Double-acting steel flap gate

A flap gate, double-acting technology, applied in the field of gates, can solve the problems of general strength, many redundant constraints, and difficult construction, and achieve the effect of reducing the submerged area, obvious technical advantages, and avoiding frequent replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

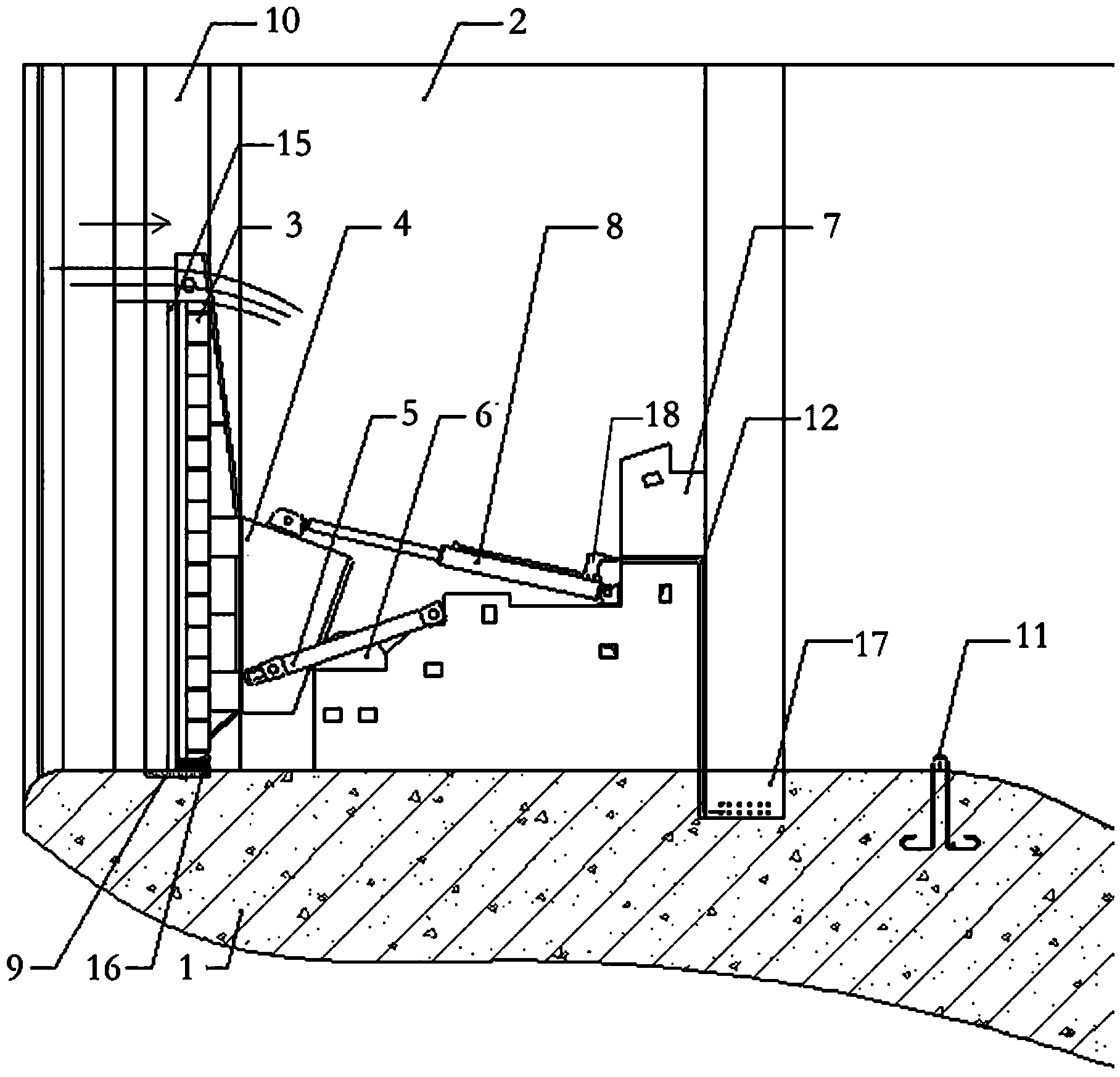

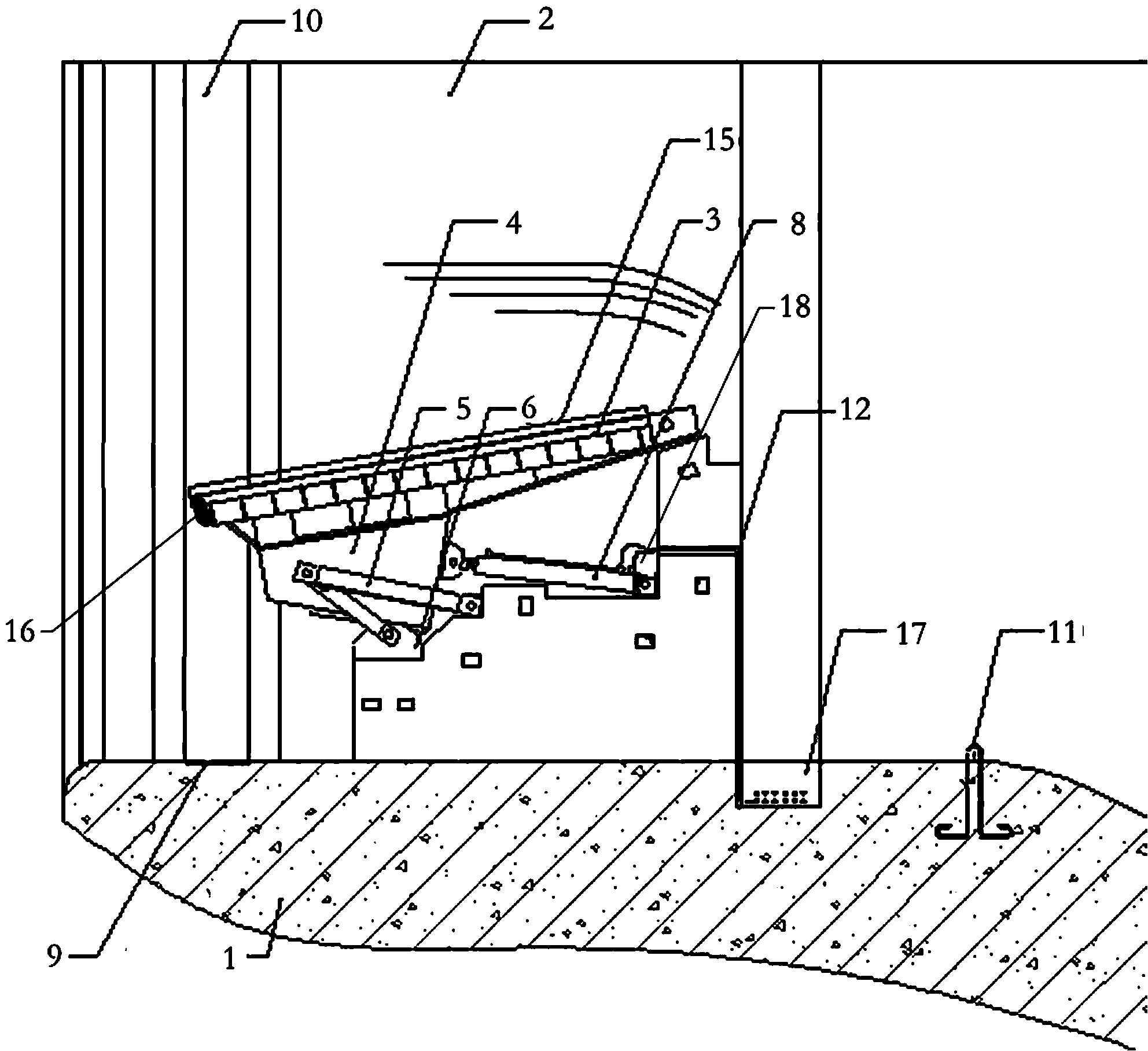

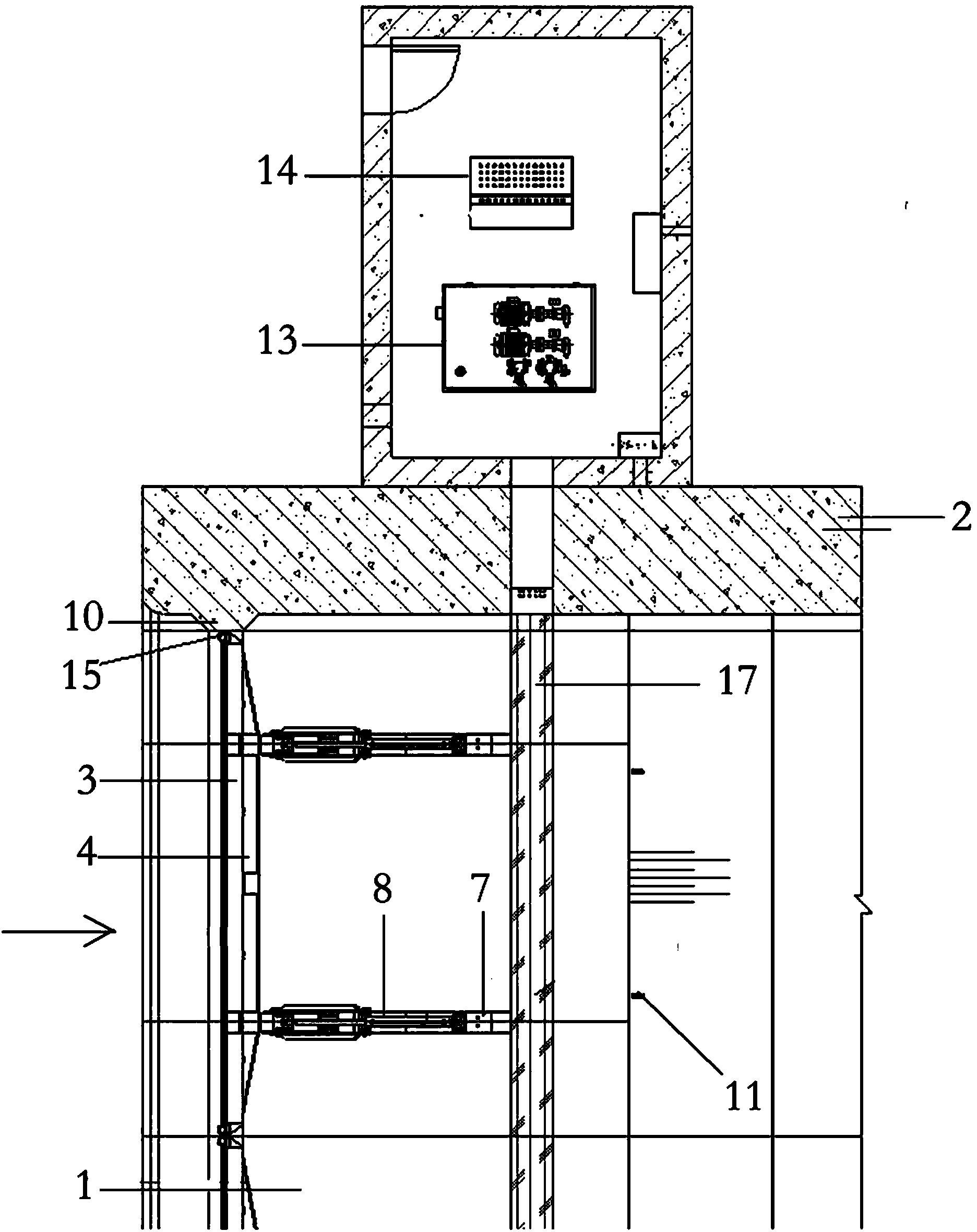

[0022] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0023] refer to figure 1 , figure 2 and image 3 , the steel double-action flap gate of the present invention comprises: a dam foundation 1 with a bottom water-stop interface 9 and a side wall 2 with a side water-stop interface 10, the bottom water-stop interface 9 is preferably flush with the dam foundation 1, and the side water-stop interface 10 preferably protrudes from the side wall 2, and a buttress 7 is buried on the dam foundation 1, and the buttress 7 is preferably stepped. In addition, it also includes: a steel door leaf 3, a bracket 4 fixed on the back of the steel door leaf 3, the lower part of the bracket 4 is connected with a linkage device 5, the linkage device 5 is connected with the pier 7, and the upper part of the bracket 4 is connected with an oil cylinder 8 , the other end of the oil cylinder 8 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com