Distributed type optical fiber sensing device and method for simultaneously measuring temperature, strain and vibration

A distributed optical fiber and sensing device technology, which is applied in the transmission of sensing components, measuring devices, instruments, etc. using optical devices, can solve problems such as inability to measure strain, and achieve the goal of avoiding strain demodulation distortion, reducing costs, and avoiding differences. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

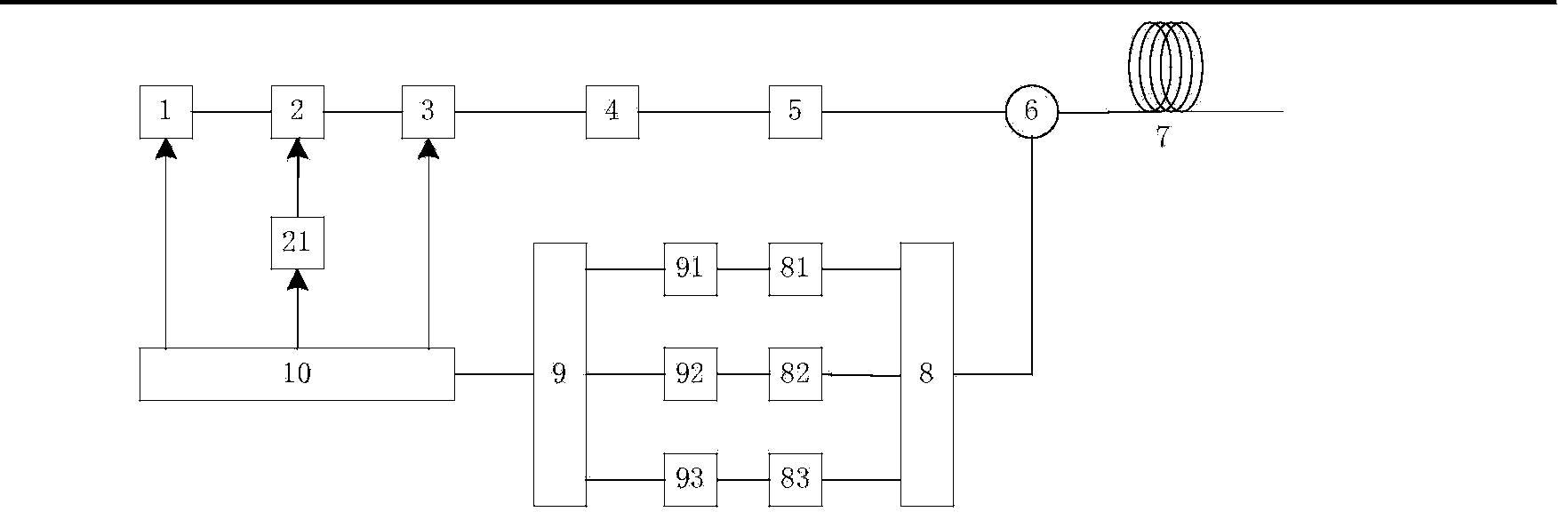

[0020] As shown in the figure, a distributed optical fiber sensing device includes: a frequency stabilized laser 1, a single sideband modulator 2, an optical pulse generator 3, an optical amplification unit 4, a polarization scrambling unit 5, an optical circulator or an optical coupling device 6, sensing optical fiber 7, spectroscopic unit 8, first photodetector 91, second photodetector 92, third photodetector 93, high-speed data acquisition unit 9 and system control and data processing unit 10, system control and The data processing unit 10 is electrically connected to the frequency-stabilized laser 1 and the optical pulse generator 3 respectively, the system control and data processing unit 10 is electrically connected to the SSB modulator 2 through the microwave generator 21, and the frequency-stabilized laser 1 emits a laser with a stable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com