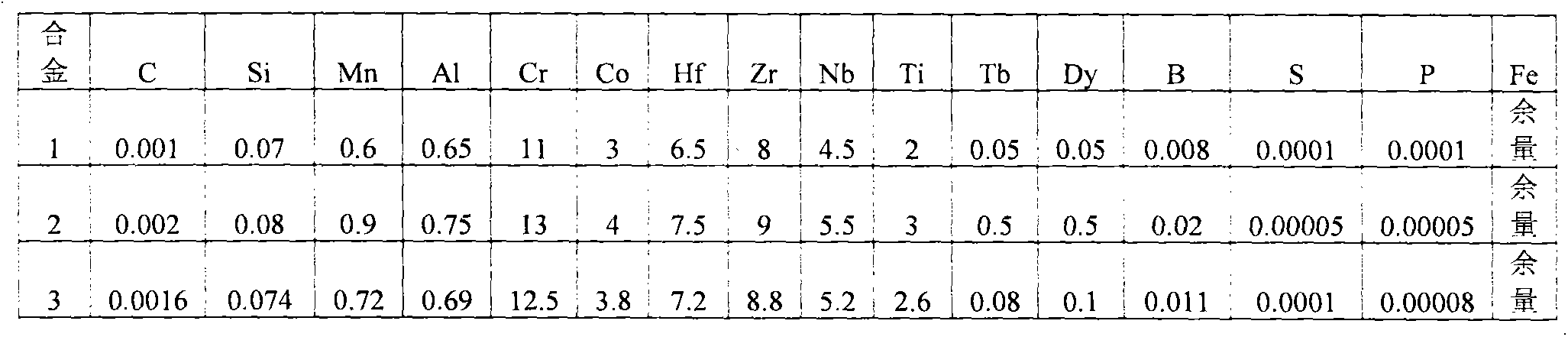

[0011] The element ratios of Examples 1-3 are shown in Table 1.

[0012] The element ratio (wt%) of table 1 embodiment 1-3

[0013]

[0014] The finished alloy products of Examples 1-3 were prepared according to the following methods: (1) Ingredients: ingredients were made according to the composition in Table 1; (2) Smelting: the above-mentioned raw materials were put into a magnetic levitation vacuum induction melting furnace, and the vacuum was evacuated to 1×10 -3 Pa, filled with high-purity argon to 1×10 4 Pa, smelted at 2900 ℃ and then cooled into alloy ingots with the furnace; (3) Homogenization annealing: put the alloy ingots into the vacuum heat treatment furnace, and the vacuum degree is 1×10 -3 Pa. The temperature is 1100°C for 36 hours and then cooled with the furnace; (4) Isothermal forging: The homogenized and annealed samples are processed into cylindrical ingots...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com