High purity smelting method for nickel-based high-temperature alloy

A technology of nickel-based superalloy and smelting method, which is applied in the direction of improving energy efficiency and process efficiency, and can solve the problems of lowering refining temperature, shortening refining time, and poor desulfurization effect, so as to reduce refining temperature and shorten refining time , the effect of short refining time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

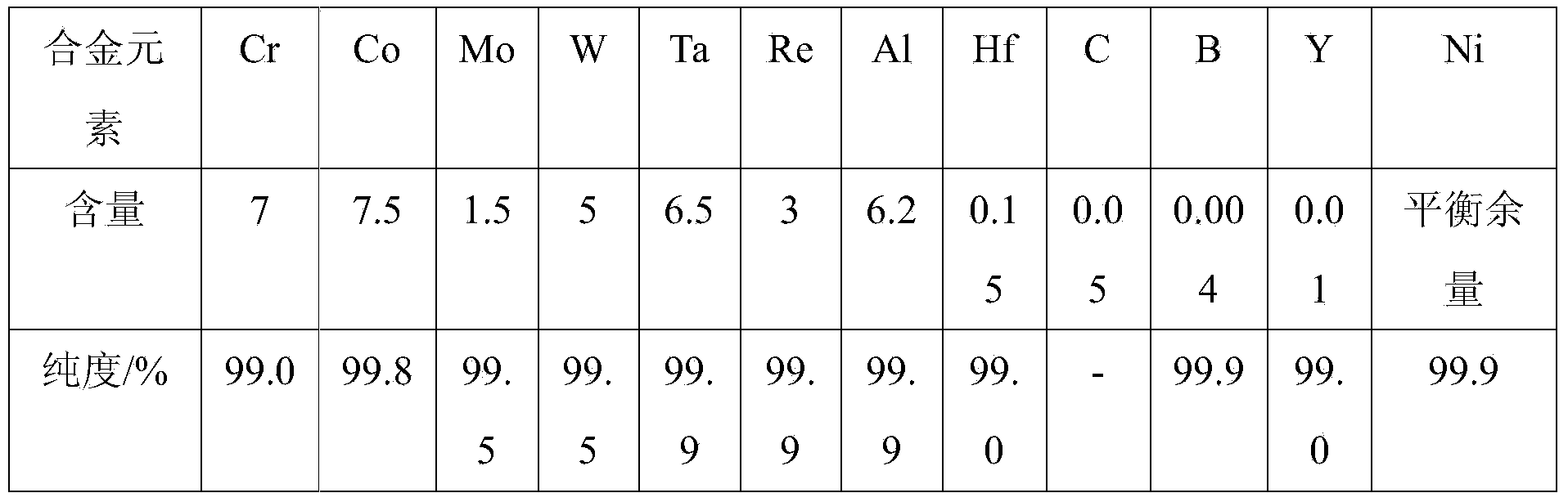

[0031] The composition of this embodiment is shown in Table 1

[0032] Table 1

[0033]

[0034] The first step: melting of the alloy

[0035] (1) Furnace loading

[0036] In the water-cooled copper crucible from bottom to top, 40% Ni, all Co, all Re, all C, all Mo, all W, all Cr, all Ta, all Hf and 30% Ni were loaded in sequence.

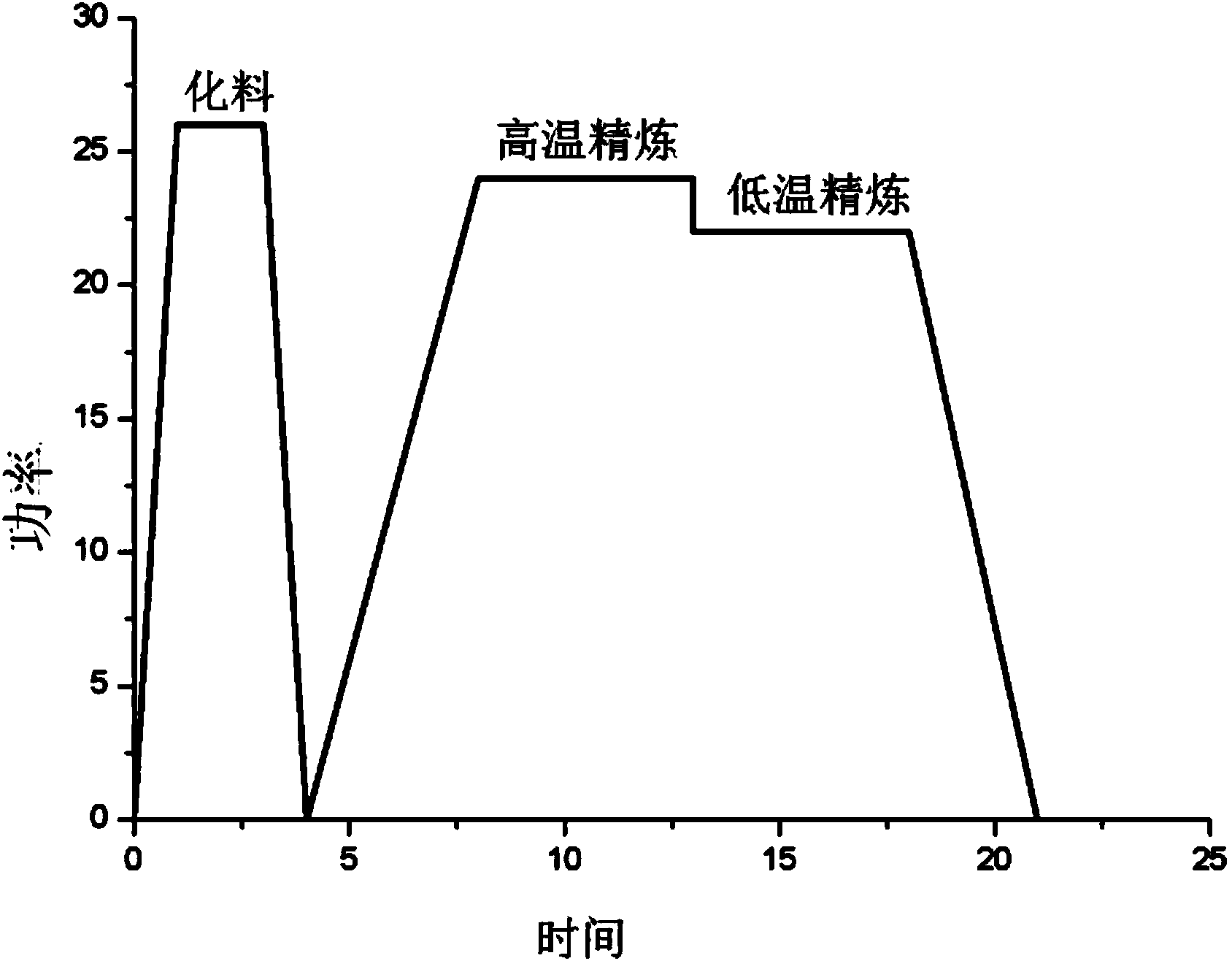

[0037] (2) Alloy melting

[0038] Vacuum induction melting furnace is used for melting, when the vacuum degree of vacuum induction melting furnace reaches 1×10 -2 At P a, remove the attached gas by heating with low power; when the vacuum reaches 5×10 -3 At Pa, pass high-purity argon to 0.1MPa, rapidly heat up at a heating rate of 60°C / s until the charge is completely melted, and then cool down with the furnace.

[0039] Step 2: Alloy Refining

[0040] (1) Furnace loading

[0041] The alloy ingot melted in the first step, the Al-Y master alloy and the Ni-B master alloy are successively loaded into a water-cooled copper crucible.

[0042] ...

Embodiment 2

[0052] The composition of this embodiment is shown in Table 5

[0053] table 5

[0054]

[0055] The first step: melting of the alloy

[0056] (1) Furnace loading

[0057] In the water-cooled copper crucible from bottom to top, 50% Ni, all Co, all C, all Mo, all W, all Cr, all Ta, all Hf and 20% Ni were loaded in sequence.

[0058] (2) Alloy melting

[0059] Vacuum induction melting furnace is used for melting, when the vacuum degree of vacuum induction melting furnace reaches 1×10 -2 At P a, remove the attached gas by heating with low power; when the vacuum reaches 5×10 -3 At Pa, pass high-purity argon to 0.1MPa, rapidly heat up at a heating rate of 60°C / s until the charge is completely melted, and then cool down with the furnace.

[0060] Step 2: Alloy Refining

[0061] (1) Furnace loading

[0062] The first step alloy ingot, Al-Y master alloy, and Ni-B master alloy are successively loaded into a water-cooled copper crucible.

[0063] (2) Alloy refining

[0064] Re...

Embodiment 3

[0071] Adopt the alloy composition identical with embodiment 2

[0072] The first step: melting of the alloy

[0073] (1) Furnace loading

[0074] In the water-cooled copper crucible from bottom to top, 50% Ni, all Co, all C, all Mo, all W, all Cr, all Ta, all Hf and 20% Ni were loaded in sequence.

[0075] (2) Alloy melting

[0076] Vacuum induction melting furnace is used for melting, when the vacuum degree of vacuum induction melting furnace reaches 1×10 -2 Pa, remove the attached gas by heating with low power, when the vacuum reaches 5×10 -3 At Pa, pass high-purity argon to 0.1MPa, rapidly heat up at a heating rate of 60°C / s until the charge is completely melted, and then cool down with the furnace.

[0077] Step 2: Alloy Refining

[0078] (1) Furnace loading

[0079] The first step alloy ingot, Al-Y master alloy, and Ni-B master alloy are successively loaded into a water-cooled copper crucible.

[0080] (2) Alloy refining

[0081] Refined by high-frequency vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com