Forming method of packaging structure

A technology of packaging structure and metal layer, which is applied in the manufacture of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc. , the effect of increasing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

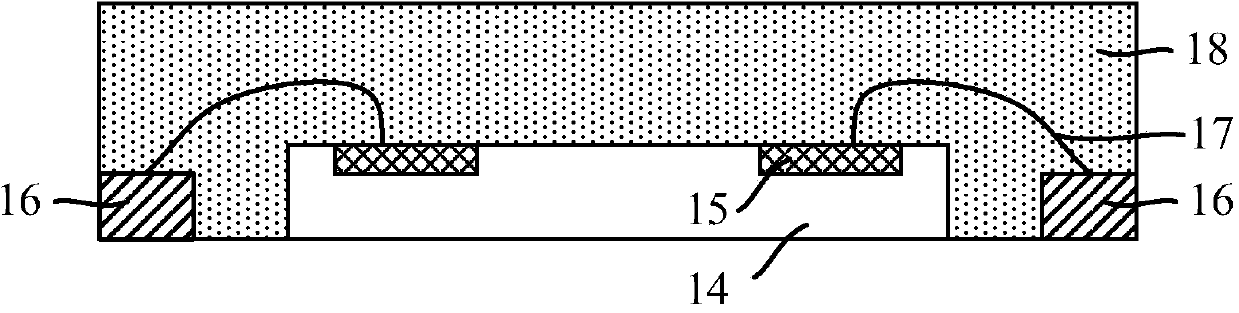

[0022] The integration level of the existing packaging structure is low, please refer to figure 1 , the pins 16 in the existing packaging structure are arranged around the semiconductor chip 14, and the pads 15 on the semiconductor chip 14 need to be electrically connected to the surrounding pins 16 through metal wires 17, so that the entire packaging structure occupies The larger volume is not conducive to the improvement of the integration degree of the packaging structure.

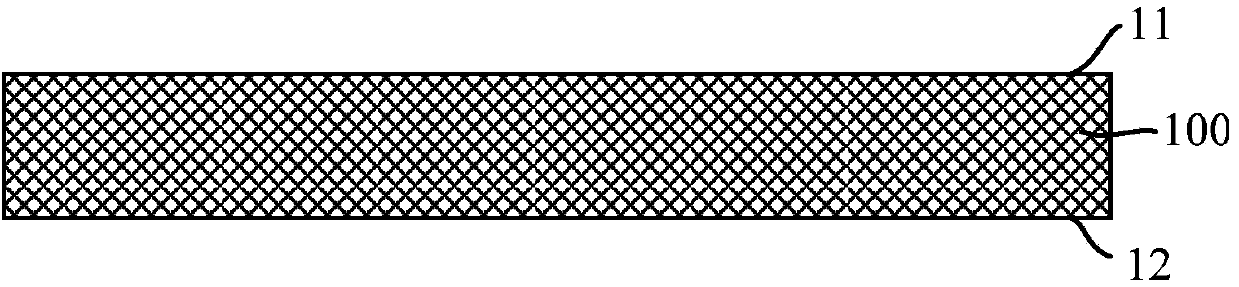

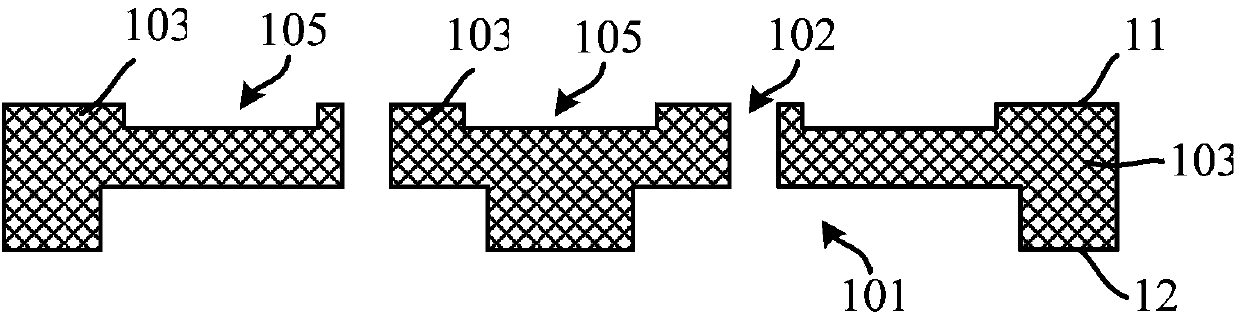

[0023] The invention provides a method for forming a packaging structure. The semiconductor chip is flipped over the pins, and the second metal bump on the semiconductor chip is welded together with the solder layer on the surface of the first metal bump, which reduces the size of the package. The volume of the structure increases the degree of integration.

[0024] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com