Gas analyzer

一种气体分析、气体的技术,应用在测量装置、分析材料、通过光学手段进行材料分析等方向,能够解决高温、易老化、分析装置大型化等问题,达到分析精度良好、降低制造成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

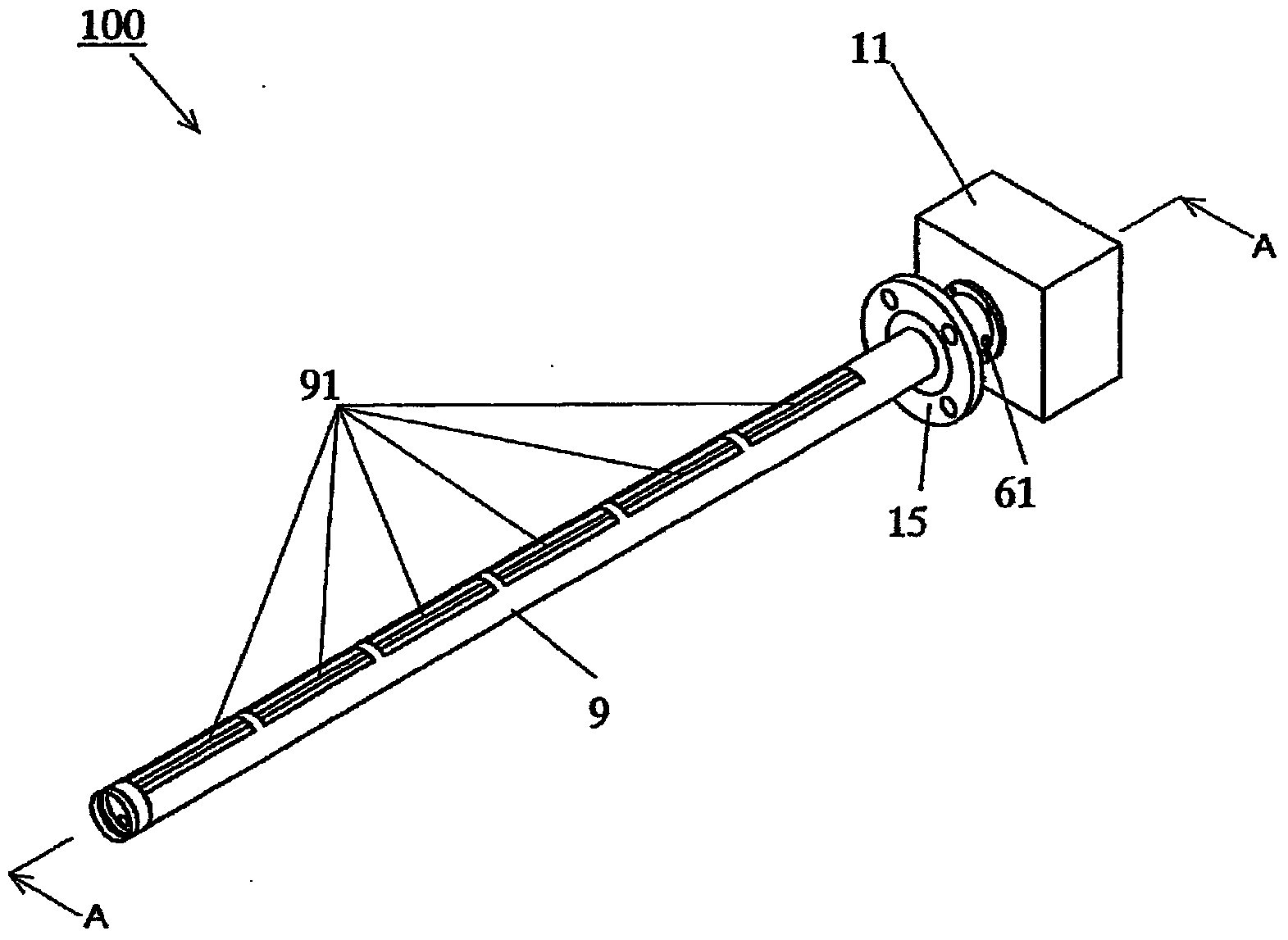

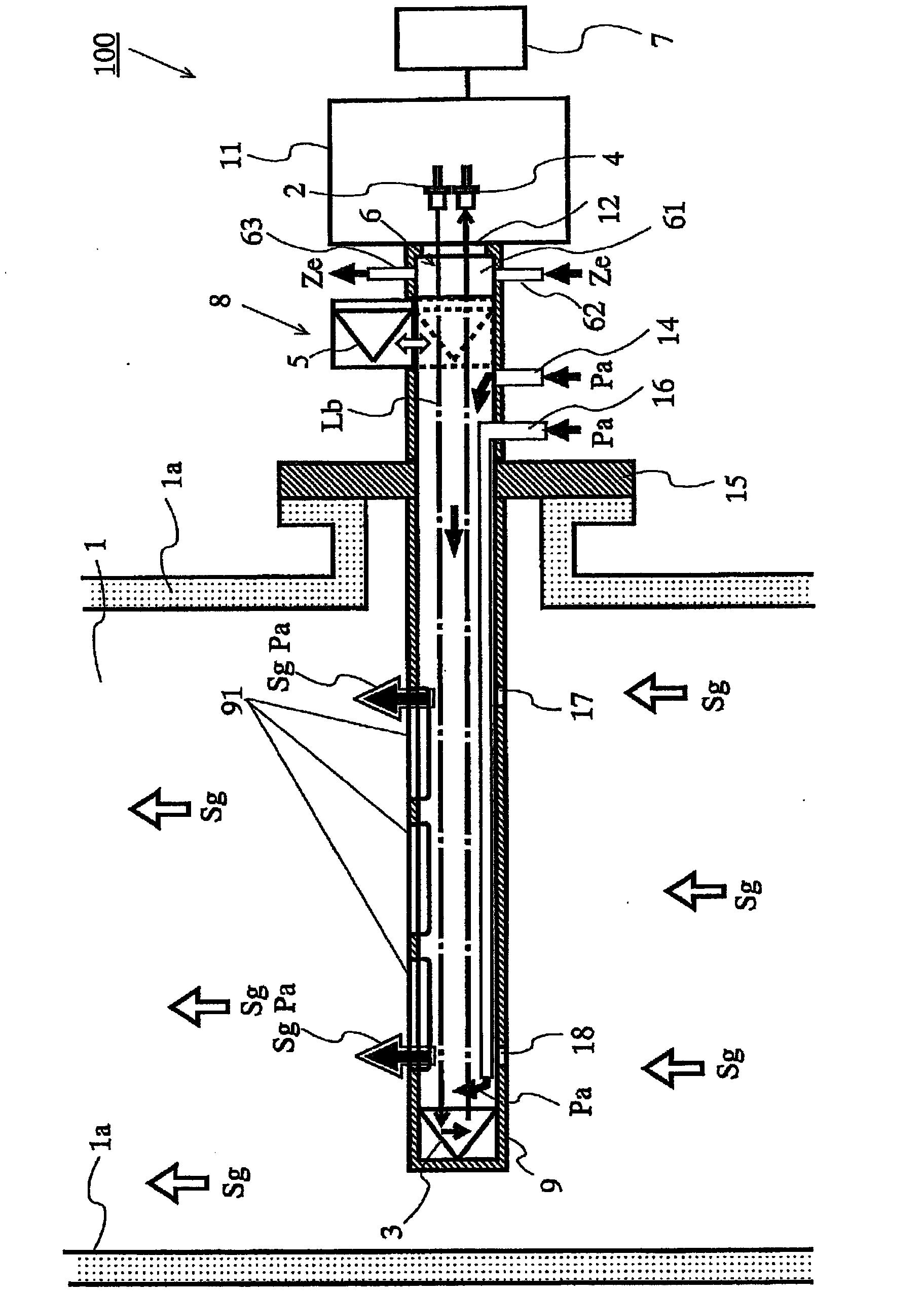

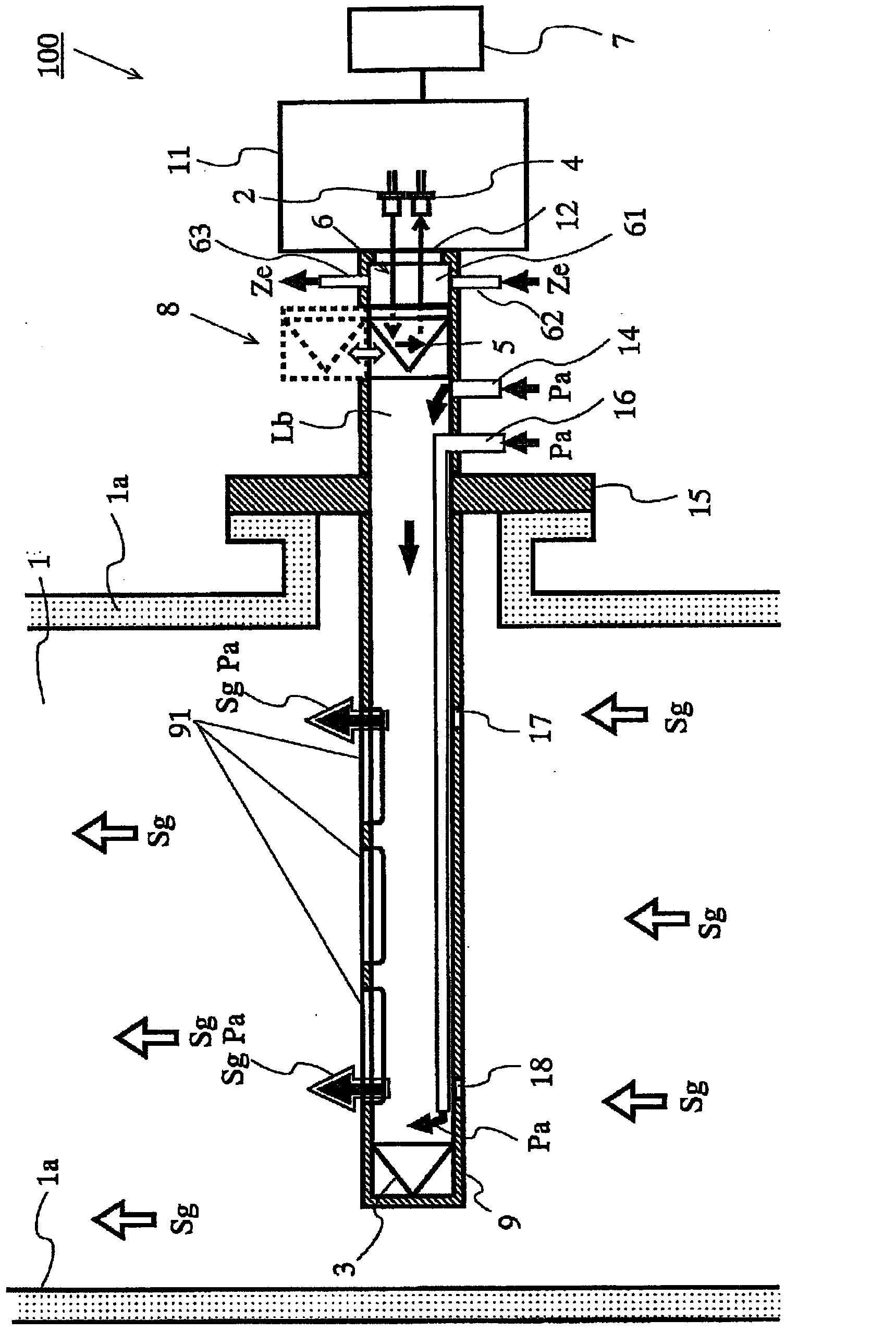

[0086] Next, the gas analysis device 100 of the first embodiment will be described. The gas analysis device 100 is a so-called probe type gas analysis device. figure 1 It is an external configuration diagram of the gas analysis device of the first embodiment. figure 2 Yes figure 1 The diagram including the A-A section of the gas analysis device shown is a diagram showing a gas concentration analysis mode. image 3 Yes figure 1 The figure including the A-A cross section of the shown gas analysis device is a figure showing a correction mode or a calibration mode.

[0087] The gas analysis device 100 of the first embodiment is a gas analysis device for analyzing the concentration of a predetermined component in a sample gas flowing through the flue 1 . The gas analysis device 100 is, for example, a non-dispersive infrared analyzer (Non-dispersive Infrared Analyzer: NDIR).

[0088] like figure 2 , image 3 As shown, the gas analysis device 100 includes: an irradiation uni...

no. 2 approach )

[0130] Next, the gas analysis device 200 of the second embodiment will be described. The gas analysis device 200 is a so-called open hole type gas analysis device. Figure 8 It is a sectional view showing the internal structure of the gas analysis device according to the second embodiment, and is a view showing a gas concentration analysis mode. Figure 9 It is a sectional view showing the internal structure of the gas analysis device according to the second embodiment, and is a view showing a zero point correction mode. The difference between the second embodiment and the first embodiment will be mainly described, and the same reference numerals will be assigned to the same structures as those of the first embodiment, and descriptions thereof will be omitted.

[0131] In the second embodiment, as Figure 8 , Figure 9 As shown, the gas analysis device 200 is composed of a first unit 19 and a second unit 20 formed in a separate body. The first unit 19 is installed on one s...

no. 3 approach )

[0145] use Figure 10 ~ Figure 13 A third embodiment will be described. The third embodiment differs from the embodiment only in the structure supporting the second mirror 5 . Figure 10 It is a sectional view showing the structure of the switching unit of the third embodiment, and is a view showing a correction mode or a calibration mode. Figure 11 is a perspective view of a bearing. Figure 12 is a top view of the bearing. Figure 13 Yes Figure 10 A partial enlargement of the .

[0146] The second mirror 5 is held by the mirror holder 104 .

[0147] like Figure 10As shown, in the above embodiment, the forward and backward moving mechanism has a positioning mechanism 101, and when the cylinder 84 returns the second reflecting mirror 5 to the optical path, the positioning mechanism 101 is used to make the second reflecting mirror 5 always face the same direction and It is positioned at the same location.

[0148] The positioning mechanism 101 is disposed below the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com