Power supply circuit, control circuit for heating device and heating device

A technology of power supply circuit and control circuit, applied in induction heating control, induction heating, output power conversion device and other directions, can solve the problems of life reduction of working devices, fluctuation and damage of rectified output voltage, and achieve stable voltage and stable working voltage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0065] like Figure 9 and Figure 10 As shown, when the power supply circuit 700 is applied to the circuit of the electromagnetic heating device, and the control circuit of the electromagnetic heating device adopts a transistor (that is, a single-tube solution), the connection mode of the circuit is: the output of the anti-interference circuit 702 is connected to the rectifier circuit The input terminal of 704, the output terminal of the rectifier circuit 704 is connected to the input terminal of the filter circuit 706, the first filter circuit 706 includes capacitors C31, C32 and inductor L31, the capacitors C31, C32 and inductor L31 form a Π-type filter, and simultaneously connected in series Resistors R31, R32 and R33 can also be used as a discharge circuit for the post-rectification stage at no-load. One end of the resistors is connected to the output end of the rectifier bridge, and the other end is grounded for discharge. The buck-boost circuit 708 is composed of an ind...

Embodiment approach 2

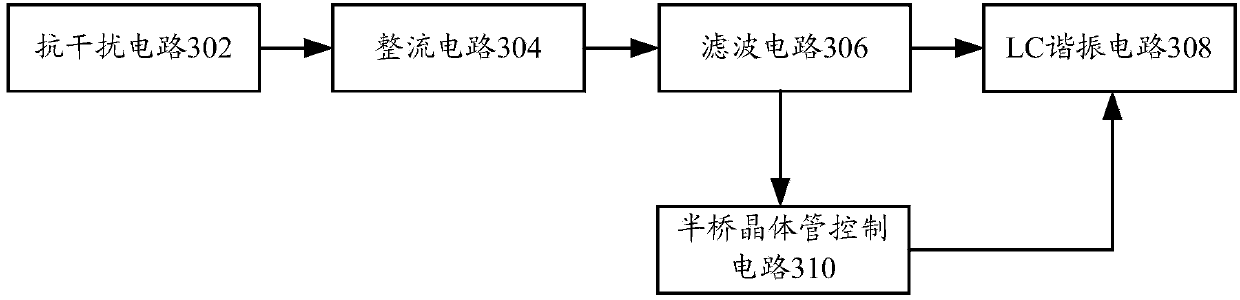

[0069] like Figure 11 and Figure 12 As shown, when the power supply circuit 700 is applied to the circuit of the electromagnetic heating device, and the control circuit of the electromagnetic heating device adopts two transistors (i.e. the half-bridge scheme), the connection mode of the circuit is: the buck-boost circuit 708 and the implementation mode One is the same, the output of the buck-boost circuit 708 is filtered by C51 and C52 of the second filter circuit 1108, and then connected to one end of C71 and C72 of the resonant circuit 1102, and connected to the C pole of IGBT61 and the E pole of IGBT62 of the control circuit 1104 . The control circuit 1104 includes IGBT61, IGBT62, C61 and C62, and C61 and C62 are used as the absorbing capacitance of the C pole of the IGBT to reduce the impact of high-frequency current on the IGBT61 and IGBT62. The resonant circuit 1102 includes resonant inductors L71, C71 and C72, C71 and C72 is a resonant capacitor, wherein the resonan...

Embodiment approach 3

[0071] like Figure 14 and Figure 15 As shown, when the power supply circuit 700 is applied to the circuit of the electromagnetic heating device, and the control circuit of the electromagnetic heating device adopts four transistors (that is, the full-bridge scheme), the connection mode of the circuit is: the front-stage part circuit of the full-bridge scheme (i.e. the power supply circuit 700) is the same as the circuit in the second embodiment, the output of the second filter circuit 1408 is connected to both ends of multiple control circuits 1404 (i.e. the control circuit 14042 and the control circuit 14044), that is, respectively connected to the C poles of the IGBT61 , the E pole of IGBT62, the C pole of IGBT71 and the E pole of IGBT72, the control circuit 14042 includes IGBT61, IGBT62, C61, C62, R61 and R62, C61, C62, R61 and R62 as IGBT interference absorption circuit components, IGBT control circuit 14044 Including IGBT71, IGBT72, C71, C72, R71 and R72, C71, C72, R71 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com