Roller detaching device

A dismantling device and roll technology, applied in metal rolling, metal rolling, metal rolling stands, etc., can solve the problems of increased spare parts consumption, difficulty in lifting heavy parts by crane, difficult disassembly and separation, etc., so as to improve the operation. Efficiency and equipment operation rate, reduction of spare parts consumption and expenses, and the effect of shortening disassembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

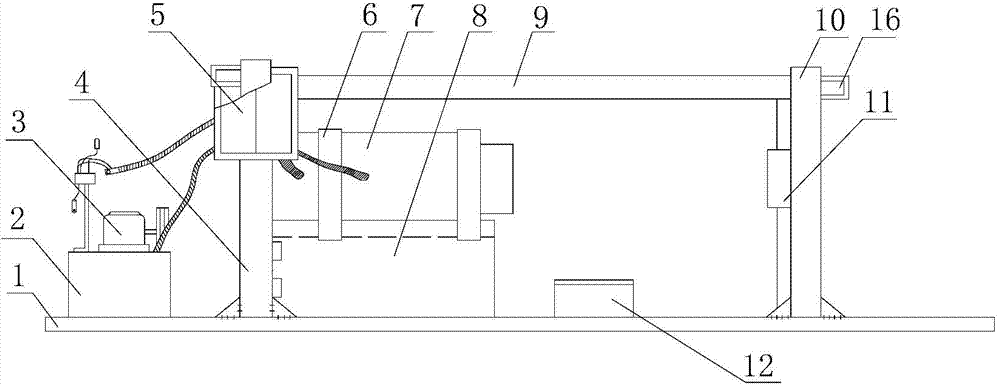

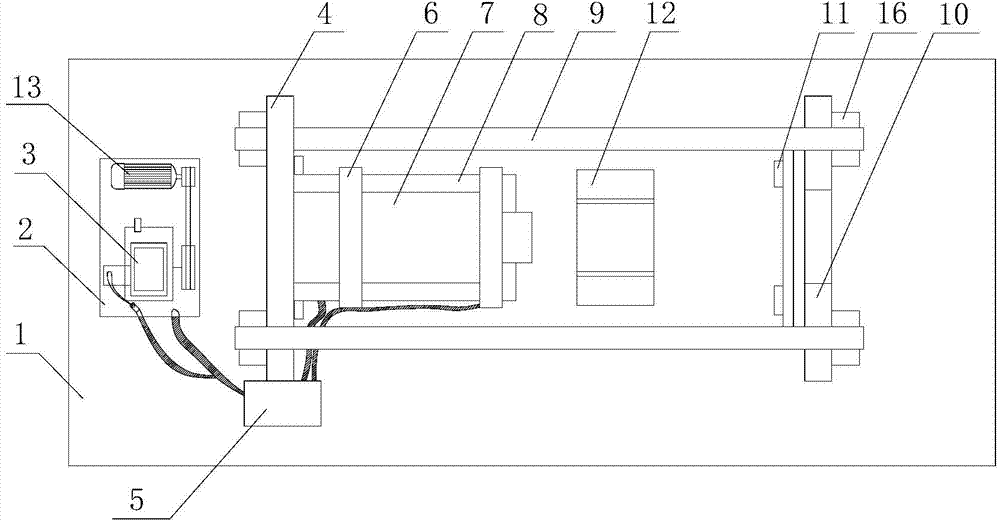

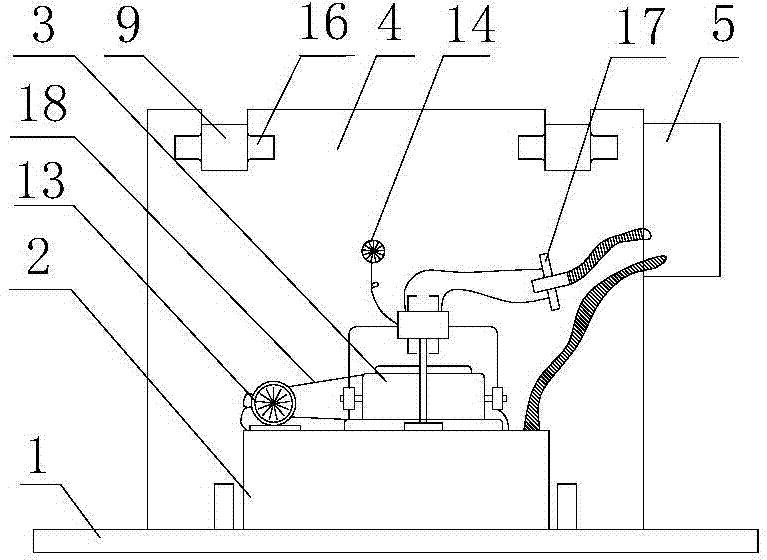

[0016] As can be seen from the accompanying drawings, the present invention is mainly composed of a base 1, a gear pump 3, a pallet 4, an electric control box 5, a clamp hoop 6, a support 8, a pull rod 9, a deck 10, an iron stop 11, a pad iron 12, a motor 13. It is composed of wedge iron 16, belt 18 and hydraulic system. The hydraulic system includes a fuel tank 2, a gear pump 3, a hydraulic cylinder 7, a pressure gauge 14, a manifold 15, an oil filter 17 and a reversing valve.

[0017] On the left side upper surface of the base 1, a card plate 4 is vertically welded, and a card holder 10 is vertically welded on the right upper surface, and a card slot is respectively opened on both sides of the upper end of the card plate 4 and the card holder 10, and the two pull rods 9 The end is clamped in the slot and fixed by wedge iron 16. The inner side of the clamping plate 4 is connected with a "V"-shaped support 8 by bolts, and a hydraulic cylinder 7 is fixed through the clamp 6 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com