Crystallizer Vibration Control Device Based on CAN Bus

A CAN bus and crystallizer technology, applied in the field of continuous steel casting, can solve the problems of high cost, inability to complete work tasks, and the inability of the machine to independently complete parameter modification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

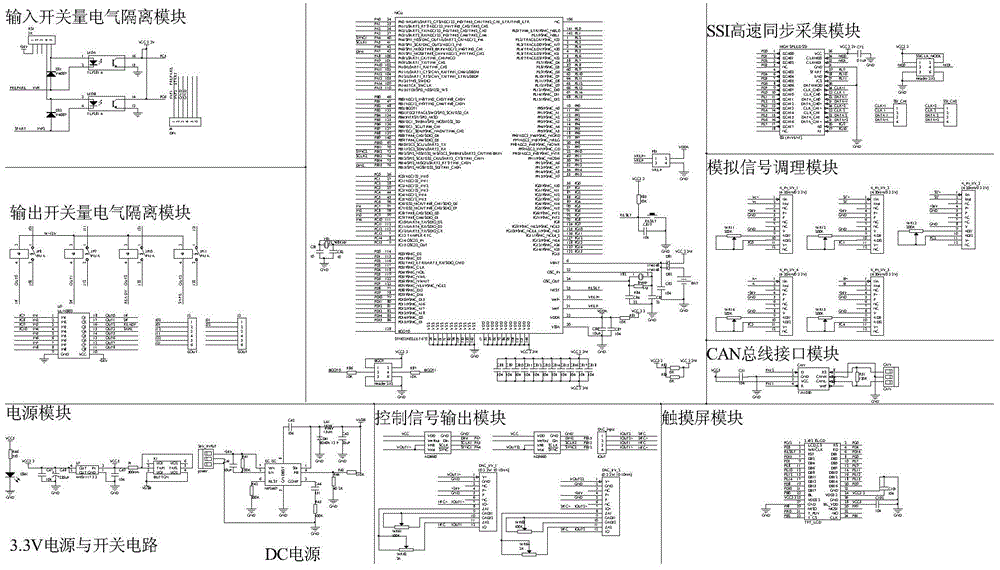

Image

Examples

Embodiment Construction

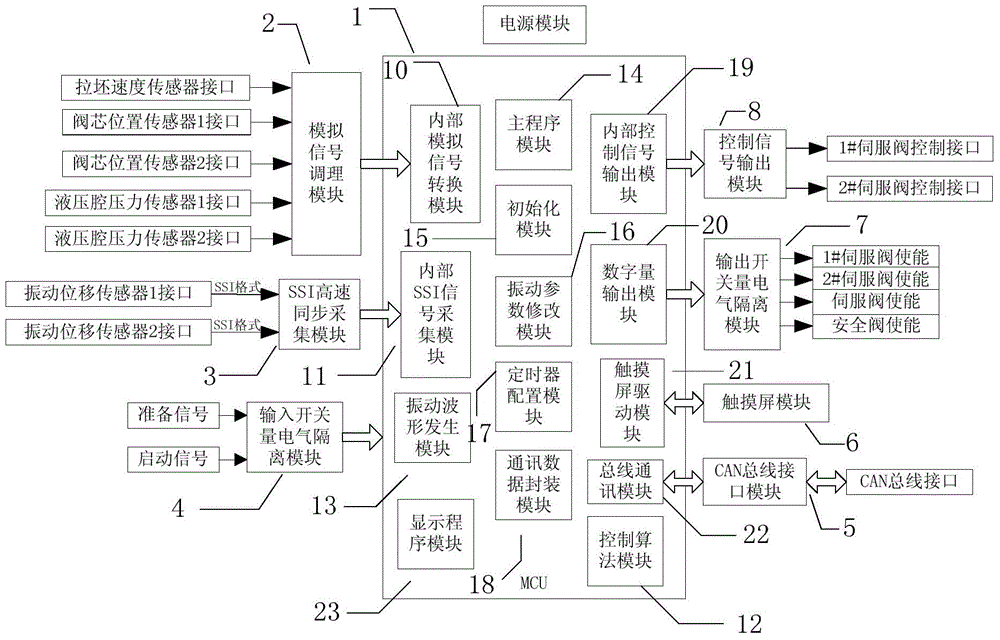

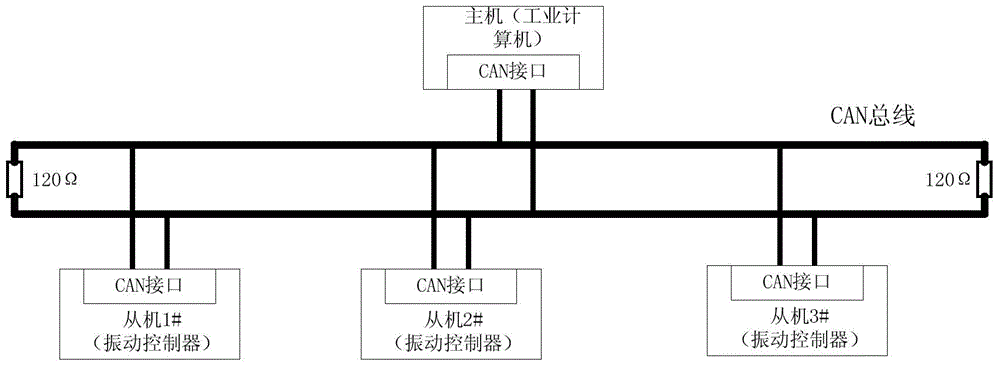

[0086] (1) Construction of the mold multi-flow vibration control system based on CAN bus

[0087] The control device can be used to realize a fieldbus-based crystallizer multi-flow vibration control system. Such as figure 2 As shown, in this control system, the crystallizer vibration controller controls the hydraulic vibration device to vibrate according to the set vibration curve by generating vibration waveforms to complete the production task. The host (host computer) communicates with the slave (vibration controller) through the CAN bus. In this system, the master machine can monitor the multi-flow vibration control process of the crystallizer, modify the vibration and control parameters online, and send them to the slave machine to directly control the vibration process. The slave machine (vibration controller) directly collects field data and generates vibration waveforms. After data processing and calculation, it controls the servo valve of the hydraulic cylinder. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com