Method for enriching beta-ethyoxyl rutinose

An ethoxylated rutose, enrichment technology, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

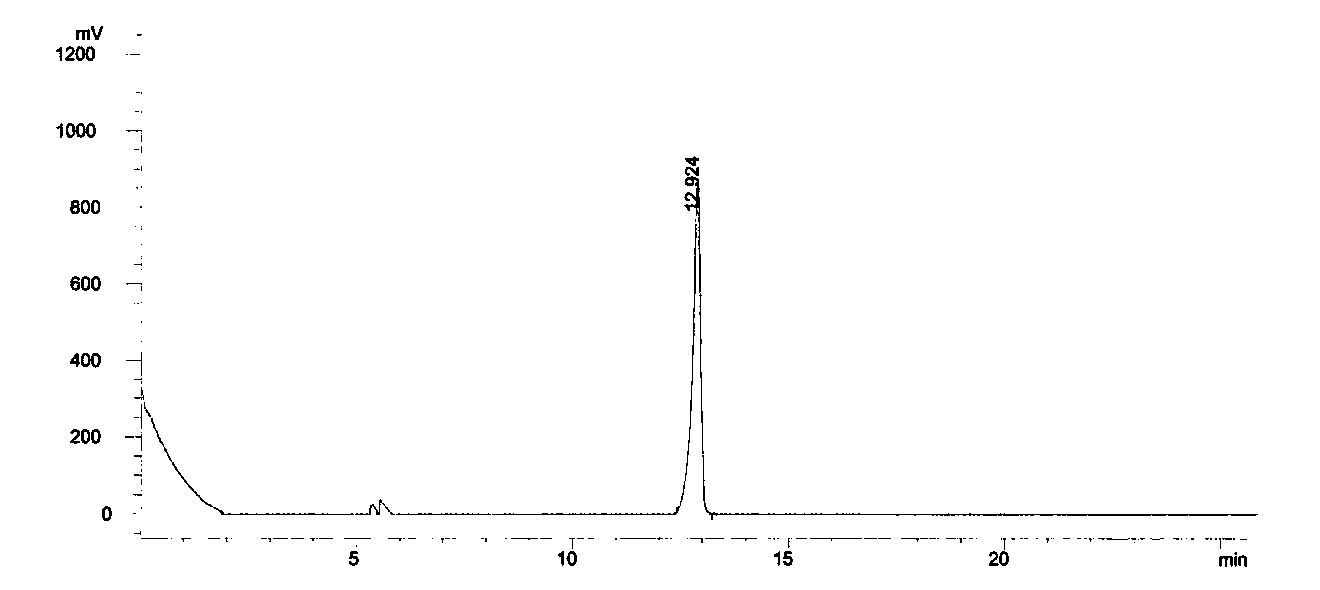

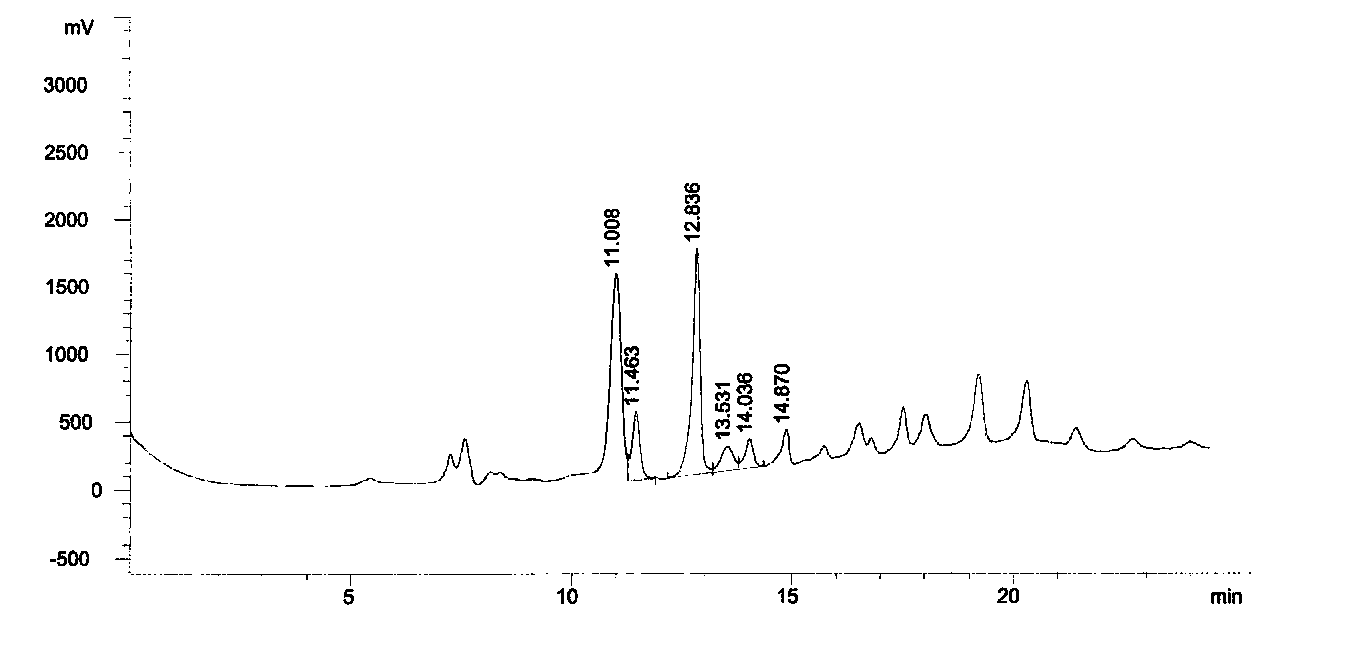

[0012] Put 10 kg of tartary buckwheat raw materials with high β-ethoxyrutinose content through enzymatic conversion into a 200-liter extraction tank, add 100 liters of 70% ethanol, extract at room temperature for 2 hours, and extract the residue once more. Combine the ethanol extracts to obtain 196 liters of filtrate, concentrate to 20 liters, then add 20 liters of deionized water, then pass through the macroporous resin column AB-8 (20 × 180 cm) column, first elute with 10 liters of deionized water, and then Eluted with 10 liters of 5% ethanol, then eluted with 20 liters of 10% ethanol, and then eluted with 90% ethanol. The 10% ethanol eluate was collected and concentrated under reduced pressure to obtain a concentrate of about 2 liters. Put 2 liters of macroporous resin 10% ethanol elution concentrate on MCI column chromatography (5×150cm), elute with 5 liters of deionized water, 5 liters of 10% and 5 liters of 20% ethanol respectively, and use thin layer For detection by ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com