Method for mounting side seal plates of drum strainer

An installation method and side sealing plate technology are applied in construction, building structure, construction material processing and other directions, which can solve the problems of waste of manpower and material resources, low work efficiency, and high safety risks, and reduce workload and welding workload. , the effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

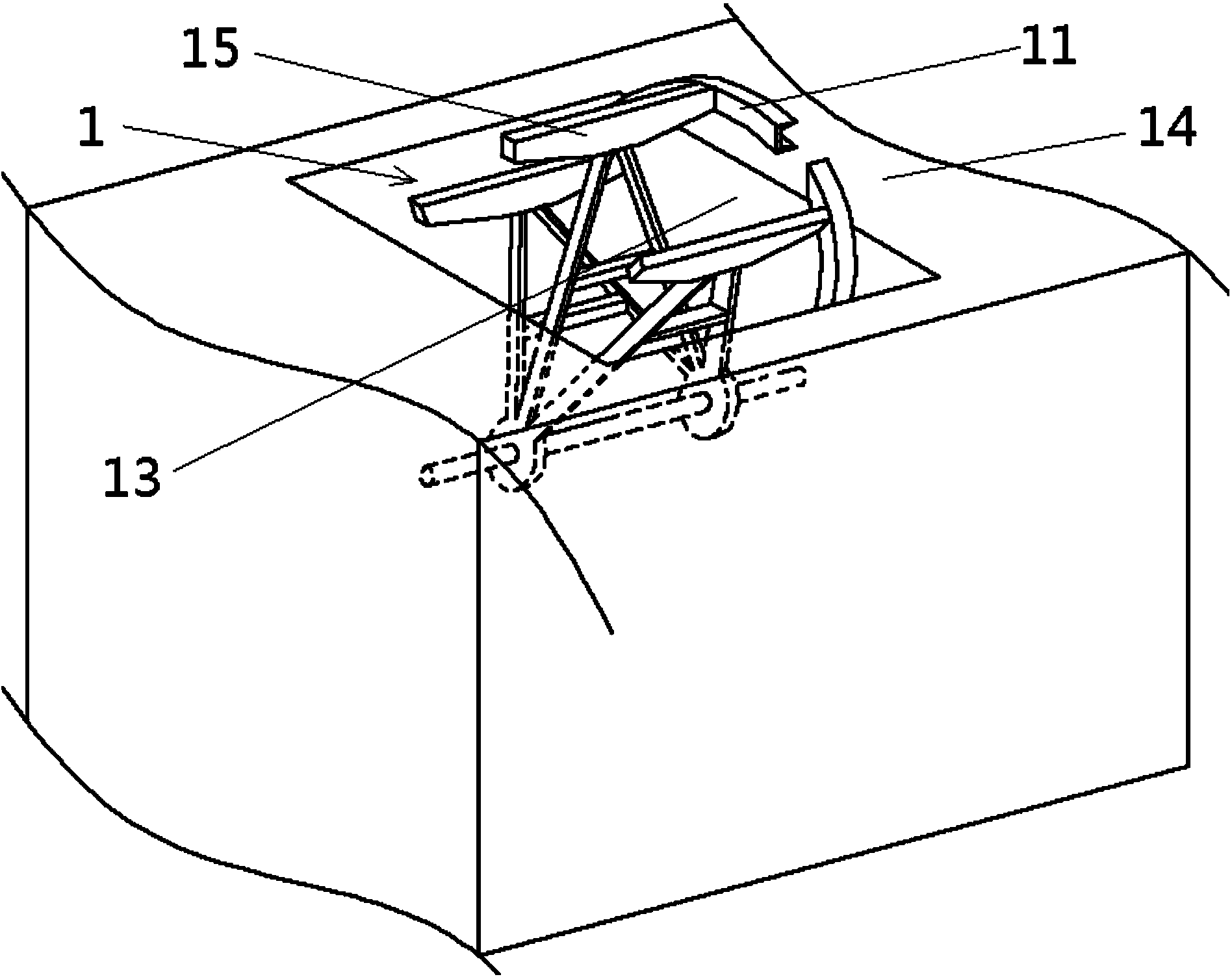

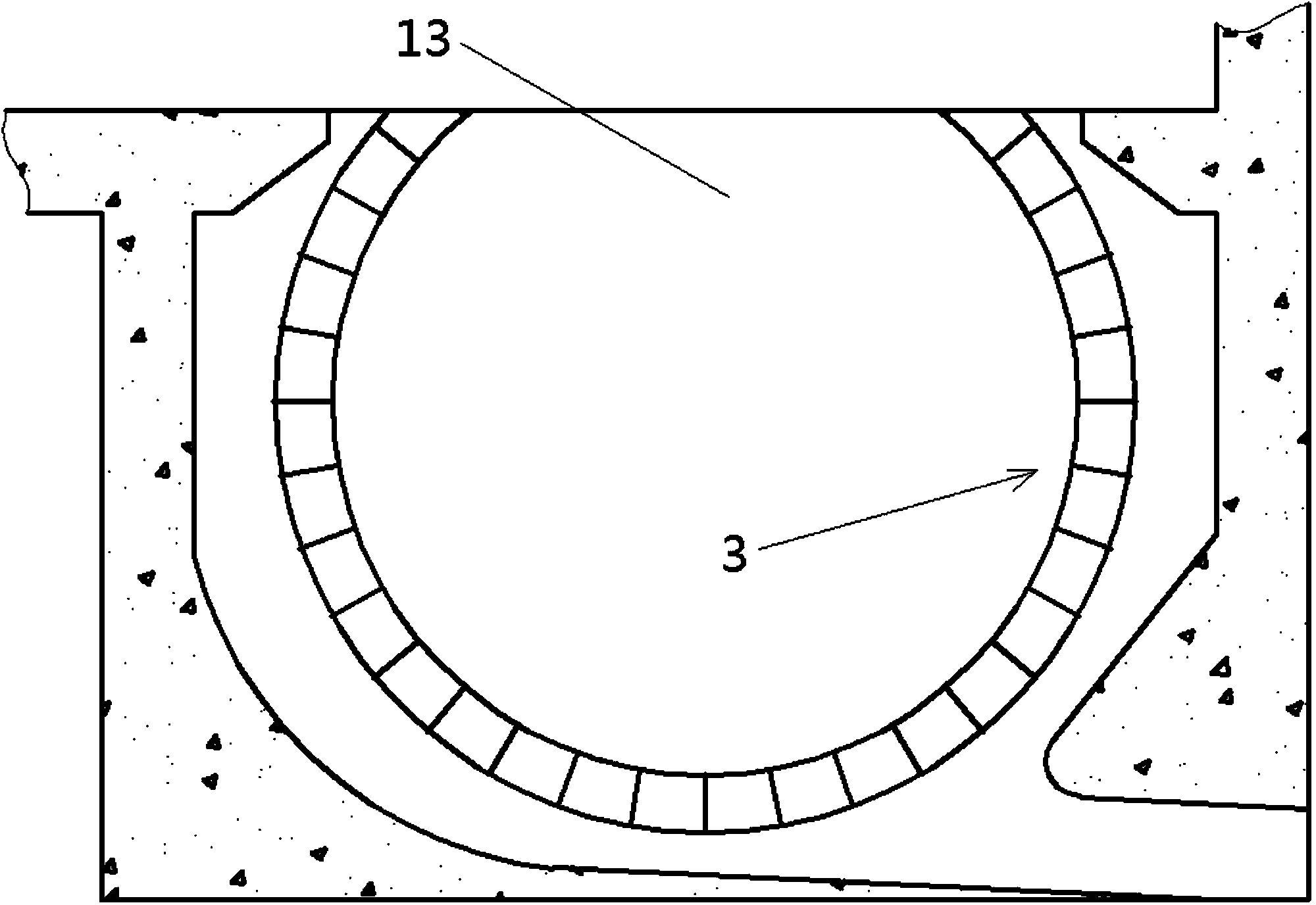

[0024] Such as figure 1 , figure 2 , image 3 as well as Figure 4 As shown, a drum filter side sealing plate installation method, the method includes the following steps:

[0025] The first step is to install the drum-shaped filter screen 1 in the pool 14 with embedded boards 2 on both sides of the wall, measure the side frame of the drum-shaped filter screen 1 after adjusting the drum-shaped filter screen 1 according to the installation requirements 11 axial runout value.

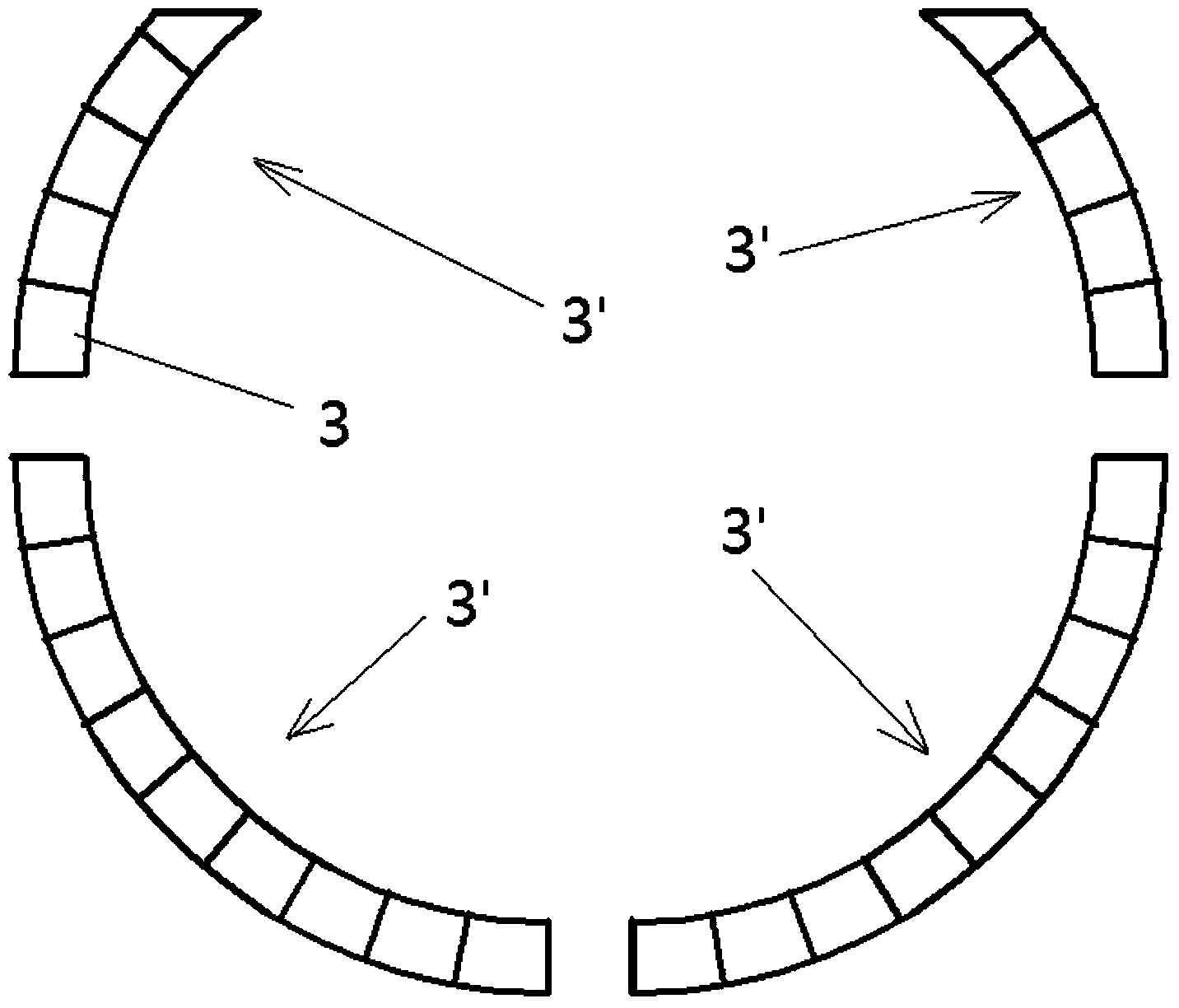

[0026]In the second step, several pieces of side sealing plates 3 are first welded and spliced end to end to form four such as image 3 The shown side sealing plate group 3', and the welds of these four side sealing plate groups 3' are ground flat, at the place where the measured axial end face runout value of the drum-shaped filter screen 1 is the largest, as Figure 4 As shown, each side sealing plate 3 in a group of side sealing plate groups 3' that has been welded and spliced is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com