Device and method for sealing hole by using returned slag of layer-through drill hole of low drainage roadway of coal mine

A layer-penetrating drilling and coal mine technology, applied in safety devices, mining equipment, earthwork drilling, etc., can solve the problems of high labor intensity, lack of mature standards, cumbersome sealing process, etc., and achieve saving of sealing materials, Excellent sealing performance, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

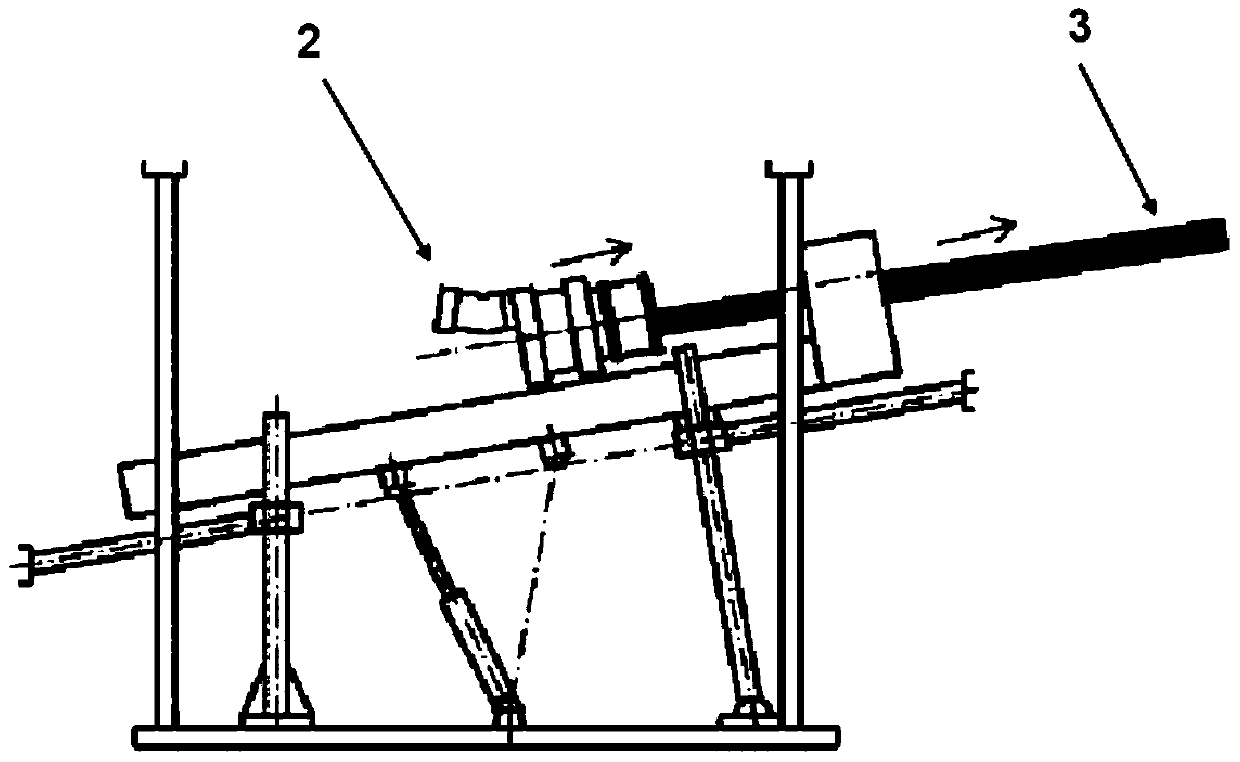

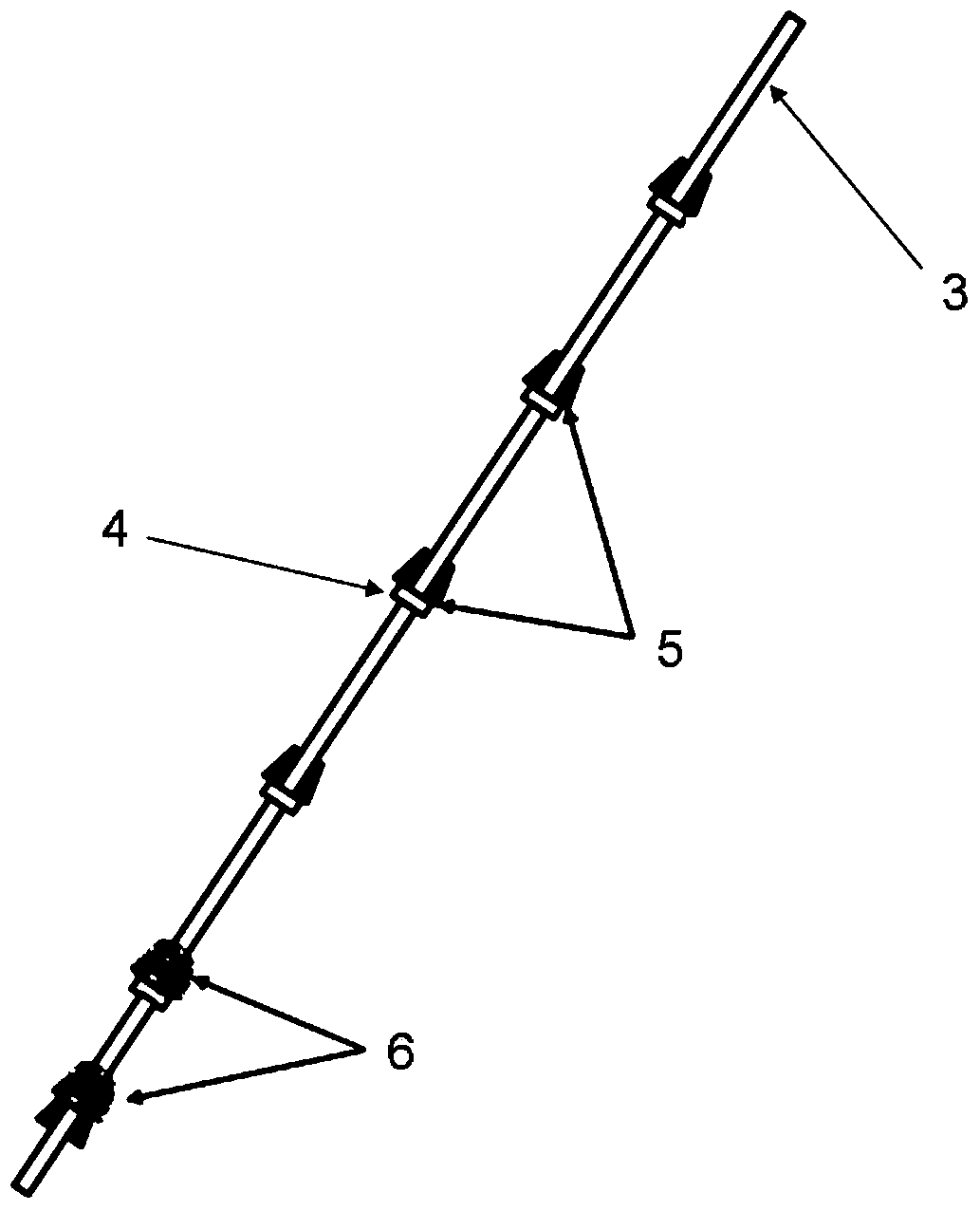

[0039] The present invention will be further described below through specific embodiments and accompanying drawings.

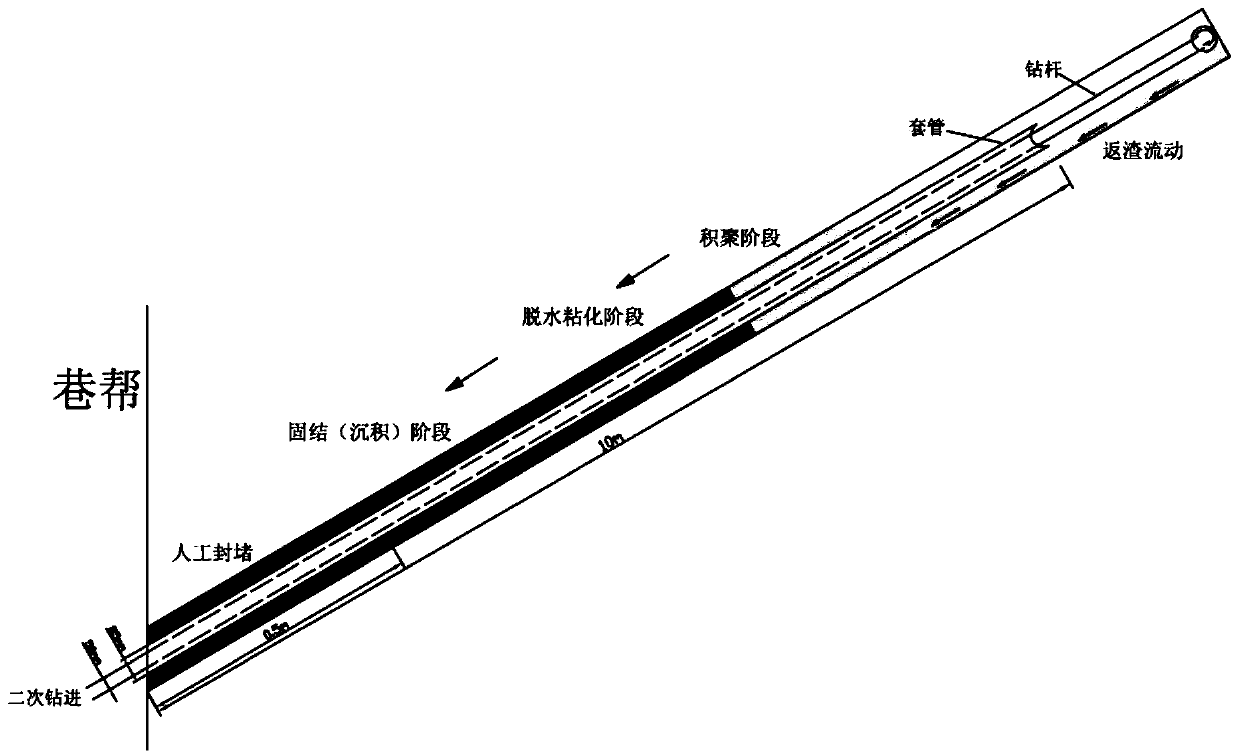

[0040] 1. The principle of hole sealing technology for drilling through layers in coal and rock formations.

[0041] After the overlying rock or coal seam (the drilling process is to drill the rock layer first, and finally pass through the coal seam), after being drilled and broken, it will form various water contents of gravel, cuttings or their mixture, under the influence of water flow and oblique gravity. Under the combined action, a continuous movement similar to flow is produced along the slope of the inner wall of the borehole at various speeds.

[0042] In the present invention, these backflow cuttings are called "return slag", and these backflow slag are used to seal the drilled holes through layers. The specific process principle is as follows: figure 1 Shown: When the water content reaches 80%, through process improvement, these backflow cuttings, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com