Imitation ceramic wallboard coated with ultraviolet resistant coating and preparation method of imitation ceramic wallboard

A technology of anti-ultraviolet coating and imitation ceramics, which is applied in covering/lining, building, building structure, etc., can solve the problems of complex operation, long construction period, and complicated process, and achieve low process cost, easy operation, and preparation process Simple and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

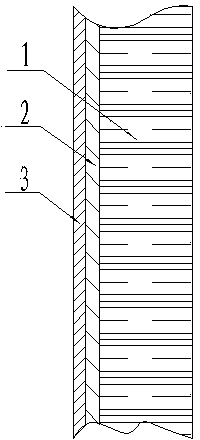

[0028] A ceramic imitation wallboard coated with an anti-ultraviolet coating, which includes an imitation ceramic base 1, an imitation ceramic forming layer 2 and an anti-ultraviolet coating 3, the outer surface of the imitation ceramic base 1 contains a ceramic imitation forming layer 2, and the imitation ceramic molding A layer of anti-ultraviolet coating 3 is sprayed on the layer 2;

[0029] The imitation ceramic molding layer 2 is an imitation exterior wall tile texture layer; the anti-ultraviolet coating 3 is a commercially available anti-ultraviolet paint; the imitation ceramic base layer 1 is composed of 50% (weight) coal gangue fiber particles , 35% (weight) polymer fire-resistant modified material, 10% (weight) silicon-aluminum clinker and 5% (weight) stearic acid are mixed and then added with pigments imitating the color of ceramic tiles.

[0030] A preparation method for an anti-ultraviolet coating imitation ceramic wallboard, comprising the following steps:

[003...

Embodiment 2

[0038] A ceramic imitation wallboard coated with an anti-ultraviolet coating, which includes an imitation ceramic base 1, an imitation ceramic forming layer 2 and an anti-ultraviolet coating 3, the outer surface of the imitation ceramic base 1 contains a ceramic imitation forming layer 2, and the imitation ceramic molding A layer of anti-ultraviolet coating 3 is sprayed on the layer 2;

[0039] The imitation ceramic molding layer 2 is an imitation tile texture layer; the anti-ultraviolet coating 3 is a commercially available anti-ultraviolet paint; the imitation ceramic base layer 1 is composed of 75% (weight) coal gangue fiber particles , 15% (weight) polymer fire-resistant modified material, 8% (weight) silicon-aluminum clinker and 2% (weight) stearic acid are mixed and then added with pigments imitating the color of ceramic tiles.

[0040] A preparation method for an anti-ultraviolet coating imitation ceramic wallboard, comprising the following steps:

[0041] (1) 75% (wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com