Double cooling system of X-ray machine

A dual-cooling, X-ray machine technology, used in refrigerators, compressors, refrigeration components, etc., can solve the problems of high operating costs, large cooling capacity, and decreased cooling efficiency, and achieve the goal of reducing operating costs and downtime. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

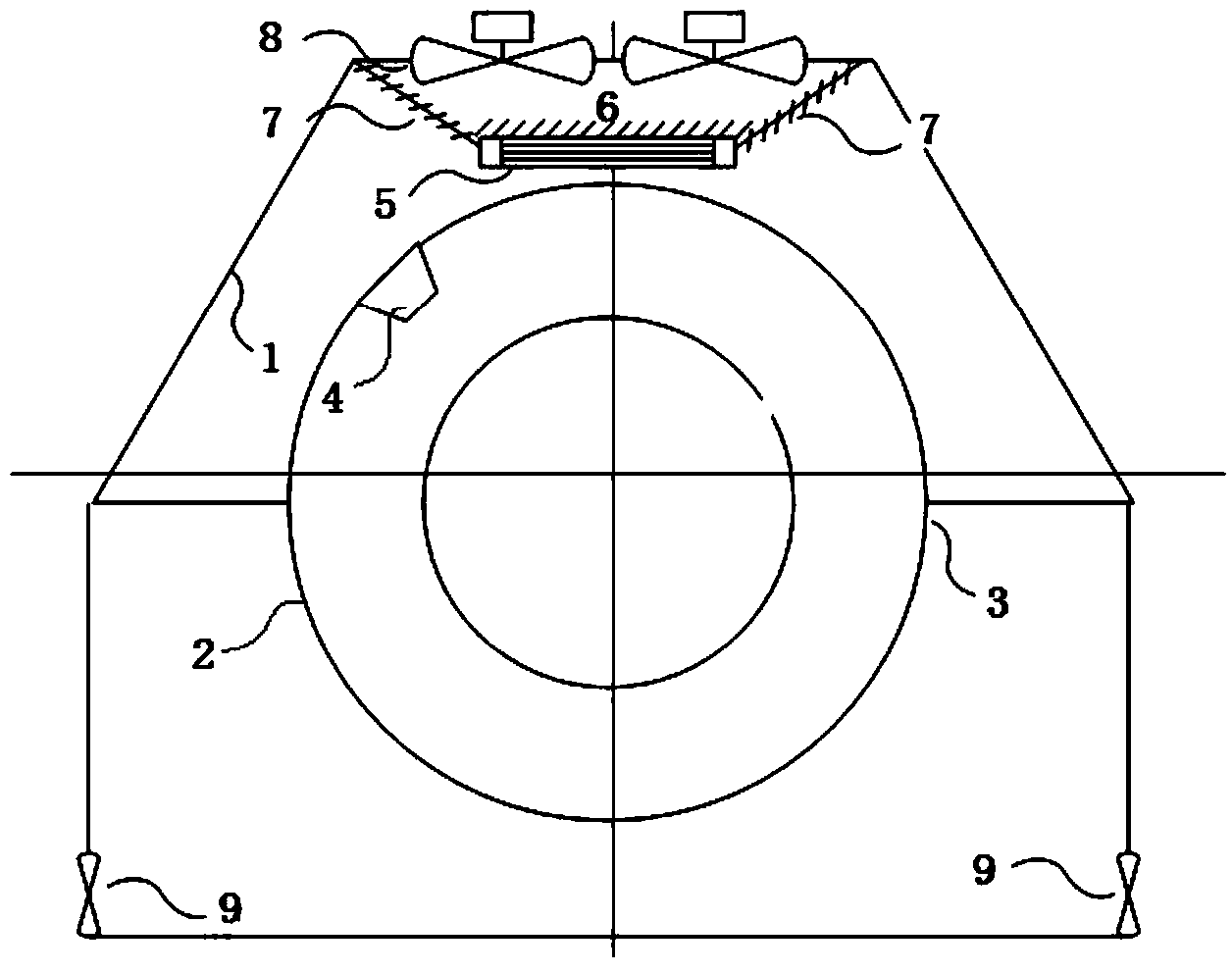

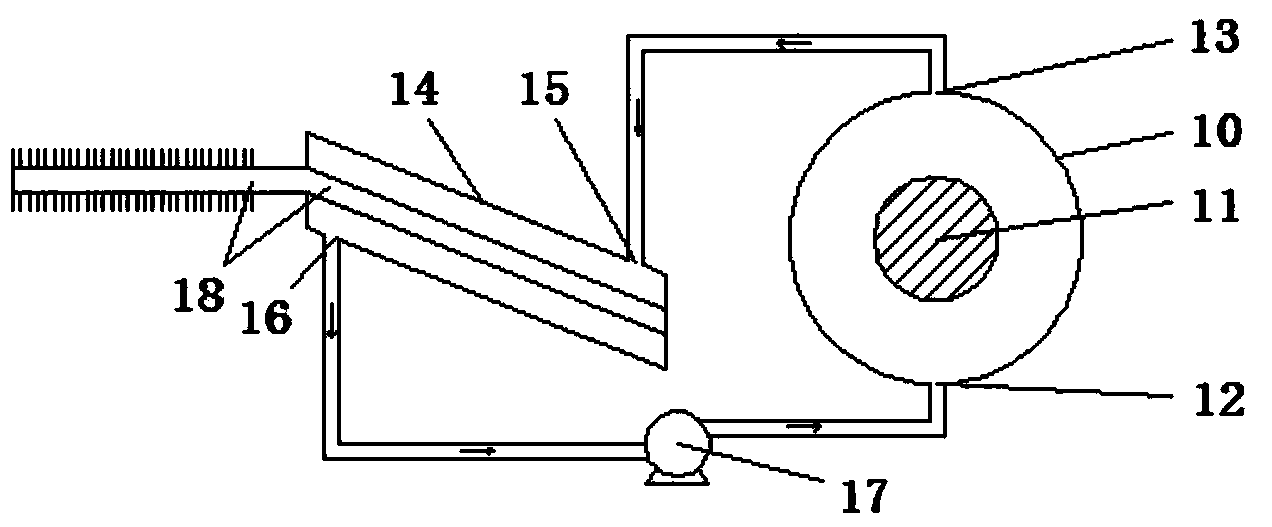

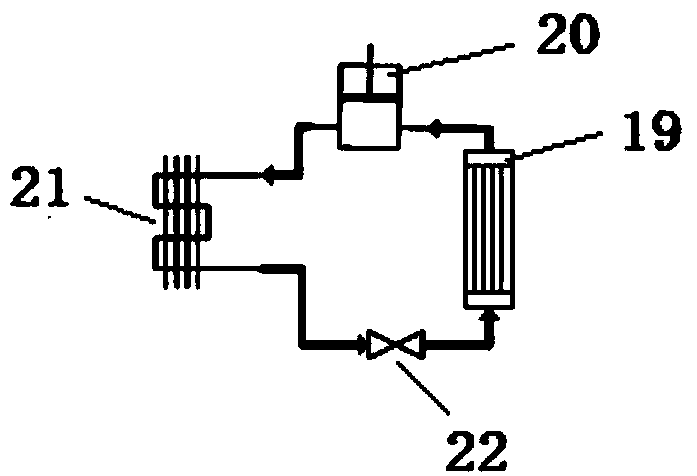

[0036] See Figure 1 ~ Figure 3 , which illustrates the dual cooling system of an X-ray machine according to an embodiment of the present invention, comprising: an inner hollow housing 1; an annular housing 2 located inside the housing 1, which is provided with a cavity, and the annular housing 2 The outer surface is provided with a plurality of vents for heat dissipation at intervals; the bracket 3 is fixed on the inner side of the housing 1 for supporting and fixing the annular housing 2; the liquid cooling system 4 of the X-ray tube is connected with the X-ray tube 11 Commonly fixed in the cavity of the annular housing 2, the liquid cooling system 4 of the X-ray tube and the X-ray tube 11 rotate around the axis of the annular housing 2; the pre-cooling system 5, its functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com