Micromechanical sensor with three-layer substrate

A technology of micromechanical sensors and substrates, which is applied in scientific instruments, measuring devices, meteorology, etc., can solve the problems of incompatibility of production process microelectronics process, difficulty in large-scale use, and measurement impact, so as to achieve easy control of process quality and low cost. Low, volume-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

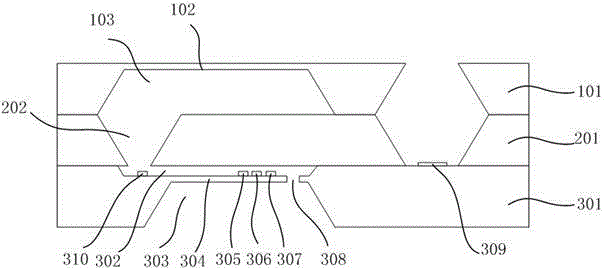

[0020] Such as figure 1 The shown micromechanical sensor with a three-layer substrate includes: a first substrate 101 made of a single crystal silicon wafer, a second substrate 201, and a third substrate 301, and the third substrate 301 is a micromechanical sensor with a three-layer substrate. The base, the second substrate 201 is placed on the third substrate 301 and connected to the third substrate 301 , the first substrate 101 is placed on the second substrate 201 and connected to the second substrate 201 .

[0021] The first substrate 101 is processed by a MEMS process to obtain a first cavity 103 with an opening downward and a first membrane 102 .

[0022] The second substrate 201 is opened with a first through hole 202 , and the first through hole 202 communicates with the first cavity 103 .

[0023] The third substrate 301 is processed by the MEMS process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com