Method for flotation of cobalt in fly ash

A fly ash and roughing technology, which is applied in flotation, solid separation, etc., can solve the problems that there are no relevant reports on the technology of extracting cobalt metal, and achieve the effects of high recovery rate, low energy consumption, and low flotation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

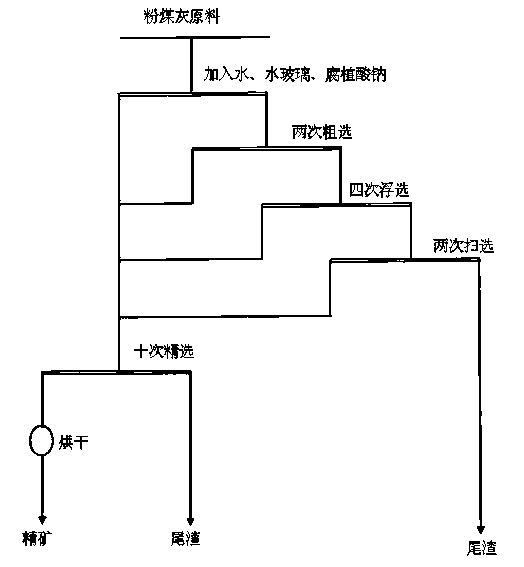

[0020] Example 1. Take 1 ton of fly ash and add 3 tons of water, stir evenly in a bucket, transfer to a reaction tank, add 500 grams of water glass, stir for 5 minutes, add 300 grams of sodium humate, operate at a temperature of 32 ° C, and soak for 3 Minutes, transfer to the roughing tank, add 300 grams of collector JR-7, operating temperature 15 ° C, soaking time 10 minutes, carry out two roughings, transfer to the static pressure cyclone flotation column, add 100 grams of foaming Agent EFY-9, the compressed air of 0.5Pa was passed through to float the collected cobalt, carried out four times of flotation, and transferred to the scavenging tank, after two times of scavenging, the tailings were discharged, and the two times of roughing, four times of cobalt After flotation and two times of sweeping, the cobalt-rich fly ash is combined and transferred to the beneficiation tank. After ten times of beneficiation, it is transferred to the drying room for drying. After drying, the ...

Embodiment 2

[0021] Example 2, take 1 ton of fly ash and add 3 tons of water, stir evenly in a bucket, transfer to a reaction tank, add 500 grams of water glass, stir for 3 minutes, add 300 grams of sodium humate, operate at a temperature of 15 ° C, and soak for 5 Minutes, transfer to the roughing tank, add 200 grams of collector JR-7, the operating temperature is 32 ° C, the soaking time is 5 minutes, carry out two roughings, transfer to the static pressure cyclone flotation column, add 150 grams of foaming Agent EFY-9, the compressed air of 0.8Pa was introduced to float the collected cobalt, carried out four times of flotation, and transferred to the scavenging tank, after two times of scavenging, the tailings were discharged, and the two times of roughing, four times of cobalt After flotation and two times of sweeping, the cobalt-rich fly ash is combined and transferred to the beneficiation tank. After ten times of beneficiation, it is transferred to the drying room for drying. After dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com