Wooden material grinding force determining method

A measurement method and technology of grinding force, which is applied in the field of wood processing, can solve the problems that the grinding force is not accurate enough, does not have real-time performance, and cannot reflect the changing trend of grinding force, etc., and achieves simple and strong accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] The invention provides a method for measuring the grinding force of wood materials. The testing machine used in the method is a single sand frame contact roller sander, the contact roller is a spiral groove rubber roller, and the Shore hardness is 25. The grinding thickness accuracy of the testing machine is 0.05mm. Measuring instruments include: KISTLER-3257A sensor, KISTLER5806 charge amplifier, NEC OmniaceⅡRA2300 signal analyzer.

[0028] The material used is poplar wood with a density of 0.44g / cm 3 , the grinding direction is perpendicular to the grain direction. The length of the test piece is 150mm and the width is 100mm. The model of the abrasive belt is CXB-508, and the abrasive grains are electrostatically planted.

[0029] Grinding conditions: the mesh number of the abrasive belt is 60 mesh; the belt speed is 5.35m / s; the feed speed is 5.14m / s; the grinding thickness is 0.2mm.

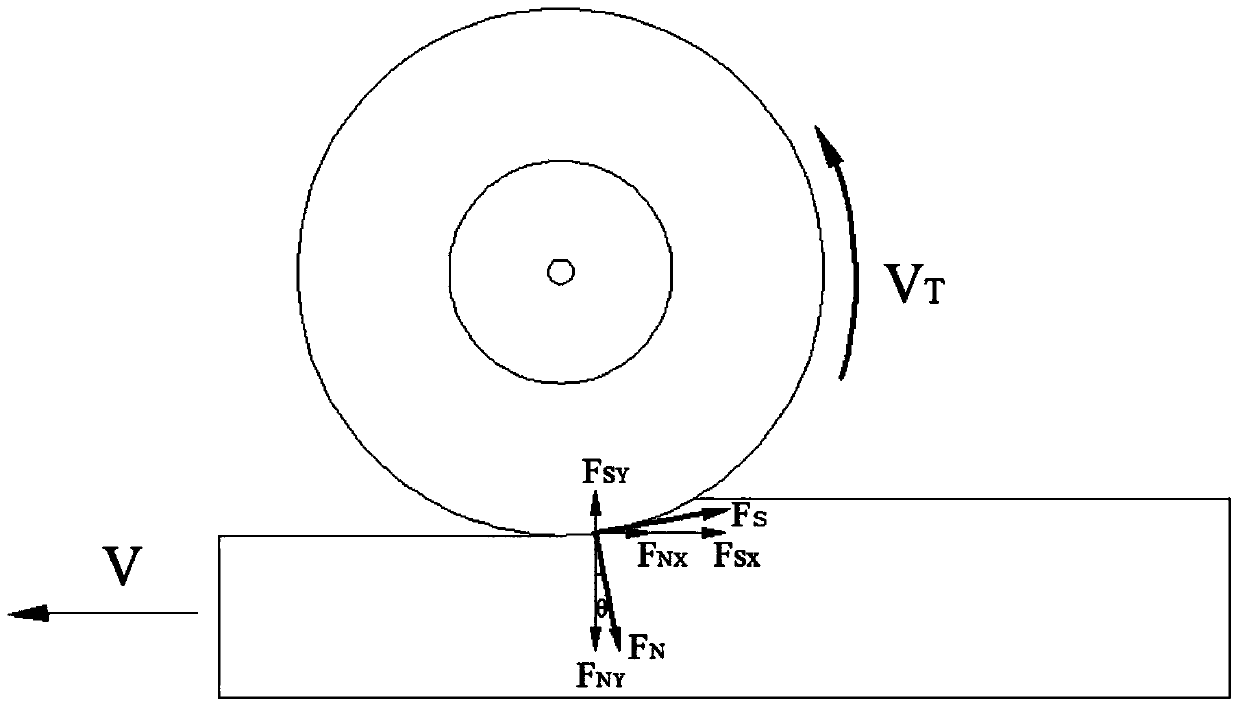

[0030] The determination method includes the following steps: firstly, the rel...

example 2

[0047] The equipment, instrument, calibration method and calibration results used in the determination process are all the same as in Example 1.

[0048] The material used is medium density fiberboard with a density of 0.741g / cm 3 . The length of the test piece is 150mm and the width is 100mm. The model of the abrasive belt is CXB-508, and the abrasive grains are electrostatically planted.

[0049]Grinding conditions: the mesh number of the abrasive belt is 80 mesh; the belt speed is 5.35m / s; the feed speed is 3.71m / s; the grinding thickness is 0.5mm.

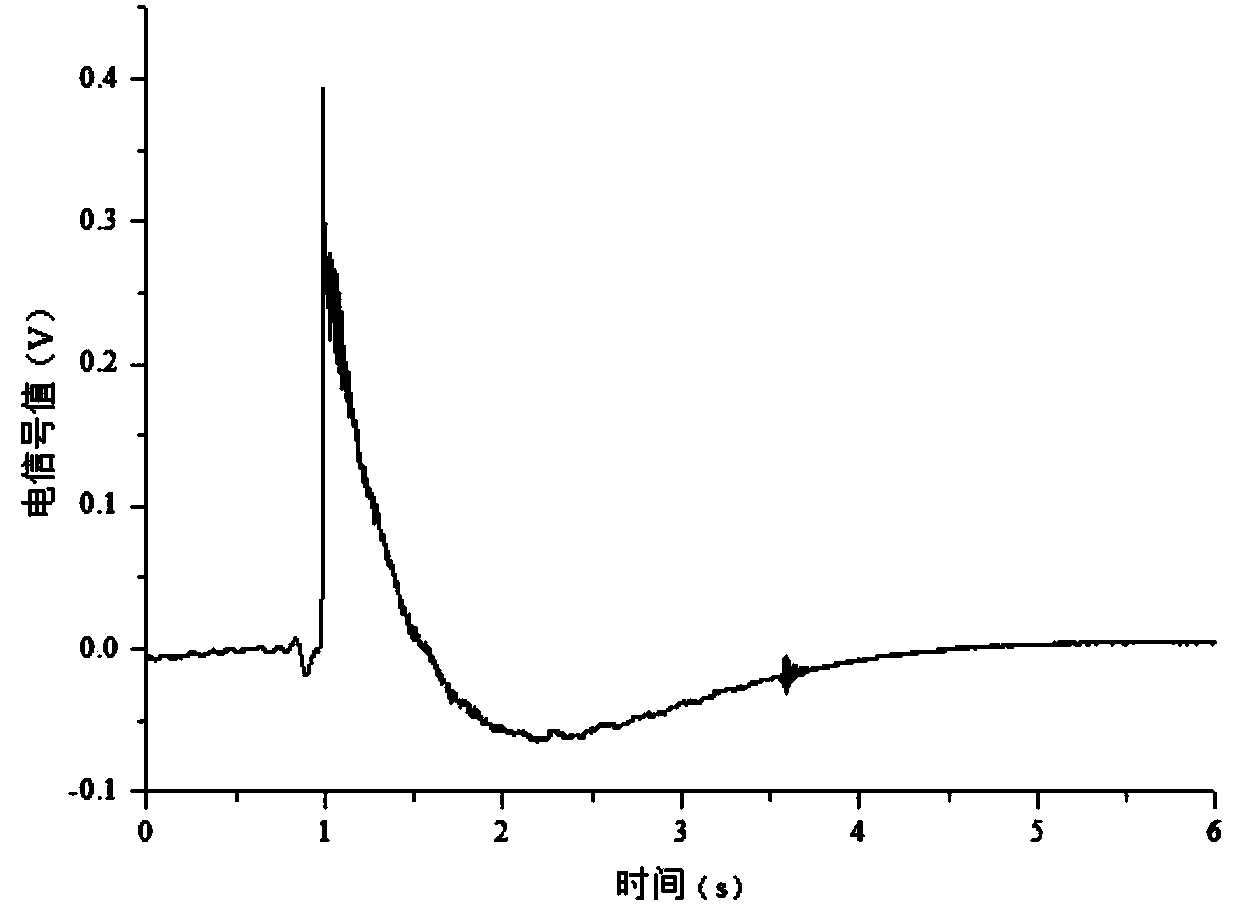

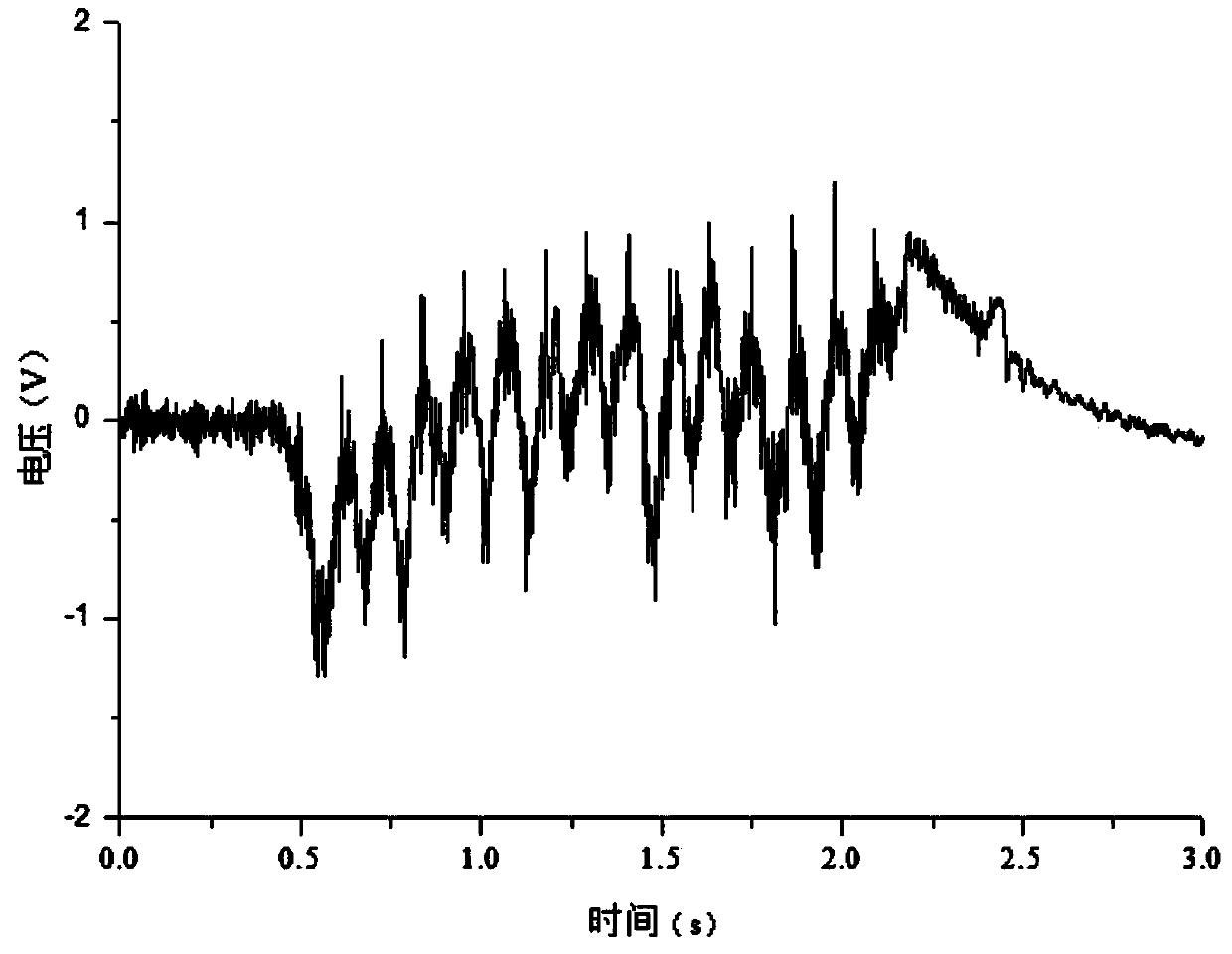

[0050] Figure 9 The curve diagram of the grinding force and electricity signal in the grinding process, Figure 10 In order to remove clutter and remove the abrasive belt without touching the workpiece and after the abrasive belt and the workpiece are separated, the post-wave grinding force and electrical signal curve. Because the calibration direction is opposite to the grinding force direction, the electrical signal val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com