Special emulsifier for water-based solid epoxy resin emulsion and preparation method of emulsion

A solid epoxy resin and epoxy resin technology, applied in the field of polymers, can solve the problems of high epoxy value, high cross-linking density of paint film, affecting performance and other problems, and achieve short processing time, simple process and easy realization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

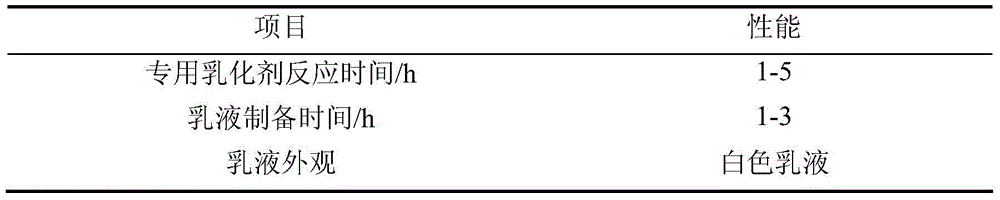

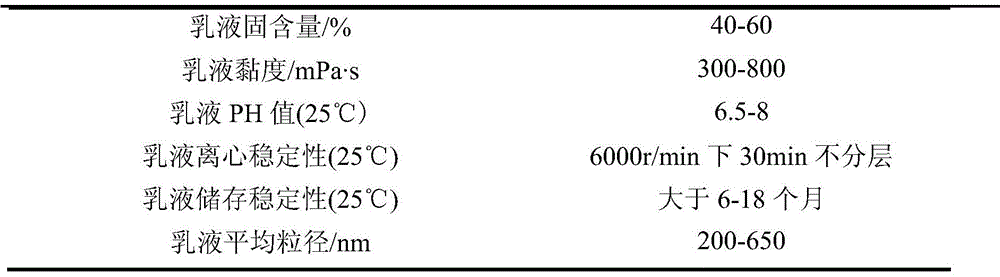

Examples

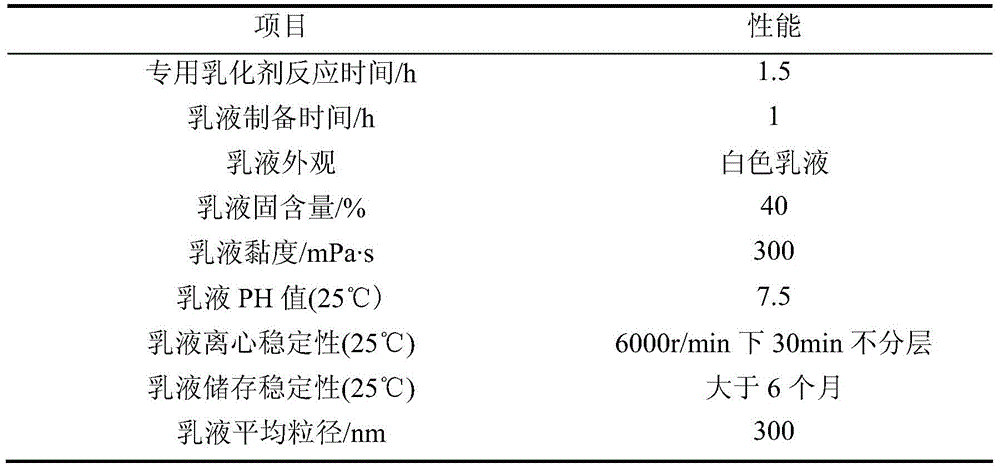

Embodiment 1

[0028] 1. Synthesis of special emulsifier for waterborne solid epoxy resin emulsion

[0029] Put a 2L four-necked flask equipped with a stirrer, a condenser, and a thermometer into a water bath, add 300g of liquid epoxy resin E-35 to the four-necked flask, raise the temperature to 50°C, and then add 300g of polyetheramine D-400 , and stirred for 10 minutes to mix the two evenly.

[0030] Add 3g of aluminum trichloride catalyst to the above mixing system, keep the stirring rate of 300r / min, and react at 60°C for 0.5h.

[0031] Raise the temperature to 80°C, slowly add 300g of polyetheramine D-400 dropwise with a pipette, keep the stirring rate of 300r / min, and react at 80°C for 1 hour to obtain -A-B-A-B-A-B-embedded water-based solid epoxy resin emulsion segmented emulsifier.

[0032] 2. Preparation of aqueous nanoscale solid epoxy resin emulsion

[0033] Add 200g of solid epoxy resin E-20 into a 1L beaker, heat it to 80°C with a heating mantle, add 20g of the appealing wate...

Embodiment 2

[0038] 1. Synthesis of special emulsifier for waterborne solid epoxy resin emulsion

[0039] Put a 5L four-necked flask equipped with a stirrer, a condenser, and a thermometer into a water bath, add 100g of liquid epoxy resin E-44 to the four-necked flask, raise the temperature to 40°C, then add 1000g of polypropylene glycol 4000, and stir for 20 minutes , to mix the two evenly.

[0040] Add 30g of alkyl zinc catalyst to the above mixed system, keep the stirring rate of 300r / min, and react at 60°C for 2h

[0041] Raise the temperature to 90°C, slowly add 1000g of polypropylene glycol 4000 dropwise with a pipette, maintain a stirring rate of 300r / min, and react at 90°C for 2 hours to obtain -A-B-A-B-A-B-block emulsification for water-based solid epoxy resin emulsion agent.

[0042] 2. Preparation of aqueous nanoscale solid epoxy resin emulsion

[0043] Add 200g of solid epoxy resin E-20 into a 1L beaker, heat it to 90°C with a heating mantle, add 30g of the appealing water-b...

Embodiment 3

[0048] 1. Synthesis of special emulsifier for waterborne solid epoxy resin emulsion

[0049] Put a 2L four-necked flask equipped with a stirrer, a condenser, and a thermometer into a water bath. First add 200g of liquid epoxy resin E-31 to the four-necked flask and heat it up to 60°C, then add 500g of polyetheramine D-2000. Stir for 30min to make it evenly mixed.

[0050] Add 10g of alkylaluminum catalyst to the above mixed system, keep the stirring rate of 300r / min, and react at 50°C for 1h.

[0051] Raise the temperature to 90°C, slowly add 500g of polyethylene glycol 2000 dropwise with a pipette, keep the stirring rate of 300r / min, and react at 90°C for 1 hour to obtain the water-based solid epoxy resin emulsion-A-B-C-B-A-B-C-B-block type emulsifier.

[0052] 2. Preparation of aqueous nanoscale solid epoxy resin emulsion

[0053] Add 200g of solid epoxy resin E-20 into a 1L beaker, heat it to 85°C with a heating mantle, add 12g of the appealing water-based solid epoxy re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com