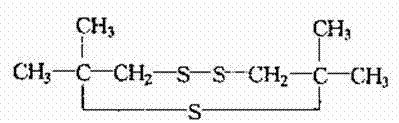

Neopentyl polyol ester automobile gear lubricating oil containing sulphurized isobutylene

A polyol ester, automotive gear technology, applied in the field of gear lubricants, can solve problems such as corrosion, and achieve the effect of good extreme pressure and anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A neopentyl polyol ester automotive gear lubricating oil containing thienyl polyol ester, which is based on neopentyl polyol ester and added ester weight percentage: T321 is 0.35%; RC2540 is 0.39%; P120 is 0.32%, after mixing Made evenly.

Embodiment 2

[0044] A neopentyl polyol ester automotive gear lubricating oil containing thienyl polyol ester, which is based on neopentyl polyol ester and added with ester weight percentage: T321 is 0.05%; RC2540 is 0.03%; P120 is 0.02%, after mixing Made evenly.

Embodiment 3

[0046] A neopentyl polyol ester automotive gear lubricating oil containing thienyl polyol ester, which takes neopentyl polyol ester as the base oil and adds ester weight percentage: T321 is 0.2%; RC2540 is 0.3%; P120 is 0.1%, after mixing Made evenly.

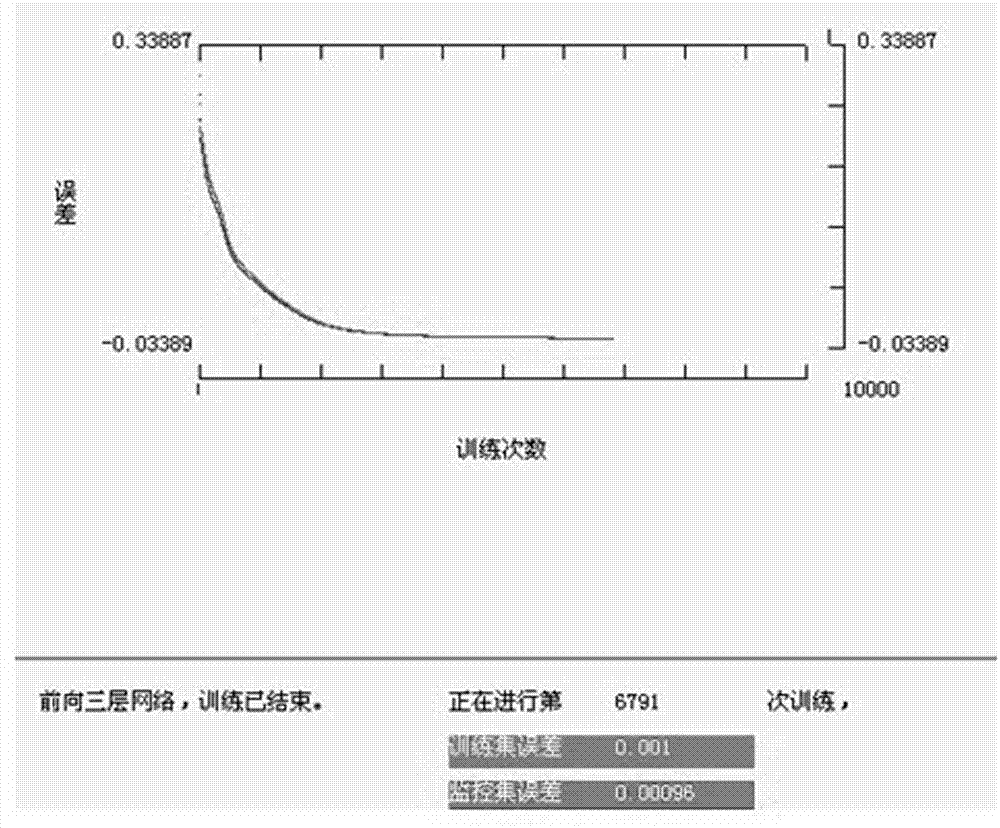

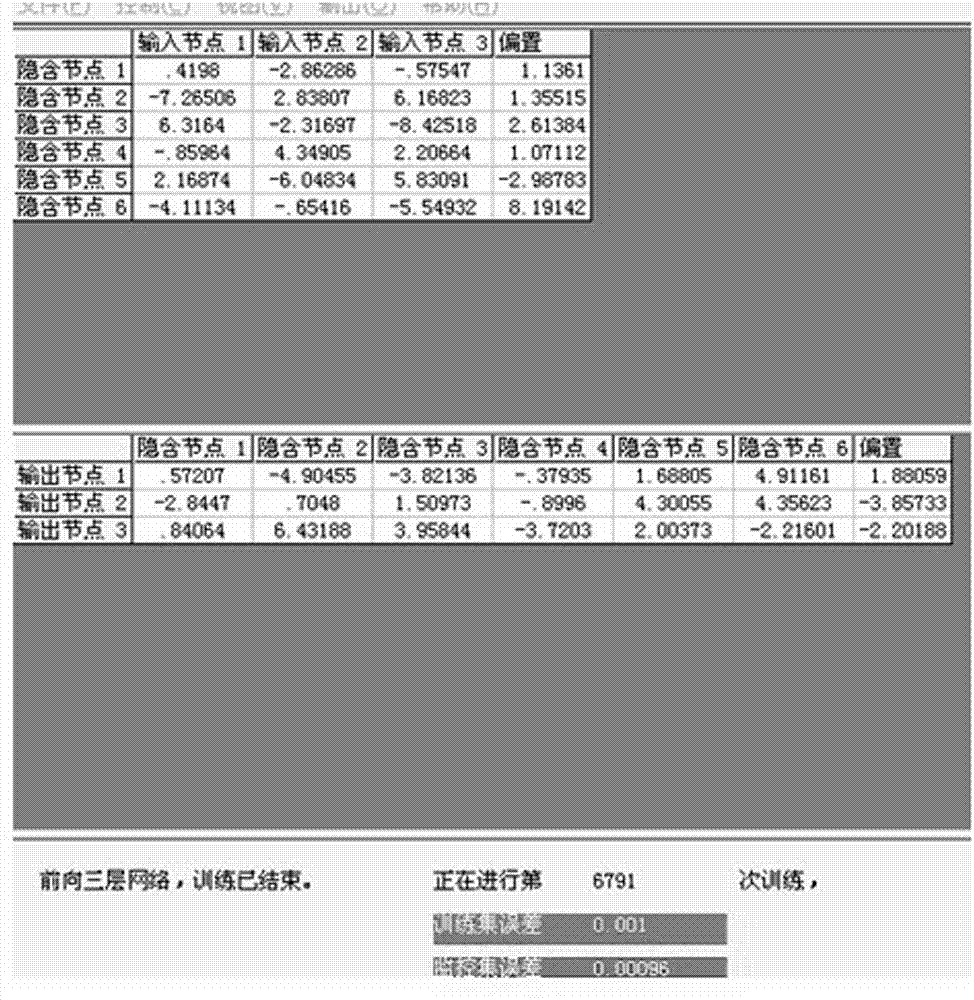

[0047] Prediction and verification of T321, RC2540, P1 20 added to neopentyl polyol esters.

[0048] Lubricating oil additive formula selection X 1 = T321,X 2 =RC2540,X 3 =P120(X1,X 2 and x 3 Mass percent) a total of 3 factors and 7 levels were investigated, and neopentyl polyol ester was used as the base oil. The investigation target is the dependent variable Y 1 =Pb,Y 2 = , Y 3 = , Y 1 is the maximum no-seize load, which indicates the load carrying capacity, Y 2 For sintering loads indicate the ultimate load carrying capacity at and Y 3 It is expressed as the wear scar of the test ball when the load is 294N and the wear time is 20min. Experimental result Y 1 = The minimum value is 1577N, the initial value Pb ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com