Solid scaly pulp electrolytic cathode device

A slurry electrolysis, fish scale technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of affecting the size of the incoming current and restricting the production capacity, so as to increase the electrode area, improve the production capacity, and improve the leaching rate and current. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

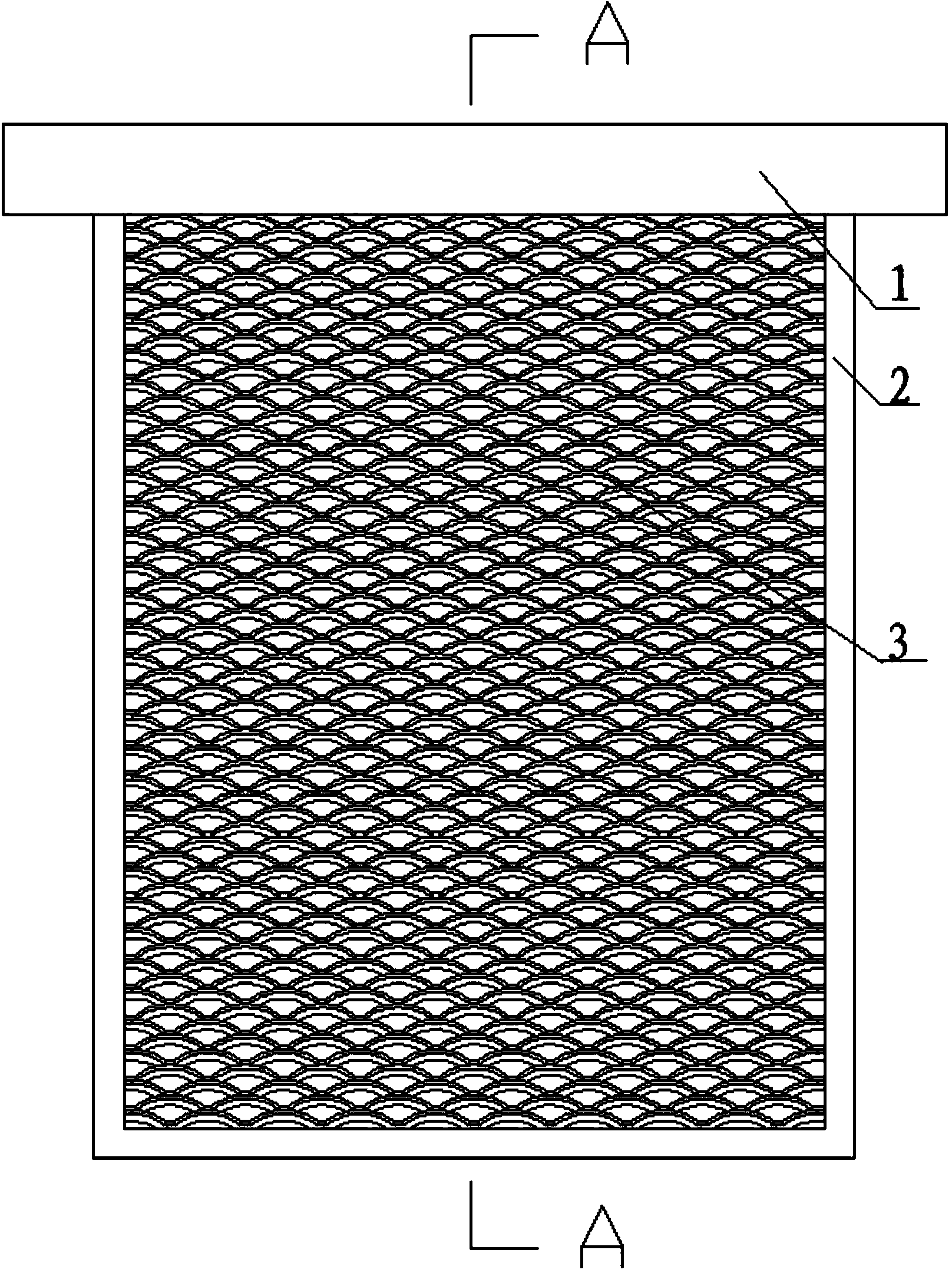

[0014] The preferred embodiment of the three-dimensional fish scale-shaped pulp electrolysis cathode device of the present invention is:

[0015] It includes a conductive copper tube, one side of the conductive copper tube is connected with a cathode frame, and the cathode frame is provided with three-dimensional scale-like holes.

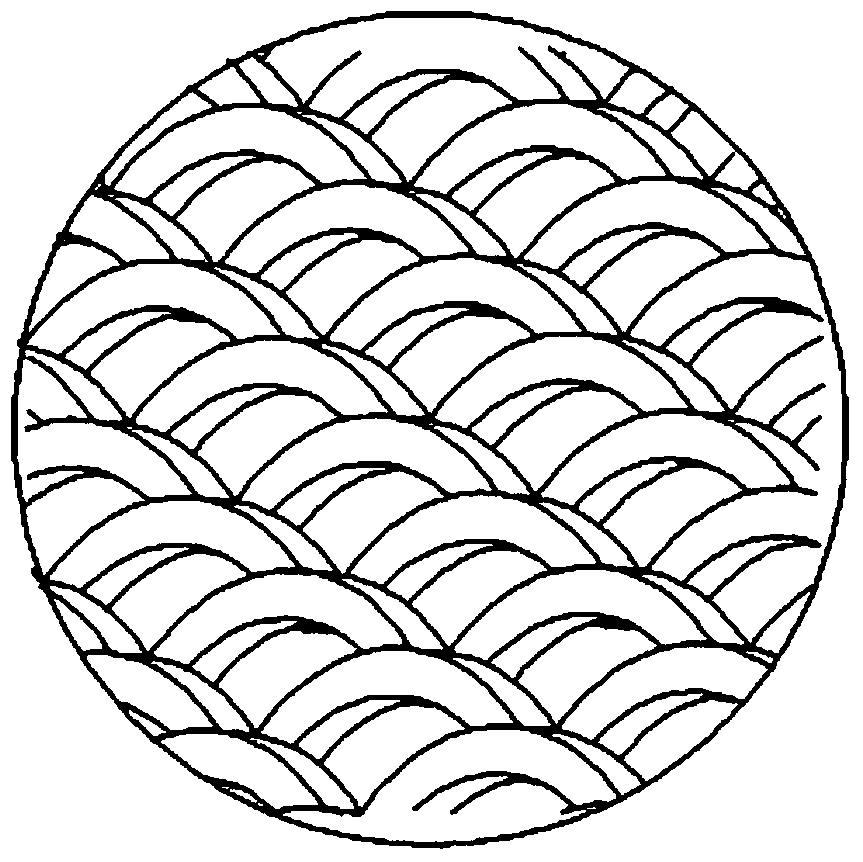

[0016] The three-dimensional scale-shaped holes include multiple rows of arc structures, the lower row of arc structures and the upper row of arc structures are alternately arranged, and the arc tops of the lower row of arc structures press against the ends of the upper row of arc structures.

[0017] The porosity of the three-dimensional scale-shaped holes is 25%-50%.

[0018] The specific surface area of the three-dimensional scale-shaped pores is 1.2 to 1.5 times that of the plane openings.

[0019] The three-dimensional fish-scale electrolysis cathode device of the present invention has three-dimensional fish-scale electrodes, which can incr...

specific Embodiment

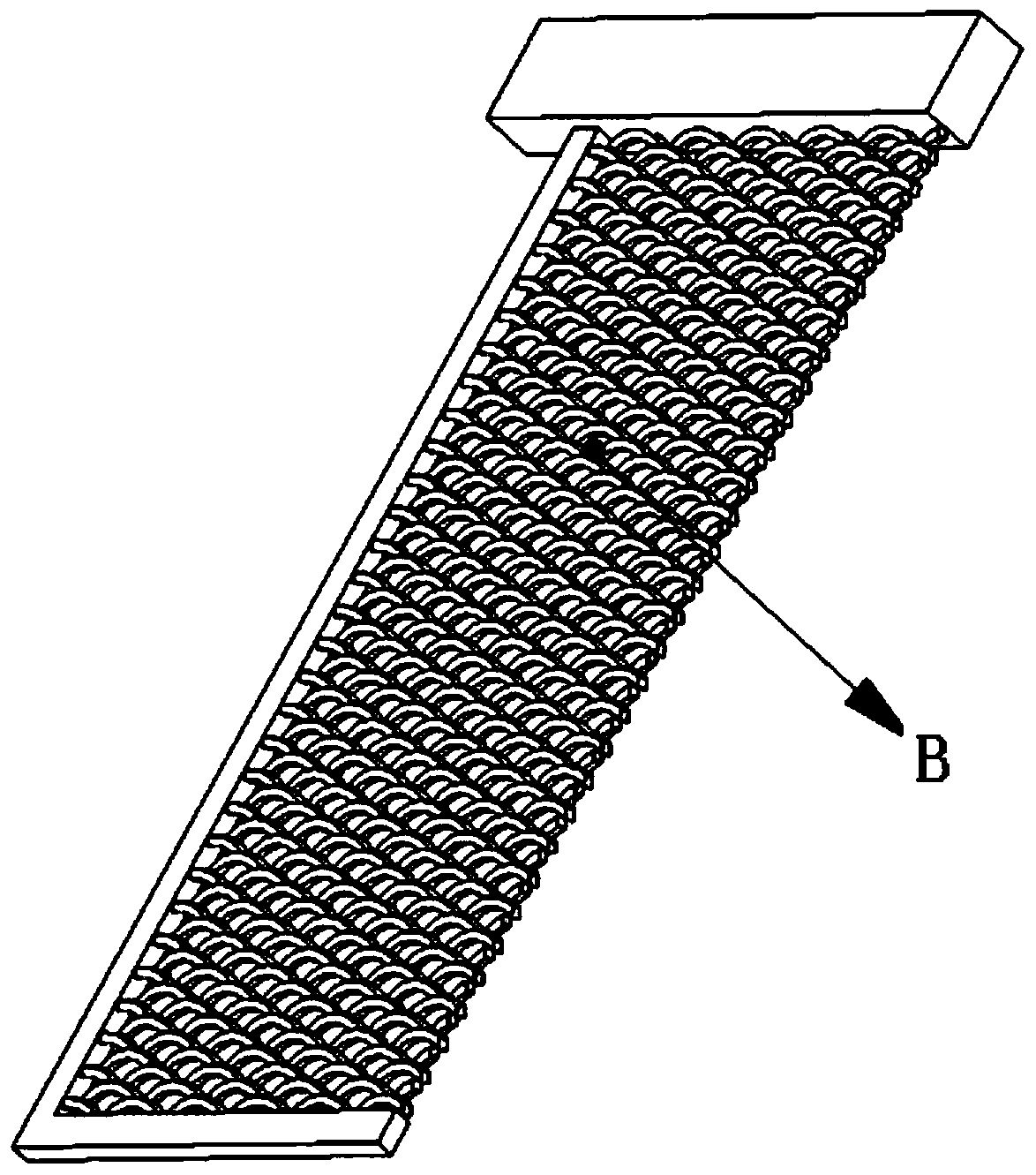

[0020] Such as figure 1 , figure 2 , image 3 As shown, it includes a conductive copper tube 1, one side of the conductive copper tube 1 is connected to a cathode frame 2, and a three-dimensional scale-shaped hole 3 is provided in the cathode frame 2. While increasing the electrode area, the electrolyte can pass through the three-dimensional scale-shaped holes 3 of the cathode electrode, reducing the concentration gradient and improving the current efficiency.

[0021] The opening ratio of the cathode electrode is 25% to 50%, and the three-dimensional scale-like holes 3 increase the specific surface area by 1.2 to 1.5 times compared with ordinary openings.

[0022] It is applied to the electrolytic antimony smelting of ore slurry. After the antimony in the electrolyte is precipitated in the cathode, the electrolyte passes through the three-dimensional scale-like holes 3 in the cathode frame 2, which acts as a diversion, reduces the influence of the concentration gradient, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com