Method for improving wood density of planted forest

A technology of artificial forest and wood, applied in the direction of pressure impregnation, etc., can solve the problems of poor material and high proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

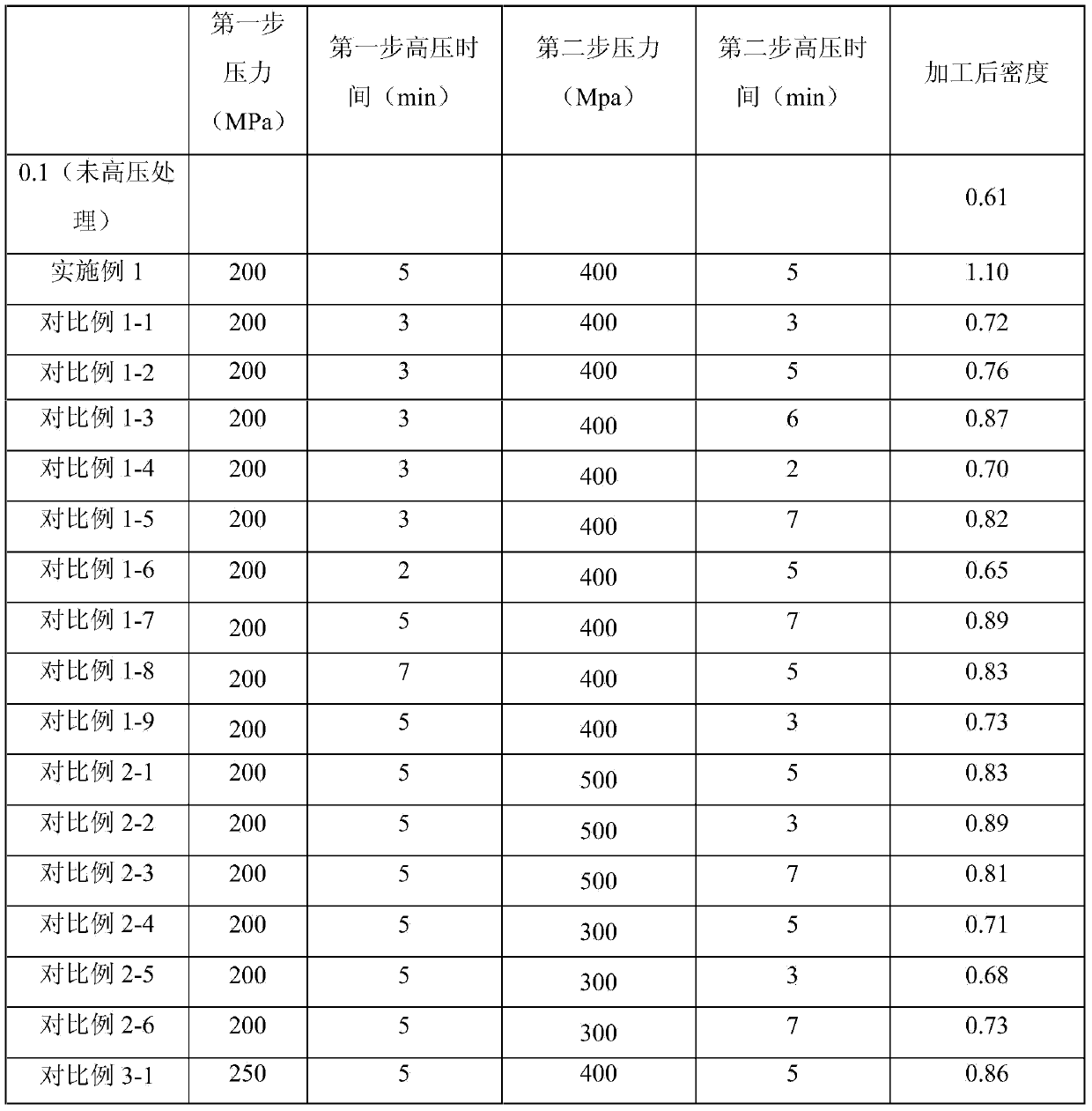

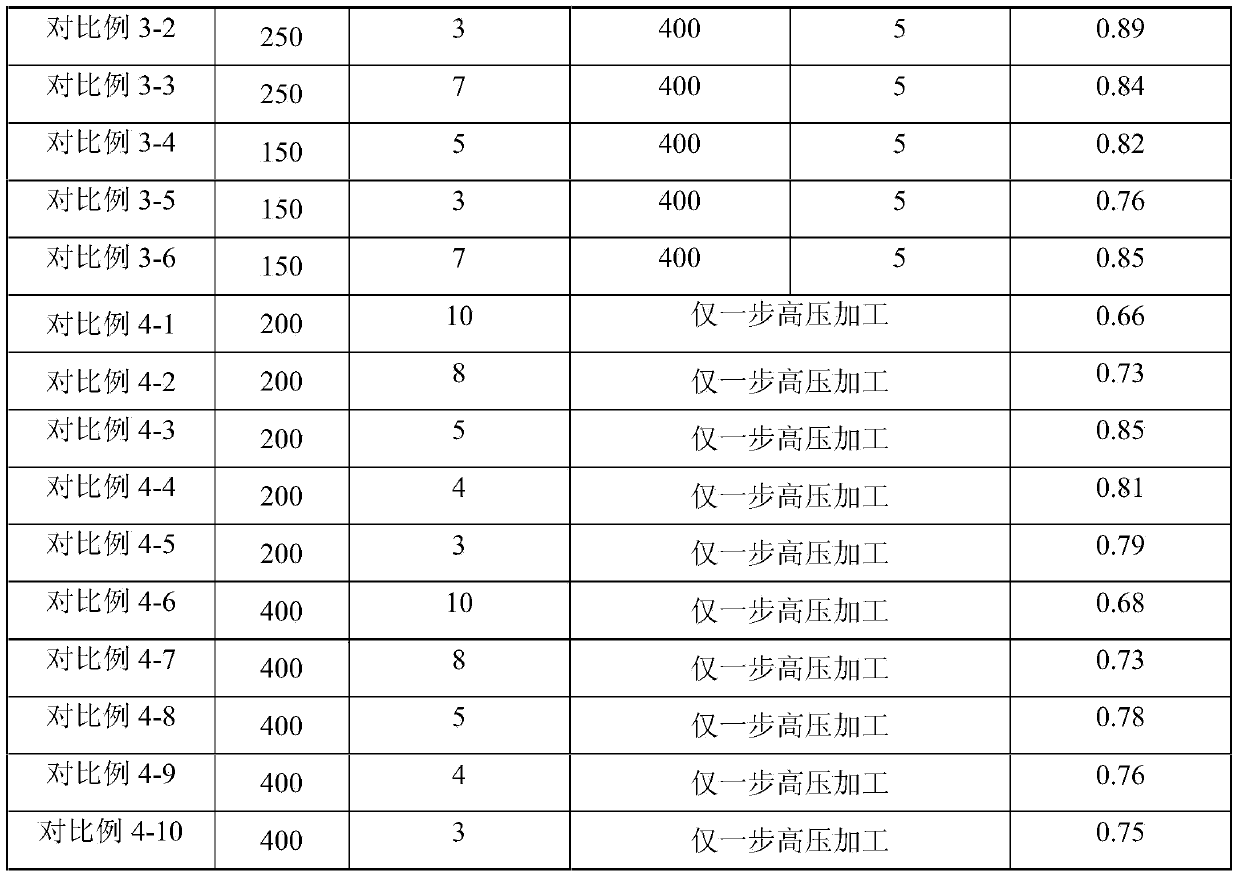

Embodiment 1

[0022] Select artificial forest fir wood with a diameter of less than 30cm (growth age: 25 years, diameter about 20-25cm) harvested in March 2013, wrap and seal the above artificial forest fir wood with polyethylene plastic film, and put it into In the ultra-high pressure processing container, it is firstly subjected to a high-pressure treatment at 200MPa for a 5-minute holding time, and immediately after the pressure is released, it is then subjected to a pressure treatment at 400Mpa for a 5-minute holding time, and then taken out after treatment. The volume and mass of the plantation fir wood before and after treatment were measured, and the density was calculated.

Embodiment 2

[0032] Embodiment 2, it is 25 years in the embodiment 1 that the artificial forest fir tree that the diameter is about 20~25cm is changed into the artificial forest fir wood that the growth year is 20 years, the diameter is about 13~16cm; All the other are the same as embodiment 1.

[0033] After the above treatment, the density of the artificial forest fir is changed from the original 0.59g / cm 3 increased to 1.12g / cm 3 .

Embodiment 3

[0034] Embodiment 3, it is 25 years that the growth period is 25 years in embodiment 1, and the artificial forest fir tree that diameter is about 20~25cm changes growth period into 30 years, and the plantation forest fir tree that diameter is about 25~29cm. All the other are with embodiment 1.

[0035] After the above treatment, the density is changed from the original 0.63g / cm 3 increased to 1.08g / cm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com