Lutein/lutein ester microparticles and preparation method thereof

A technology of lutein ester and lutein, which can be used in pharmaceutical formulations, ester active ingredients, and cosmetic preparations, etc., can solve problems such as environmental and staff injuries, and achieve solutions that are difficult to emulsify and have excellent storage stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The invention provides a kind of lutein / lutein ester microparticles and its preparation method. The method is prepared by preparing a raw material mixture containing lutein and / or lutein ester, wall material and co-emulsifier under low temperature conditions. A nanoemulsion with a particle size of no more than 1 micron is sprayed onto sucrose starch particles.

[0017] In the above technical solution, the low temperature condition can be limited to 10-35°C, preferably 25-30°C according to the common understanding in the art. The preparation of the nanoemulsion can also adopt methods commonly used in the prior art, and these methods can be exemplified but not limited to colloid mill dispersion and high-pressure homogenization. The sucrose starch granules are used as a carrier and can be prepared according to the records of the prior art according to the requirements of the product. In the present invention, the sucrose starch granules prepared by using a mixture of star...

Embodiment 1

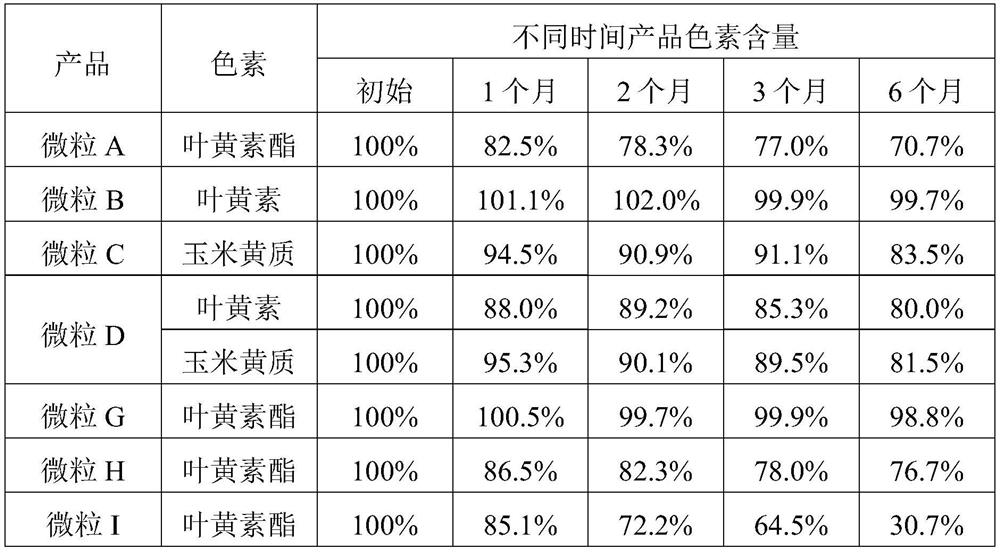

[0031]Add 170g of lutein ester crystals, 20g of ascorbyl palmitate, 30g of sodium ascorbate, and 30g of vitamin E into 200ml of water, and disperse at high speed for 1 hour at 15°C; make 100g of hydroxypropylmethylcellulose into a 6.25% aqueous solution at room temperature, and stir to dissolve Finally, pour it into the high-speed dispersed lutein ester aqueous solution, keep the temperature of the emulsion at 25°C, and stir for 30 minutes; disperse at high speed through a colloid mill to obtain a lutein ester emulsion, and the particle size of the emulsion is D99 / D90 / D50=57.21 / 47.65 / 27.52 μm, spray the emulsion on the surface of 680 g of sucrose-starch granules with a size of 150-200 μm in the form of spray coating. After the lutein ester emulsion wraps the sucrose-starch granules layer by layer, the formed lutein ester microparticle A (theoretical content is 12.2%) has a content of 12.1%, a surface pigment content of 9.8%, and a bulk density of 0.60 g / ml. Its pigment retent...

Embodiment 2

[0033] Dissolve 16.7g of pullulan in 200ml of water, add 90g of lutein crystals, 20g of ascorbyl palmitate, 30g of ascorbyl stearate, 30g of dl-α-tocopherol, and disperse at a high speed for 1 hour at 25°C; 133.3 g of hydroxypropyl methylcellulose was configured into a 6.25% aqueous solution, stirred and dissolved, poured into a high-speed dispersed lutein aqueous solution, and kept the temperature of the emulsion at 25°C, and stirred for 30 minutes; the lutein emulsion was obtained by high-speed dispersion through a colloid mill. The particle size of the emulsion is D99 / D90 / D50=0.90 / 0.75 / 0.21 μm, and the emulsion is sprayed on the surface of 680 g of starch-sugar particles with a size of 180-300 μm in the form of spray coating. After the lutein emulsion wraps the sucrose starch granules layer by layer, lutein particles B (theoretical content is 6.3%) are formed, the content is 6.4%, the surface pigment content is 0.1%, and the bulk density is 0.75g / ml. Its pigment retention r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com