Tough and high modulus silicone resin composition and preparation method thereof

A technology of silicone resin composition and high modulus, which is applied in the field of silicone resin composition with high toughness and high modulus and its preparation, and can solve the problems of small dosage range of unsaturated carboxylate, small compression modulus, and difficulty in meeting the requirements of precision instruments and meters. Cushioning and shock absorption and vibration isolation requirements and other issues, to achieve the effect of good appearance and uniform interior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The preparation method of high modulus silicone resin composition of the present invention is characterized in that comprising the following steps:

[0071] a. Mixing of organopolysiloxane, silica powder and necessary dispersant

[0072] The specific surface area (BET method) of organopolysiloxane with a viscosity-average degree of polymerization of 4000 or more is not less than 50m 2 / g of silica powder reinforcing agent, necessary silica dispersant and weak reinforcing fillers such as Baiyanhua, diatomaceous earth, etc., are mixed together by using a rubber mixer, internal mixer or kneader, and then The organopolysiloxane reinforcing base is obtained by heat-treating the obtained mixture by means of a kneader or a drier, or vacuumizing at high temperature in a kneader to expel small molecules. The purpose of heat treatment is to remove volatile components and accelerate the reaction between silica powder and dispersant. The temperature or heating time of the heat tre...

Embodiment -

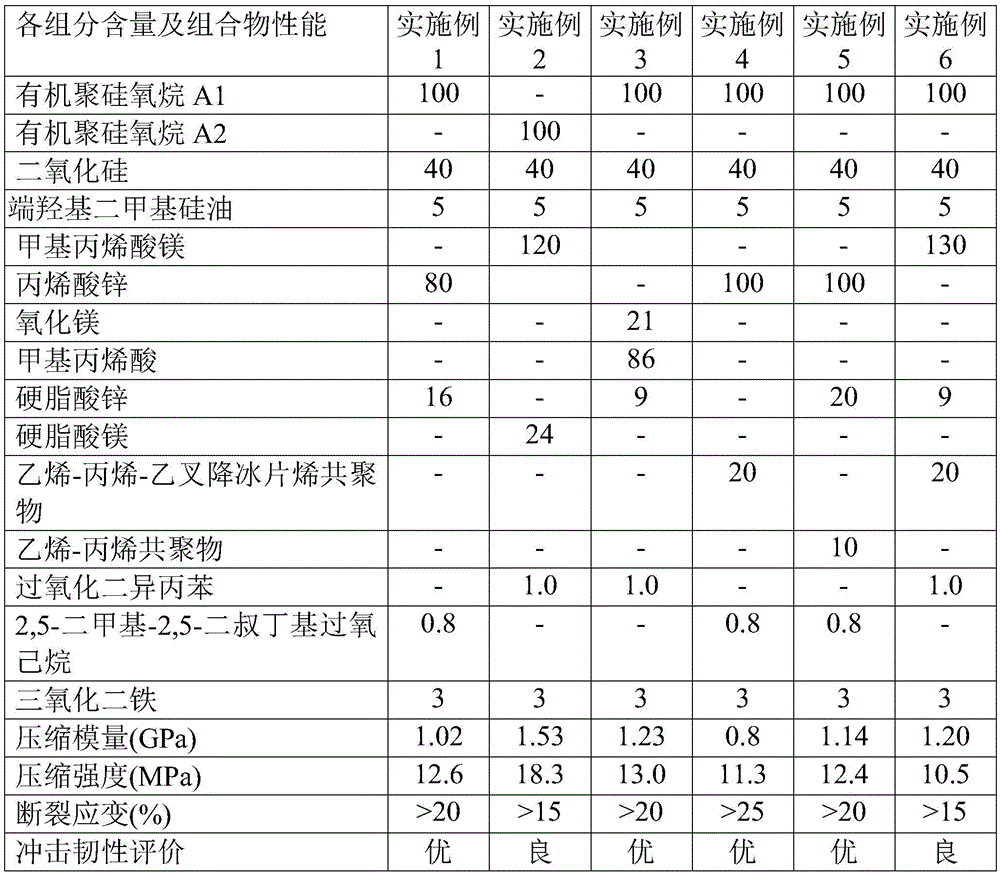

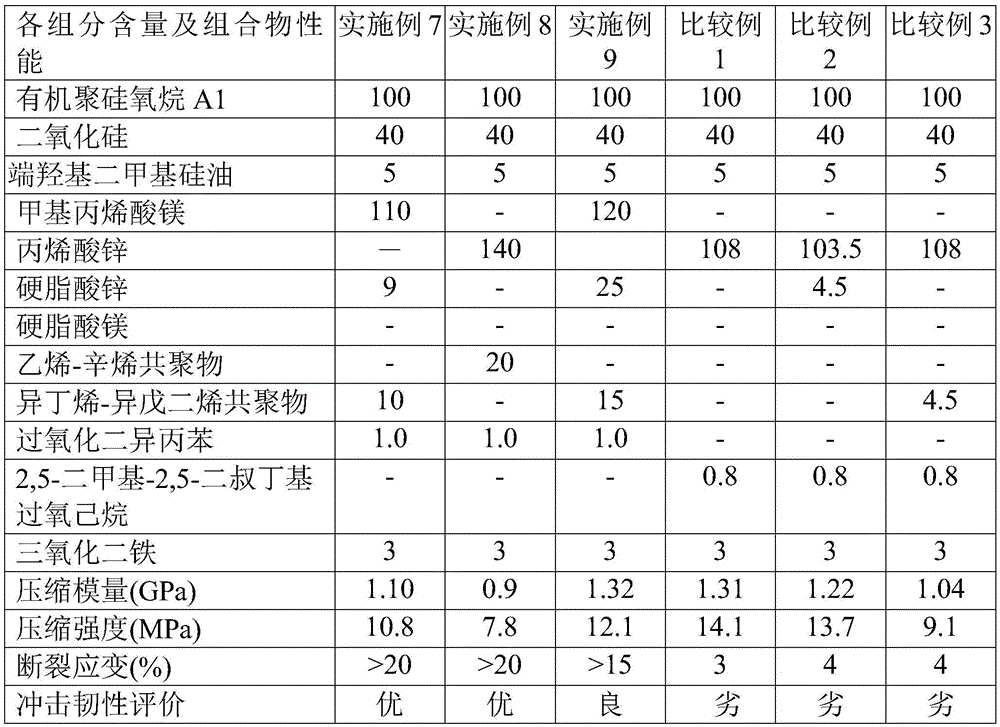

[0083] The present invention is specifically described below with a series of examples and comparative examples, but the present invention is not limited by the following examples in any way. In the following examples, "part" means "part by mass".

Embodiment 1

[0085] The organic Polysiloxane, 40 parts BET specific surface area is 195m 2 / g of dry silica AS-200 (trade name, manufactured by Shenyang Chemical Co., Ltd.), and 5 parts containing silanol groups at both ends, and a viscosity of 29mm 2 / s (23° C.) dimethyl polysiloxane was added to a kneader, and heated and kneaded at 180° C. for 2 hours to obtain a polysiloxane material.

[0086] To 140 parts of the polysiloxane base thus prepared was added:

[0087] 80 parts zinc acrylate (particle size less than 5 microns, purity 88%);

[0088] 0.8 parts of 2,5-dimethyl-2,5-di-tert-butylperoxyhexane (purity 95%) as curing agent;

[0089] 3 parts of ferric oxide (purity 98%) as a heat-resistant additive;

[0090] 16 parts fatty acid zinc (analytical pure).

[0091] The resulting mixture was thoroughly mixed sequentially in a two-roll mill to obtain a silicone resin composition. Then the composition is molded at 165° C. to form a square plate, a circular plate, a cylinder or products...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com