Tunnel type sterilization oven heating monitoring control system and method

A sterilizing oven and control system technology, applied in the direction of control/regulation system, temperature control, non-electric variable control, etc., can solve the problems of hidden dangers in production safety, complicated wiring, high production requirements, etc., to achieve stable production and operation, avoid hidden dangers, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

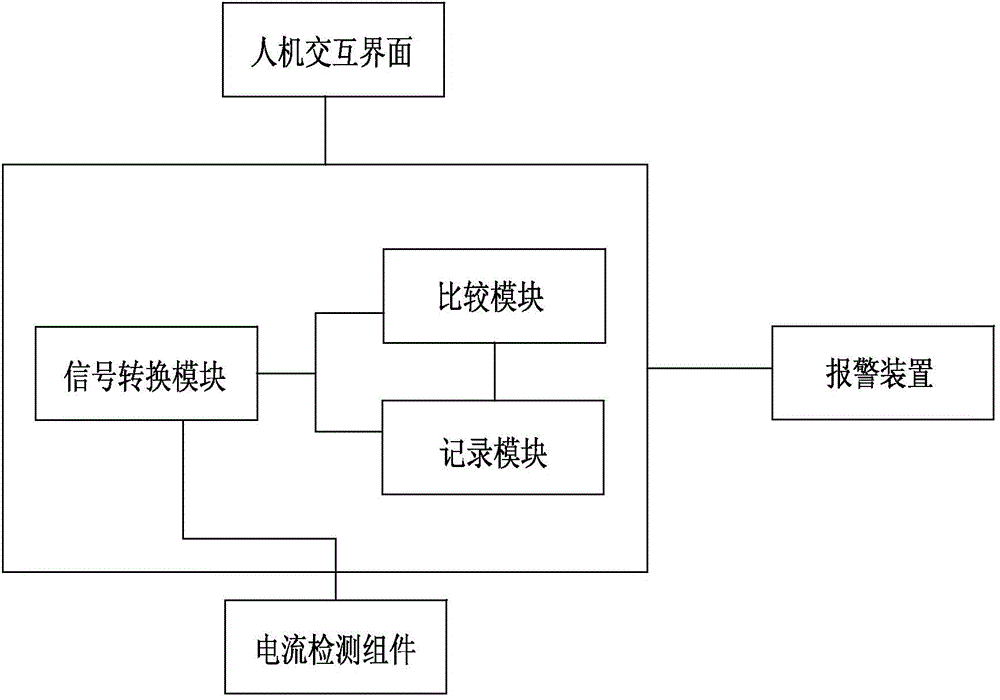

[0019] Such as figure 1 As shown, the tunnel-type sterilization oven heating monitoring control system of the present invention includes a controller, the controller is connected to a human-computer interaction interface, a current detection component and an alarm device, the human-computer interaction interface adopts a touch screen or a tablet computer, and the current detection component It is a current sensor mounted on the heating wire.

[0020] The controller includes a comparison module, a recording module, a signal conversion module and peripheral circuits, the current detection component is connected to the signal conversion module, and the signal conversion module is connected to the comparison module and the recording module.

[0021] The heating monitoring and control method of the tunnel type sterilization oven comprises the following steps:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com