Small-sized rocket engine test bed spray device

A technology of spraying device and engine, applied in the direction of engine test, measurement device, machine/structural component test, etc., can solve problems such as large impact, impact on facility and operator safety, etc., to enhance heat exchange effect and facilitate recovery The effect of low process and equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

[0020] The invention is a spray device designed for a small engine test bench, which mainly realizes the functions of draining the exhaust flame of the engine and spraying to reduce temperature and noise.

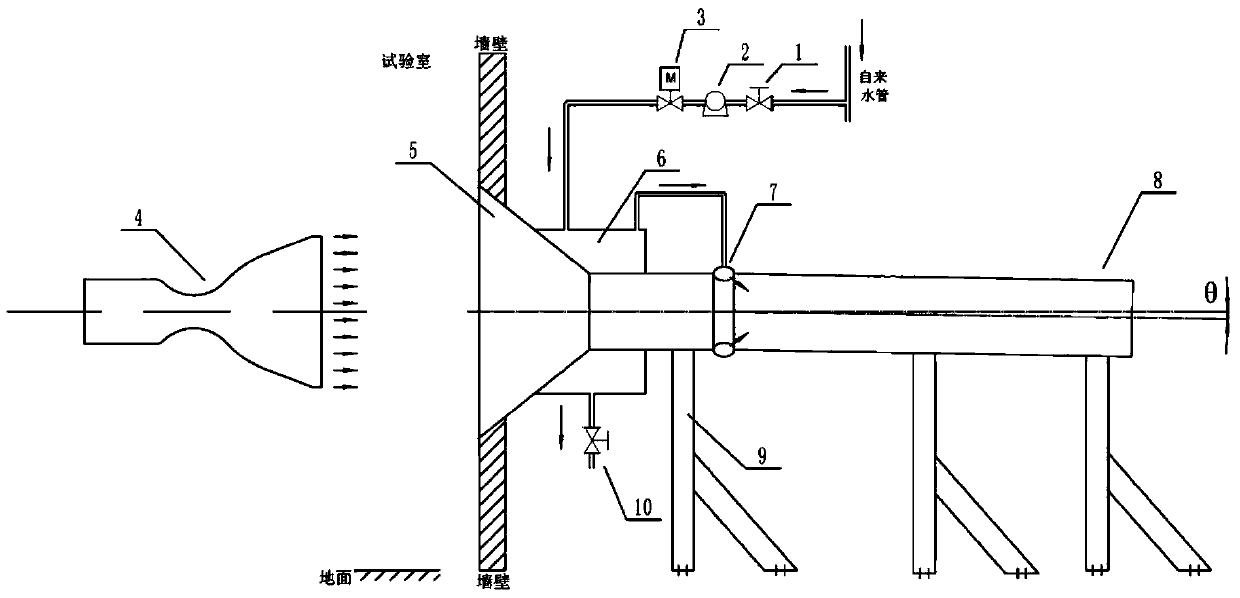

[0021] Such as figure 1 As shown, the sprinkler device includes a water supply system and an engine exhaust drainage system.

[0022] The water supply system includes a manual shut-off valve 1 , a booster pump 2 , a solenoid valve 3 , a water tank 6 , a spray ring 7 and a manual shut-off valve 10 .

[0023] The two ends of the manual shut-off valve 1 are respectively connected to the tap water pipe in the laboratory and the booster pump 2, and the two ends of the solenoid valve 3 are respectively connected to the booster pump 2 and the inlet of the water tank 6. The water tank 6 is provided with two outlets, one is connected to the spray ring 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com