Method for continuously producing high-cleanness silicon dioxide

A silicon dioxide and cleaning technology, which is applied in the direction of silicon oxide, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of toothpaste agglomeration, inability to effectively clean the tooth surface, poor stability, and uniformity, and achieve easy separation and wear values Low, consistent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

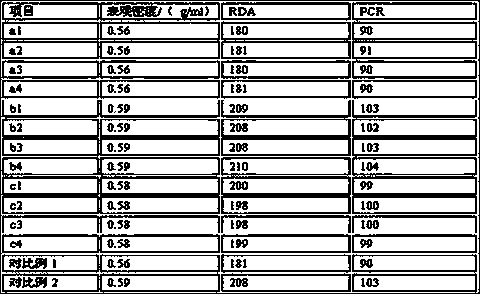

Examples

Embodiment 1

[0026] 1) In a 30m 3 The amount of substance added to the continuous reactor is a sodium sulfate solution whose concentration n0 is 0.5 mol / L, and the volume of sodium sulfate added is 10 m 3 ;

[0027] 2) Add a sodium silicate solution with a substance concentration n1 of 1mol / L in the continuous reactor, and adjust the pH value of the reaction solution to 8;

[0028] 3) Keep the reaction temperature at 60°C, and at the same time add a sodium silicate solution with a substance concentration n1 of 1mol / L and a sulfuric acid solution with a substance concentration n2 of 1mol / L, and the volume of the added sodium silicate solution is 8 000L , the volume of the added sulfuric acid solution is 8000L;

[0029] The sodium silicate solution was added at a rate of 3 m 3 / h, the adding speed of sulfuric acid solution is 3m 3 / h;

[0030] 4) A precipitate and solution with a volume of 16,000L is released from the outlet below the continuous reactor, and the obtained precipitate is ...

Embodiment 2

[0033] 1) In a 30m 3 The amount of substance added to the continuous reactor is a sodium sulfate solution whose concentration n0 is 1mol / L, and the volume of sodium sulfate added is 10 m 3 ;

[0034] 2) Add a sodium silicate solution with a substance concentration n1 of 1.5mol / L in the continuous reactor, and adjust the pH value of the reaction solution to 8;

[0035] 3) Keep the reaction temperature at 60°C, and simultaneously add a sodium silicate solution with a substance concentration n1 of 1.5 mol / L and a sulfuric acid solution with a substance concentration n2 of 3 mol / L, and the volume of the added sodium silicate solution is 8 000L, the volume of the added sulfuric acid solution is 4000L;

[0036] The sodium silicate solution was added at a rate of 3m 3 / h, the adding speed of sulfuric acid solution is 1.5m 3 / h;

[0037] 4) While step 3) is being carried out, a precipitate is formed in the reactor, and the mixture of the precipitate and the reaction solution is r...

Embodiment 3

[0040] 1) In a 30m 3 Add the sodium sulfate solution whose concentration n0 is 0.8mol / L in the continuous reactor, and the volume of sodium sulfate added is 10 m 3 ;

[0041] 2) Add a sodium silicate solution with a substance concentration n1 of 1.2mol / L in the continuous reactor, and adjust the pH value of the reaction solution to 8;

[0042] 3) Keep the reaction temperature at 60°C, and simultaneously add a sodium silicate solution with a substance concentration n1 of 1.2mol / L and a sulfuric acid solution with a substance concentration n2 of 2.4mol / L, and the volume of the added sodium silicate solution is 8 000L, the volume of the added sulfuric acid solution is 4000L;

[0043] The sodium silicate solution was added at a rate of 6 m 3 / h, the adding speed of sulfuric acid solution is 3m 3 / h;

[0044] 4) While step 3) is being carried out, a precipitate is formed in the reactor, and the mixture of the precipitate and the reaction solution is released from the outlet be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com