Synthetic method of high-selectivity comb-type CdS nanometer material

A nanomaterial, high-selectivity technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of rare reports of high-selectivity comb CdS nanomaterials, and achieve good repeatability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below are examples of the present invention (reagents used in the examples are all chemically pure), the main steps of the experimental process:

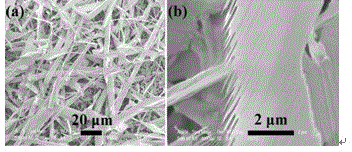

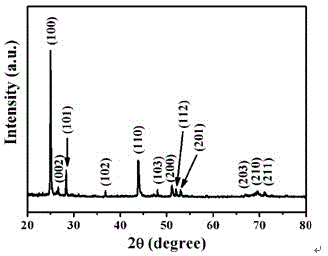

[0013] First, use a small ion sputtering device to coat a layer of Au film with a thickness of about 50 nm on a (100) crystal orientation Si substrate with a size of 0.9 cm*0.9 cm; put a ceramic boat containing 1.4 g of CdS powder into a quartz tube And push it to the position of the thermocouple of the tube furnace, push the Si substrate coated with Au film into the quartz tube to a position 17 cm away from the left side of the ceramic boat, seal the quartz tube, use a mechanical pump to pump air for 1 h, and then move it from the right Argon gas was introduced into the side at a flow rate of 30 sccm, and the gas flow rate of the gas inlet and outlet on both sides of the enamel was adjusted, and the air pressure in the quartz tube was maintained at 0.1 MPa by using a mechanical pump; under the protection of argon gas, the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com