Laser heterodyne interferometry method and device for diagonal incident light based on corner cube

A technology of laser heterodyne interference and corner cube prism, which is applied in the field of laser applications, can solve the problems that cannot meet the requirements of high precision and resolution of interferometers, limit the development of ultra-precision machining and measurement fields, and be easily affected by ambient temperature. Achieve the effects of adjustment difficulty and high processing cost, eliminate temperature drift, and reduce adjustment difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

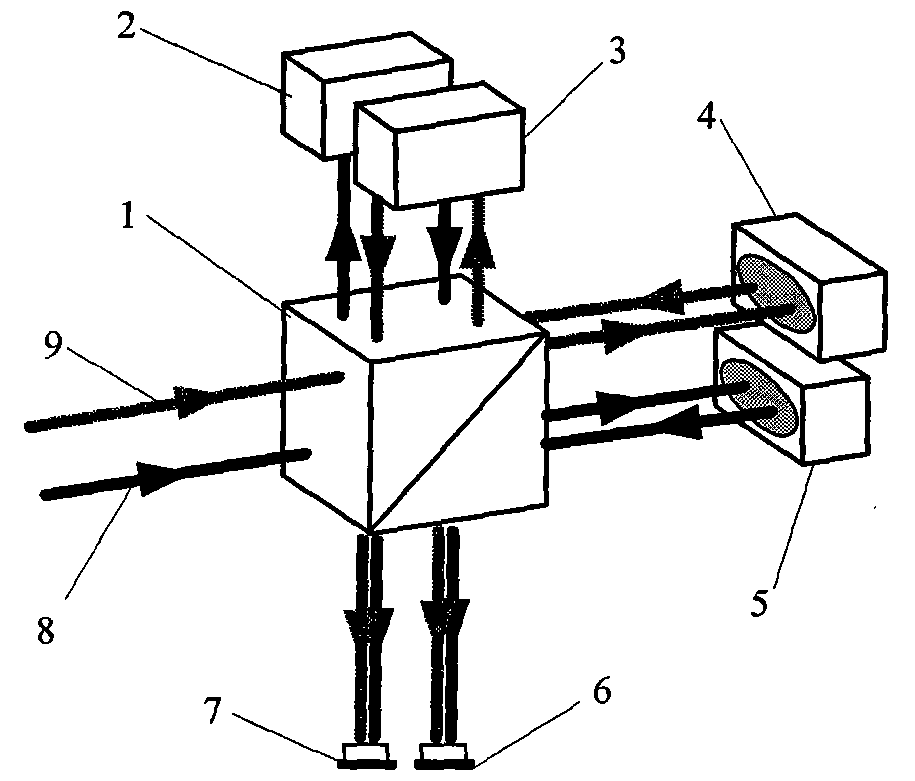

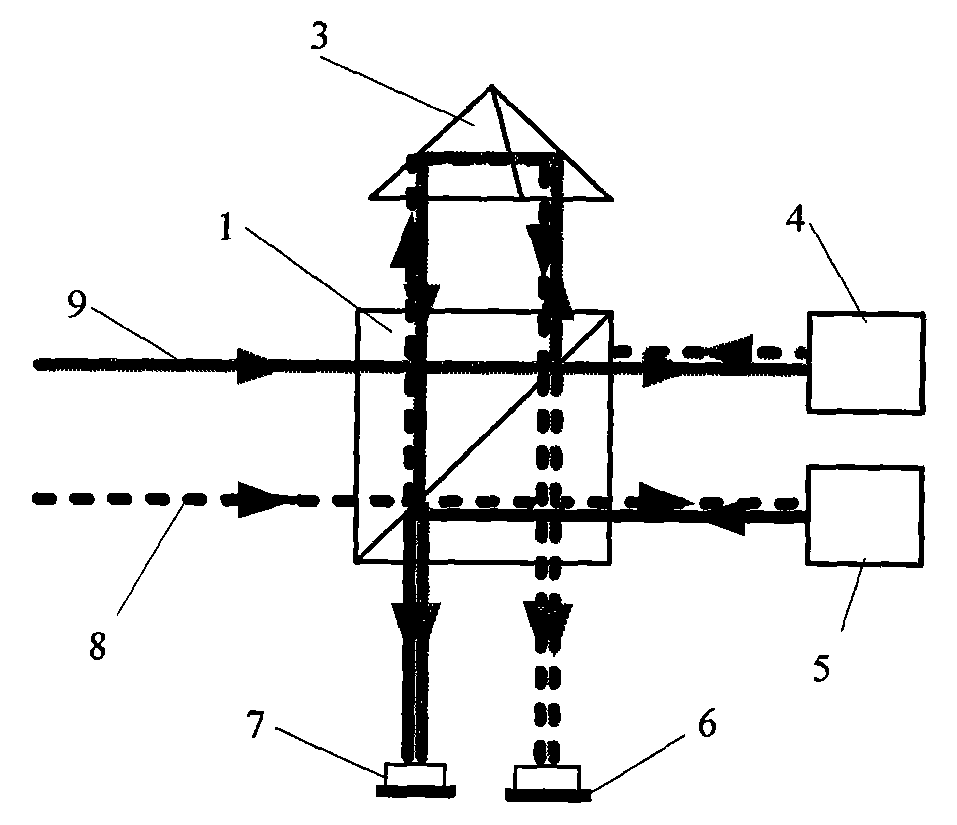

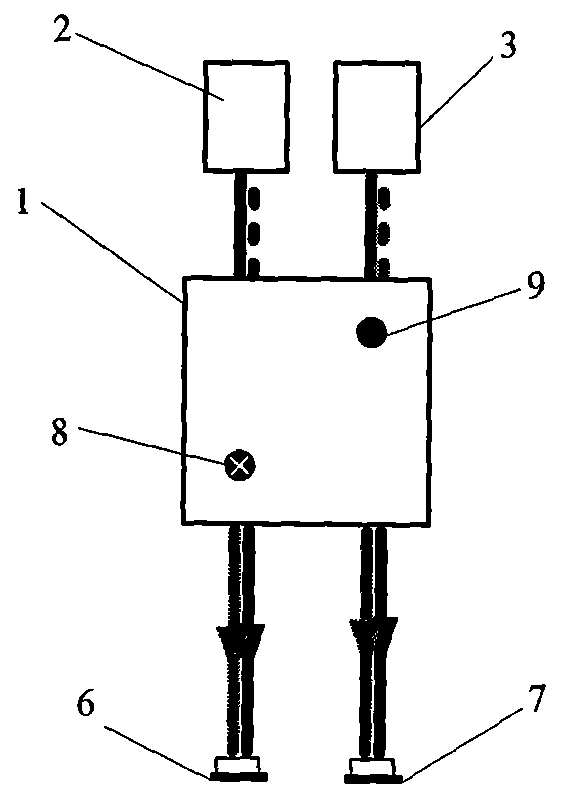

[0026] The examples of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] A kind of diagonal incident light laser heterodyne interferometry device based on corner cube prism, this device comprises non-polarizing beam splitting prism 1, photodetector A6, photodetector B7; The incident point is located at the diagonal position of the incident surface, and the non-polarizing beamsplitter prism 1 outputs two interferometric beams, one of which is connected to the photodetector A6, and the other interferometric beam is connected to the photodetector B7; the device also includes a fixed angle Cube prism A3, fixed corner cube prism B2, target end corner cube prism C4 and target side corner cube prism D5; Described fixed corner cube prism A3 and fixed corner cube prism B2 are positioned at non-polarizing beam splitter 1 reflected light output end, target end The corner cube C4 and the target corner cube D5 are located at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com