Copper-nickel-silicon alloy and preparation method thereof

A technology of silicon alloy and copper alloy, which is applied in the field of copper-nickel-silicon alloy and its preparation, can solve the problems of core and cavity production, insufficient strength, and inability to use injection molds, etc., to improve fatigue and wear resistance The effect of improving properties such as tensile strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

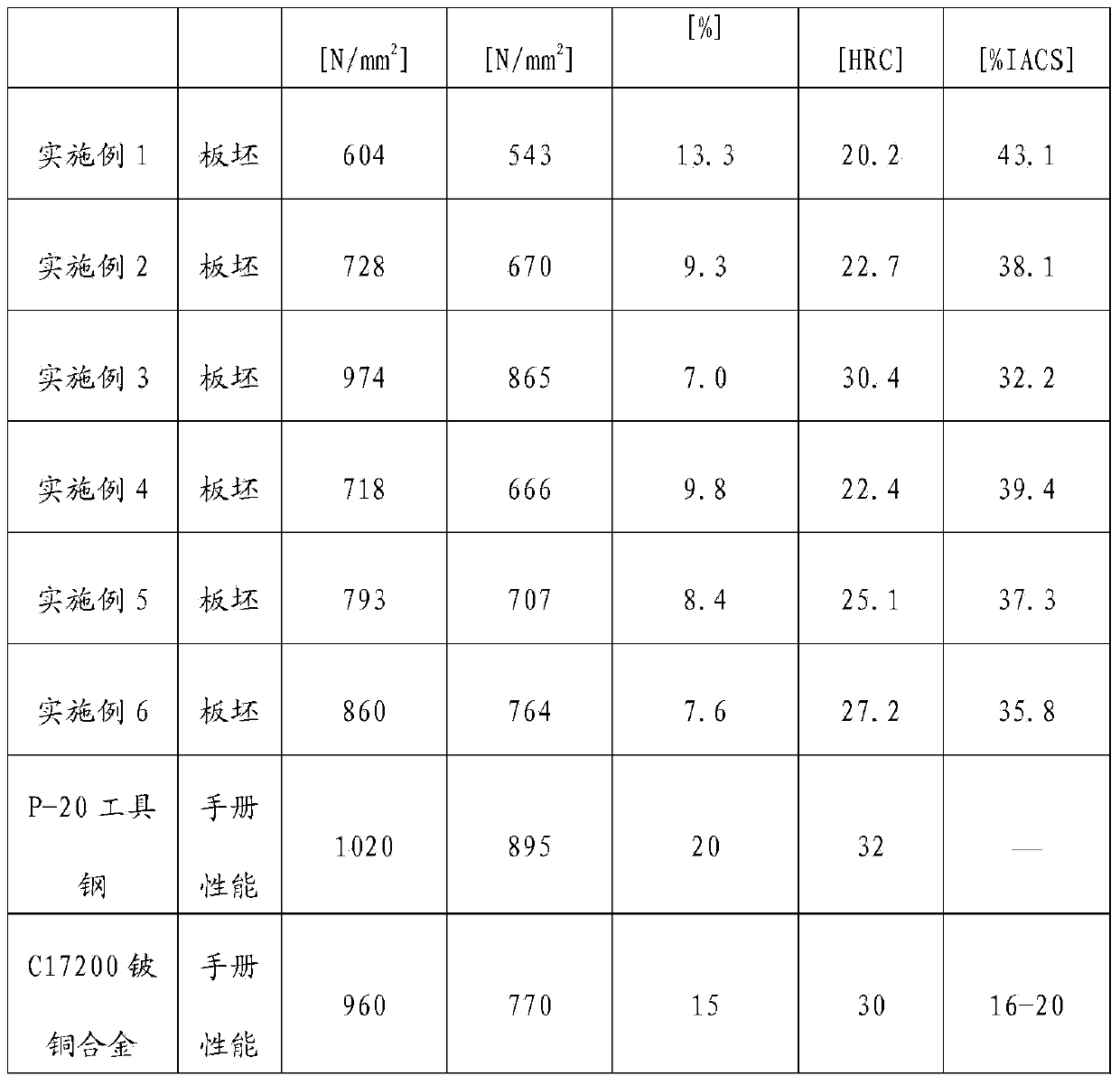

Embodiment 1

[0020] Based on the percentage of the total weight of the copper-nickel-silicon alloy: nickel accounts for 6%, silicon accounts for 1.5%, chromium accounts for 1.2%, manganese accounts for 0.4%, silver accounts for 0.08%, lithium accounts for 0.06%, and copper accounts for 90.76%.

[0021] Preparation method: put copper, nickel and silicon into a vacuum melting furnace, after melting, add chromium, manganese, silver and lithium, after melting, pour into alloy ingots; hot forge the obtained alloy ingots in turn ( The initial forging temperature is 940°C, the final forging is 700°C), solid solution (940°C, 2h), aging (450°C, 8h) treatment processes, and the 450×540×140mm, about 300kg heavy slab is produced.

Embodiment 2

[0023] Based on the percentage of the total weight of the copper-nickel-silicon alloy: nickel accounts for 6.5%, silicon accounts for 1.8%, chromium accounts for 0.8%, manganese accounts for 0.3%, silver accounts for 0.06%, lithium accounts for 0.08%, and copper accounts for 90.46%.

[0024] Preparation method: put copper, nickel and silicon into a vacuum melting furnace, after melting, add chromium, manganese, silver and lithium, after melting, pour into alloy ingots; hot forge the obtained alloy ingots in turn ( The initial forging temperature is 940°C, the final forging is 700°C), solid solution (960°C, 2h), and aging (460°C, 6h) treatment processes to produce a 450×540×140mm, about 300kg heavy slab.

Embodiment 3

[0026] Based on the percentage of the total weight of the copper-nickel-silicon alloy: nickel accounts for 7%, silicon accounts for 2%, chromium accounts for 0.7%, manganese accounts for 0.2%, silver accounts for 0.05%, lithium accounts for 0.06%, and copper accounts for 89.99%.

[0027] Preparation method: put copper, nickel and silicon into a vacuum melting furnace, after melting, add chromium, manganese, silver and lithium, after melting, pour into alloy ingots; hot forge the obtained alloy ingots in turn ( The initial forging temperature is 940°C, the final forging is 700°C), solid solution (970°C, 2h), and aging (470°C, 4h) treatment processes to produce a 450×540×40mm, about 87kg heavy slab.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com