High temperature-resistant and salt-resistant fluid loss additive and preparation method thereof

A fluid loss reducer and high temperature resistant technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high quality requirements of workers, difficult operation and implementation, complicated processes, etc., and achieve cost reduction, filtration loss, etc. The effect of reducing volume and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

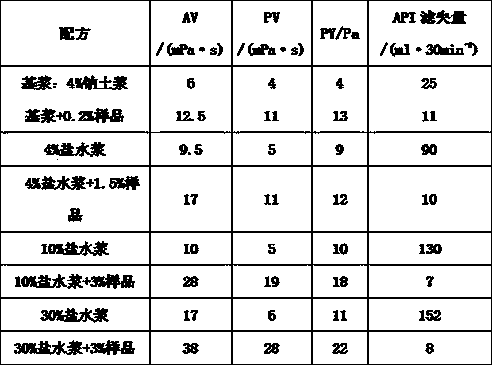

Examples

Embodiment 1

[0047] Take 20 parts of acrylic fiber waste silk and 16 parts of plant fiber in the reactor, prepare 16 parts of sodium hydroxide and 120 parts of water to make lye of corresponding concentration, add it into the reactor and stir evenly, heat up to 100-150°C and react for 2 hours After a period of time, add 6 parts of sulfomethylphenol-formaldehyde resin, stir evenly, and then raise the temperature to 100-150°C for 1 hour. Dry and pulverize the reacted mixture to 40-80 mesh powder.

Embodiment 2

[0049] Take 10 parts of acrylic waste silk and 10 parts of plant fiber in the reactor, prepare 7 parts of sodium hydroxide and 60 parts of water to make lye of corresponding concentration, add it into the reactor and stir evenly, heat up to 100-150°C and react for 2 hours After a period of time, add 6 parts of sulfomethylphenol-formaldehyde resin, stir evenly, and then raise the temperature to 100-150°C for 1 hour. Dry and pulverize the reacted mixture to 40-80 mesh powder.

Embodiment 3

[0051] Take 15 parts of acrylic waste silk and 13 parts of plant fiber in the reactor, prepare 10 parts of sodium hydroxide and 100 parts of water to make lye with corresponding concentration, add it into the reactor and stir evenly, heat up to 100-150°C and react for 2 hours After a period of time, add 10 parts of sulfomethylphenol-formaldehyde resin, stir evenly, and heat up to 100-150°C for 1 hour. Dry and pulverize the reacted mixture to 40-80 mesh powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com