LED structure with high light extraction efficiency and manufacturing method thereof

A technology of LED structure and high light extraction, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of high technical difficulty, high cost, complex preparation process, etc., to improve the probability of vertical emission, improve light extraction efficiency, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention are described below through specific examples, and those skilled in the art can understand other advantages and functions of the present invention by referring to the specific embodiments disclosed in this specification. It is to be understood that other embodiments may be utilized and structural and functional modifications may be made without departing from the scope of the present invention.

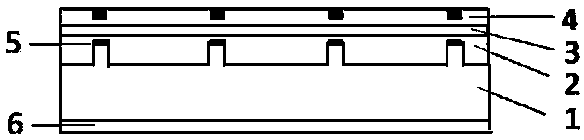

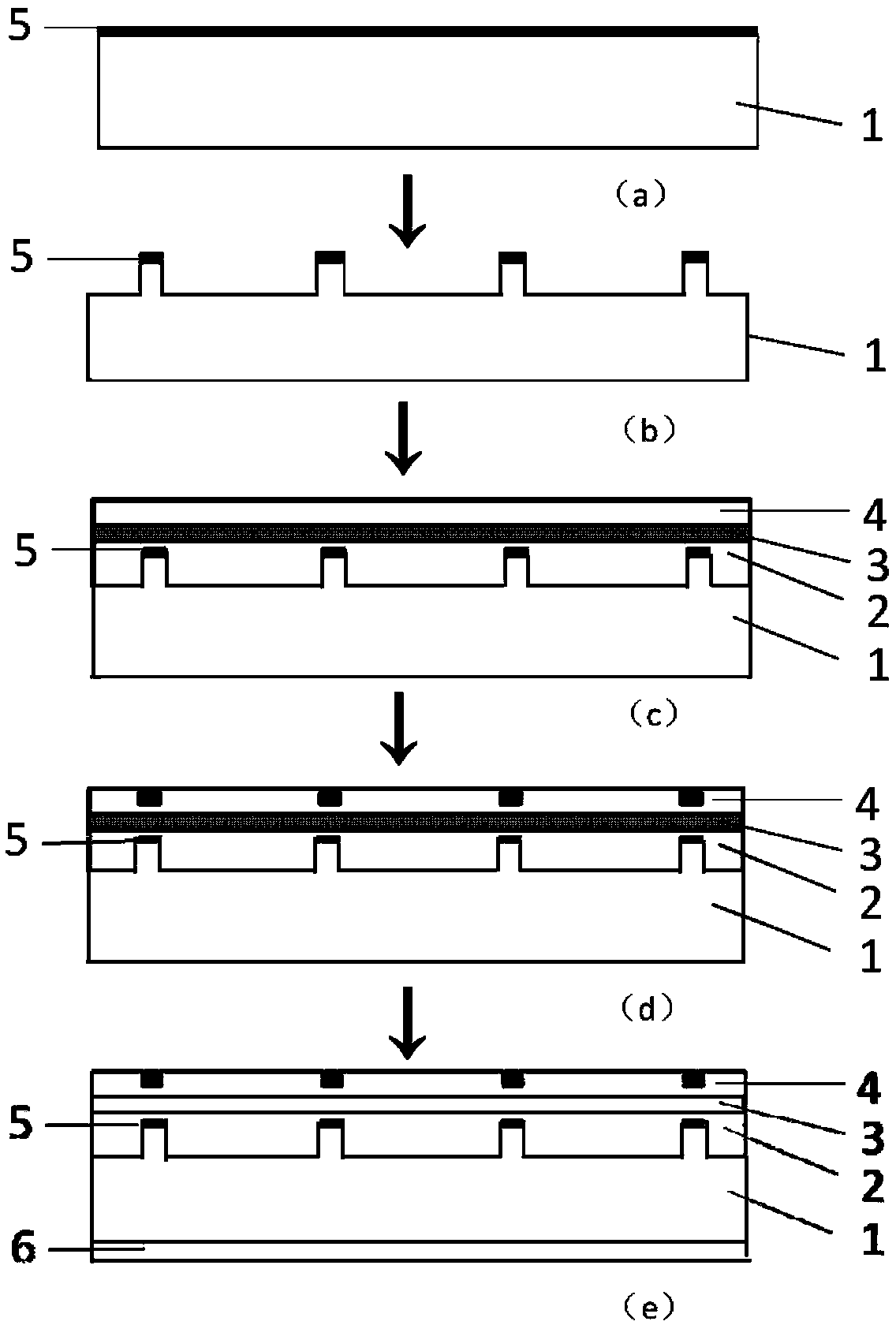

[0040] The LED structure with high light extraction efficiency provided by the present invention will be further described in detail below in conjunction with specific examples, as figure 2 Shown is a GaN LED fabrication method with a photonic crystal structure, including the following steps:

[0041] First proceed to step 1, such as figure 2 (a) shown. A preferred solution as this embodiment is:

[0042] In the first step, a sapphire pattern substrate 1 is provided, and SiH4 (silane) and NH3 (ammonia) are used as source gases, such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com